Method for preparing Bi-2223-Ag multi-core superconductive strip material by adding nano-copper

A technology of bi-2223 and superconducting strips, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc. Expensive equipment and other issues, to achieve the effect of improving the uniformity of current carrying, avoiding pollution, and avoiding the influence of core wire density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

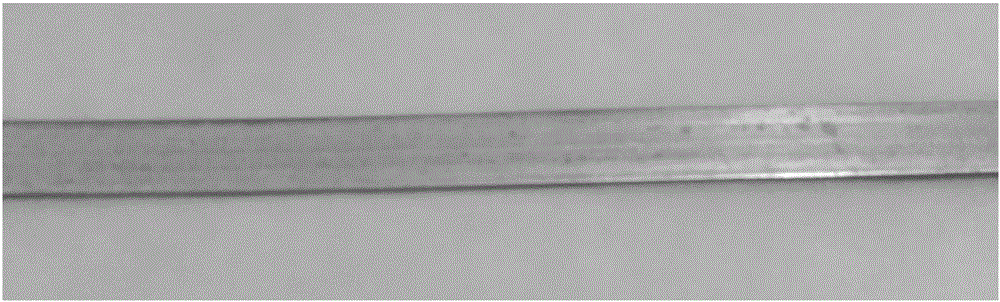

Image

Examples

Embodiment 1

[0026] The preparation method of the Bi-2223 / Ag multi-core superconducting tape of this embodiment includes the following steps:

[0027] Step 1. Use conventional co-precipitation method to prepare Bi-2223 precursor powder with low copper content. After sintering the precursor powder, add nano-copper powder to the sintered precursor powder so that the mass content of copper in the precursor powder reaches the theoretical mass content. Under the protection of argon, the precursor powder added with nano-copper powder is ball-milled and uniformly mixed to obtain a tube-filled precursor powder; the copper underweight Bi-2223 precursor powder means that the quality of copper in the precursor powder is the theoretical mass of copper in Bi-2223 The mass purity of the nano copper powder is not less than 99.9%, the particle size is not more than 50nm; the volume purity of the argon gas is not less than 99.99%, the ball-to-battery ratio in the ball milling process is 2:1, and the ball milli...

Embodiment 2

[0037] The preparation method of the Bi-2223 / Ag multi-core superconducting tape of this embodiment includes the following steps:

[0038] Step 1. Use conventional co-precipitation method to prepare Bi-2223 precursor powder with low copper content. After sintering the precursor powder, add nano-copper powder to the sintered precursor powder so that the mass content of copper in the precursor powder reaches the theoretical mass content. Under the protection of argon, the precursor powder added with nano-copper powder is ball-milled and uniformly mixed to obtain a tube-filled precursor powder; the copper underweight Bi-2223 precursor powder means that the quality of copper in the precursor powder is the theoretical mass of copper in Bi-2223 The mass purity of the nano copper powder is not less than 99.9%, the particle size is not more than 50nm; the volume purity of the argon gas is not less than 99.99%, the ball-to-battery ratio in the ball milling process is 5:1, and the ball milli...

Embodiment 3

[0045] The preparation method of the Bi-2223 / Ag multi-core superconducting tape of this embodiment includes the following steps:

[0046] Step 1. Use conventional spray pyrolysis method to prepare Bi-2223 precursor powder with insufficient copper content. After sintering the precursor powder, add nano-copper powder to the sintered precursor powder so that the mass content of copper in the precursor powder reaches the theoretical mass content. Then, under the protection of argon gas, the precursor powder added with nano-copper powder is ball-milled and mixed uniformly to obtain a tube-filled precursor powder; the copper under-quantity Bi-2223 precursor powder means that the quality of copper in the precursor powder is the copper theory in Bi-2223 94% of the mass; the mass purity of the nano copper powder is not less than 99.9%, the particle size is not more than 50nm; the volume purity of the argon gas is not less than 99.99%, the ball-to-battery ratio in the ball milling process i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com