Magnetic disk stirring pulse, sine wave gear disk pulse and magnetic drum pulse type electrolysis impurity removing tank

A technology of sine wave and electrolytic cell, which is applied in the fields of three-pulsation electrolytic miscellaneous tank of magnetic cylinder, sine wave gear plate, and disk stirring pulse, which can solve the problems of secondary pollution, ecological environment and human hazards, and achieve the promotion of high-efficiency electrolysis remove miscellaneous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with accompanying drawing, the present invention is described in further detail.

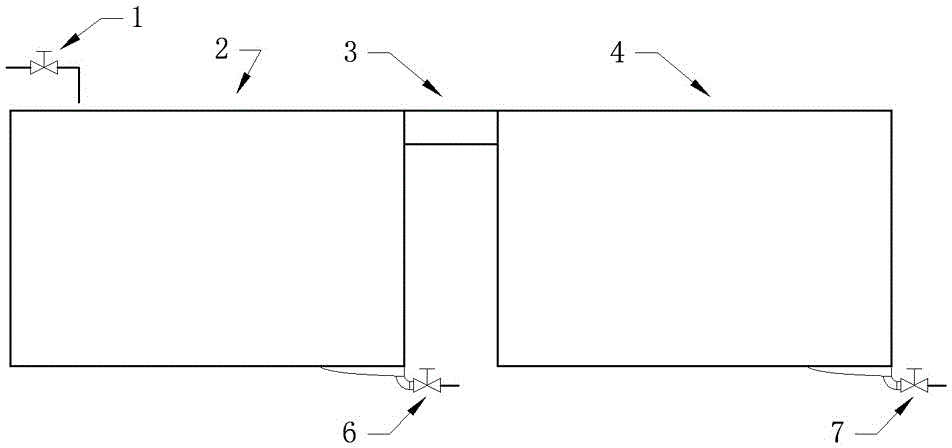

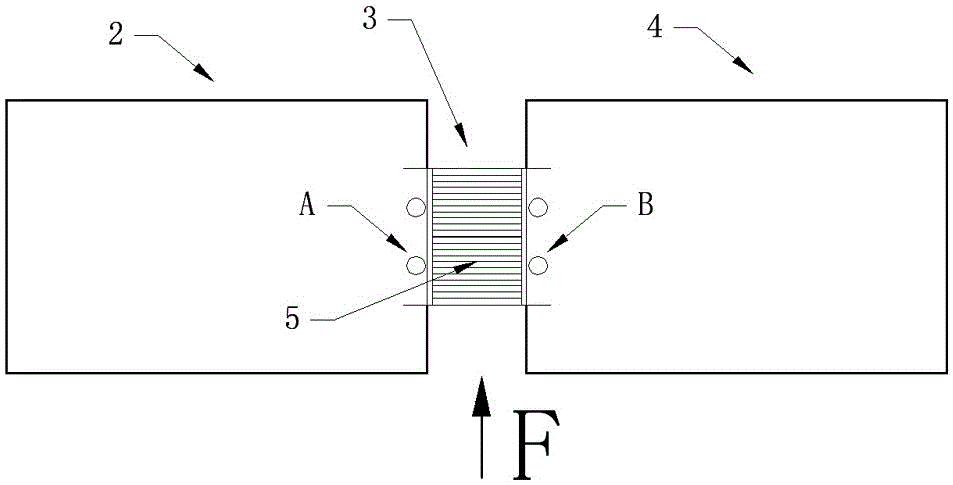

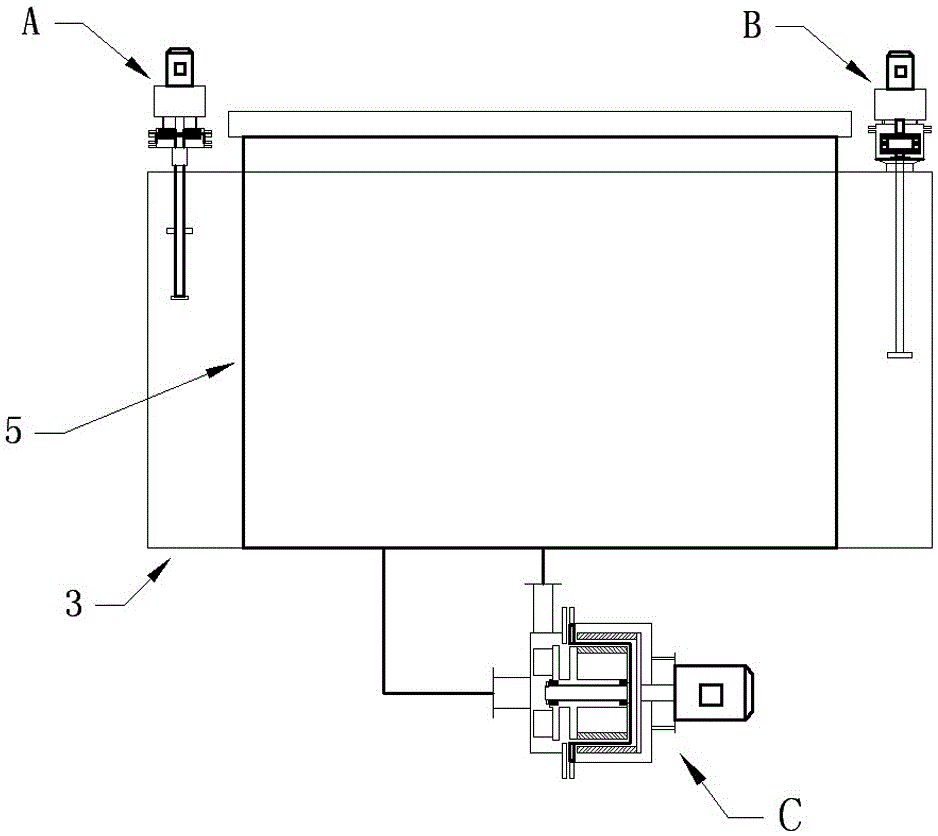

[0031] Such as Figure 1-7The shown disk stirring pulse, sine wave tooth disc, and magnetic cylinder three pulsating electrolytic impurity removal tanks, including electrolytic manganese compound press filtrate storage tank 2, impurity removal electrolytic tank 3 and electrolytic manganese qualified liquid storage tank 4, electrolytic manganese compound press filtrate storage tank The storage tank 2 is connected with the electrolytic manganese qualified liquid storage tank 4 through the impurity removal electrolytic tank 3, and the impurity removal electrolytic tank 3 is equipped with an electrolytic plate 5 with a stainless steel cathode and a lead alloy anode, a magnetic disk stirring pulser A and a sine wave gear plate Pulser B, the impurity removal electrolytic tank 3 is connected to the liquid inlet of the magnetic cylinder differential circulation pump through a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com