Dynamic thermal mechanical analysis method for measuring phase transition temperature of temperature-sensitive hydrogel

A temperature-sensitive hydrogel and dynamic thermomechanical technology, applied in the thermal development of materials, etc., can solve the problems of gel strength reduction, difficulty in removal, fragility and breakage when taking out and weighing, and achieve simple test operation and simple and intuitive data , the effect of small sample size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

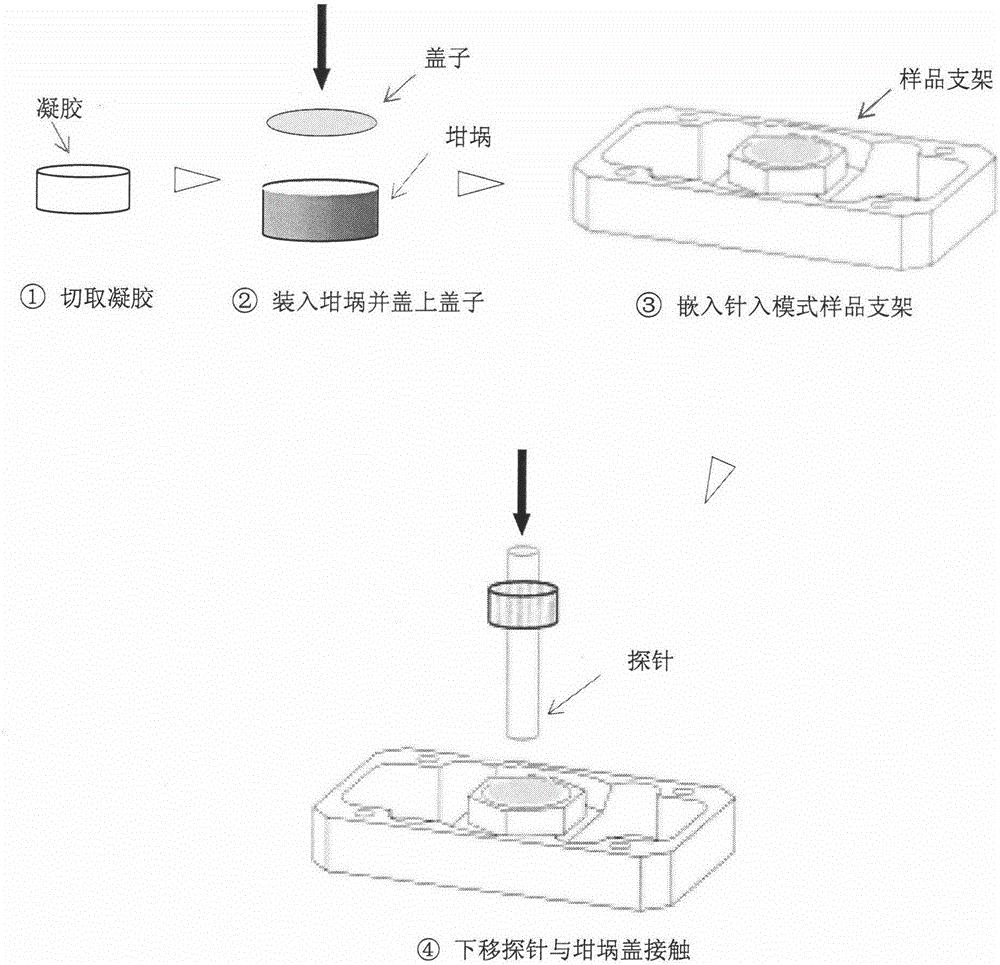

[0020] On the columnar or massive PNIPAm nanocomposite hydrogels, the diameter is 8.0mm, and the sample height is 3.0mm; The thickness of the cover is 0.2mm), cover the matching crucible cover, and then embed it into the sample tray of the needle penetration mode probe, adjust the contact between the probe and the center of the crucible cover, set the temperature rise range to 0-70°C, and the temperature rise rate The temperature is 1°C / min, and the vibration frequency is 1Hz. After the initial temperature is balanced, start to measure and record the temperature rise curve.

