Cationic polyester blended yarn with slub effect and production method thereof

A technology of cationic polyester and blended yarn, which is applied in yarn, textile and papermaking, etc. It can solve the problems of inconsistency in style and composition requirements, and achieve the effects of expanding product structure and scope, convenient management, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

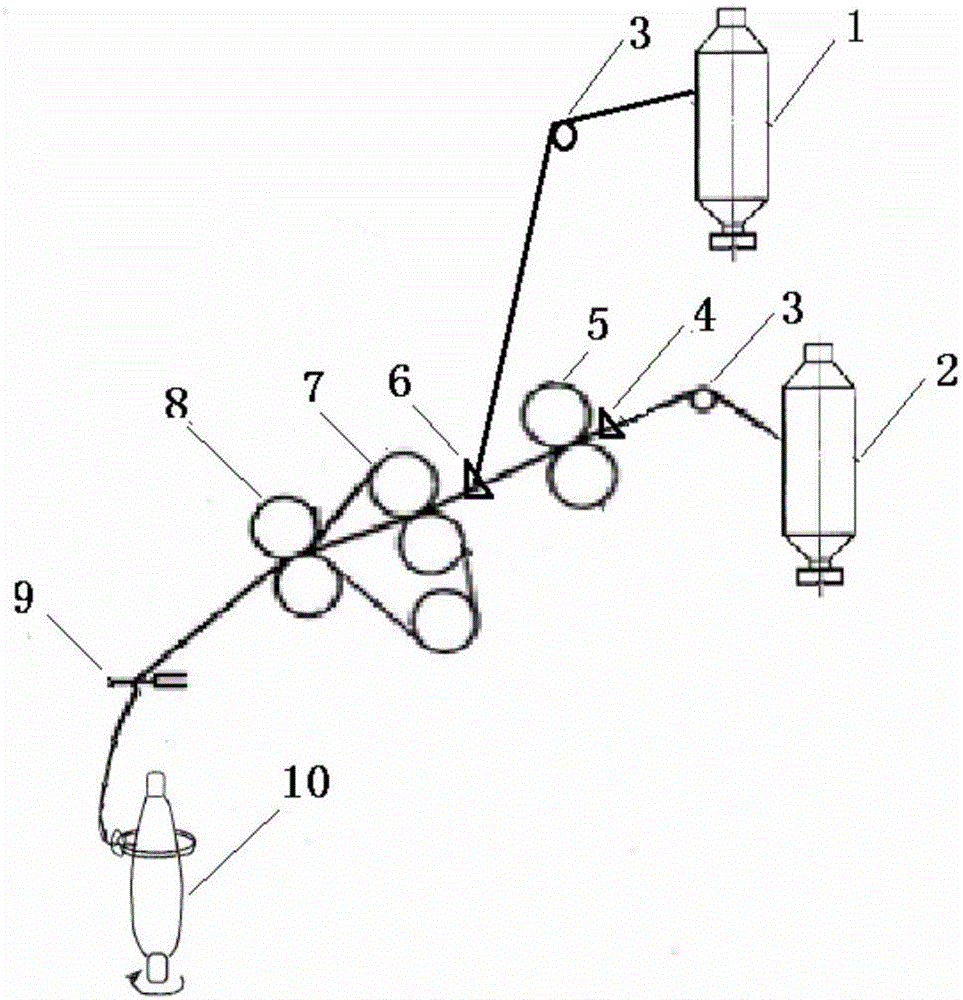

Method used

Image

Examples

Embodiment 1

[0048] Develop and produce a kind of segment color yarn whose composition is 60wt% cotton and 40wt% polyester, and the segment color style is short segments. After dyeing, the segment color effect is color dots, and the background color is white. The segment color process parameters are set in the following table:

[0049]

[0050] Calculated according to the above table, the content of auxiliary color roving in the finished yarn is 5.6wt%. According to the above calculation results, the auxiliary color roving composition is set to be 100wt% cationic polyester, the main color roving composition is 63.5wt% cotton and 36.5wt% ordinary polyester.

[0051] By adopting the above-mentioned process, the components of the obtained off-white segment colored yarn are 60wt% cotton and 40wt% polyester (wherein 5.6wt% is cationic polyester). The yarn obtained by the above method is used for weaving, and then Jingjiang Ruihua’s cationic black X-FBL is selected, and the dosage is 3wt% o...

Embodiment 2

[0053] Develop and produce a kind of segment color yarn whose composition is 60wt% viscose and 40wt% polyester, and the segment color style is medium segment. After dyeing, the segment color effect is color dots, and the background color is white. The segment color process parameters are set in the following table:

[0054]

[0055] Calculated according to the above table, the content of auxiliary color roving in the finished yarn is 12.7wt%. According to the above calculation results, the auxiliary color roving component is set to be 100wt% high temperature and high pressure cationic polyester, the main color roving component is 68.7wt% and the viscose is 31.7wt% ordinary polyester.

[0056] By adopting the above process, the composition of the off-white segment colored yarn is 60 viscose / 40 polyester (12.7 wt% of which is high temperature and high pressure cationic polyester). The yarn obtained by the above method is used for weaving, and then the cationic dye SD-O of Z...

Embodiment 3

[0058] Develop and produce a kind of segment color yarn whose composition is 60wt% cotton and 40wt% polyester, and the segment color style is long segment. After dyeing, the segment color effect is colored dots, and the background color is 5% dark light-colored yarn. The segment color process parameters are set in the following table:

[0059]

[0060] Calculated according to the above table, the content of auxiliary color roving in the finished yarn is 6.5wt%. According to the above calculation results, the auxiliary color roving component is set to be 100wt% cationic polyester. Because the base color requires 5% deep light color points, the main color roving composition is calculated to be 64.2wt% cotton, 30.8wt% ordinary polyester and 5% cationic polyester.

[0061] By adopting the above process, the components of the obtained off-white segment colored yarn are 60wt% cotton and 40wt% polyester (wherein 11.2wt% is cationic polyester). The yarn obtained by the above met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Twist | aaaaa | aaaaa |

| Twist | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com