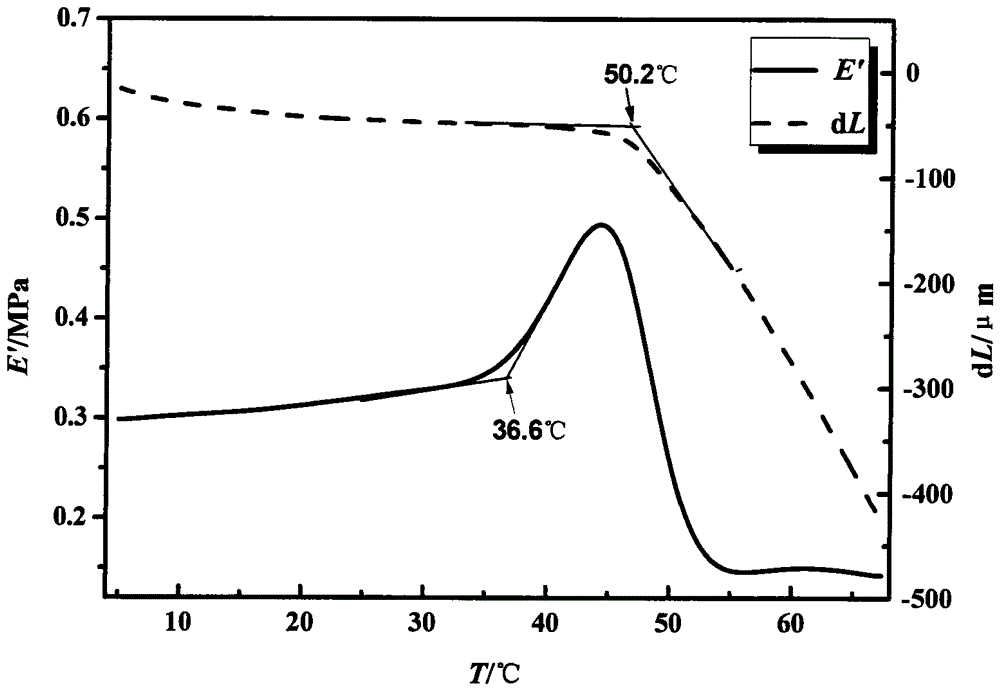

[0021] Carry out DMA test to water-containing hydrogel according to above-mentioned test method, obtain storage modulus (E ')-temperature (T) curve and deformation (dL)-temperature (T) curve of material [see figure 2 ]. From the storage modulus (E')-temperature (T) curve in the figure, it can be seen that the storage modulus (E') has a significant increase in the phase transition temperature (around 36....

Embodiment 2

[0024] On the columnar or massive PNIPAm nanocomposite hydrogel, cut out a diameter of 6.0mm and a cylindrical sample with a height of 1.5mm; the sample to be tested is placed in a flat-bottomed aluminum crucible (diameter 6.3mm, height 1.8 mm) used by the DSC instrument of the American PE company. mm, wall thickness and cover thickness are both 0.2mm), cover the matching crucible cover, and then embed it into the sample tray of the needle penetration mode probe, then adjust the probe to contact with the center of the crucible cover, and set the temperature rise range 0- 70°C, the heating rate is 1°C / min, and the vibration frequency is 1Hz. After the initial temperature is balanced, start measuring and record the heating curve.

Embodiment 3

[0026] Cut a sample with a diameter of 8.0 mm and a height of 3.0 mm on a columnar or block-shaped PNIPAm nanocomposite hydrogel; place the sample to be tested in a self-made columnar flat-bottomed copper crucible, cover the matching crucible lid, and embed the needle together Put it into the sample tray of the mode probe, then adjust the probe to contact with the center of the crucible cover, set the temperature rise range 0-70°C, the temperature rise rate is 3°C / min, and the vibration frequency is 3.33Hz, and start measuring after the initial temperature is balanced And record the temperature rise curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com