A method for pretreatment of lignocellulosic biomass

A lignocellulosic and biomass technology, applied in the field of biomass energy conversion and utilization, can solve the problems of restricting large-scale industrial application, difficulty in large-scale pretreatment equipment, narrow adaptability of raw materials, etc., and achieve the goal of being suitable for large-scale industrial application, Reduce equipment requirements and environmental pressure, taking into account the effect of energy consumption and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

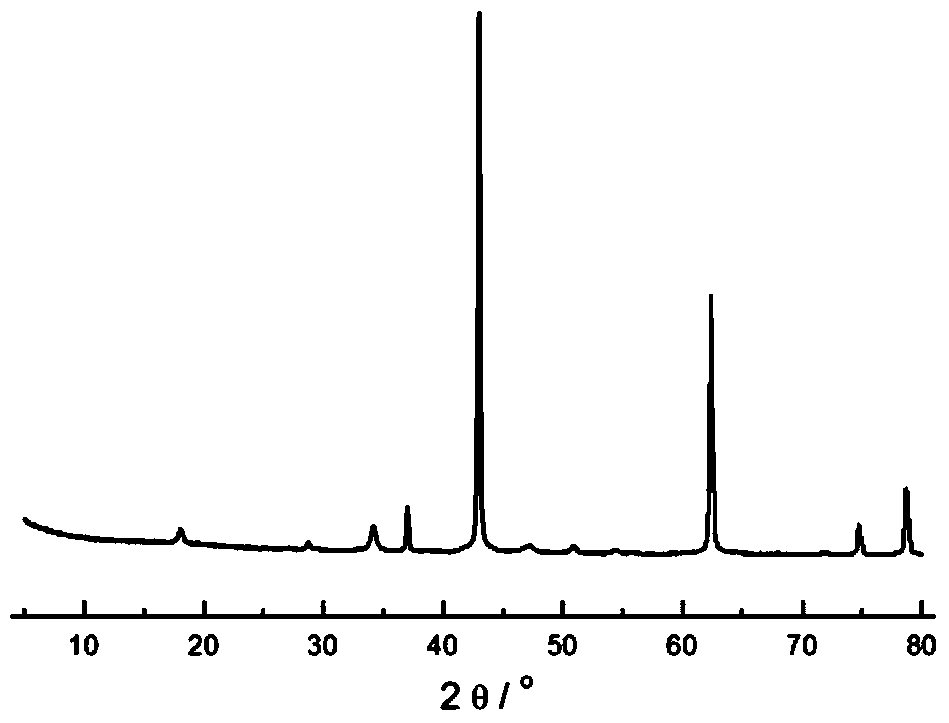

Image

Examples

Embodiment 1

[0021] Using pennisetum with a particle size of 0.5mm as the raw material, in the reactor, add the raw material, solid alkali catalyst and water at a mass ratio of 1:0.5:25, react at 150°C for 10 minutes, pass through a 80-mesh sieve, and collect the remaining The raw material slag on the sieve, the under-sieve is separated by solid-liquid again, and the solid obtained is a solid alkali catalyst; and the raw material slag collected after the pretreatment of the previous step is placed in the acetic acid / sodium acetate buffer solution with a pH value of 4.8, Add cellulase according to the dry weight of 40FPU / g raw material, enzymolyze at 50°C for 72h, and the enzymatic hydrolysis rate of cellulose is 86.3%.

Embodiment 2

[0027] Using pennisetum with a particle size of 2mm as the raw material, in the reactor, add the raw material, solid alkali catalyst and water at a mass ratio of 1:0.1:5, react at 80°C for 120 minutes, pass through a 80-mesh sieve, collect and leave in the sieve The raw material slag on the net, the under-sieve material is separated through solid-liquid again, and the solid obtained is a solid alkali catalyst; and the raw material slag collected after the previous step pretreatment is placed in the acetic acid / sodium acetate buffer solution with a pH value of 4.8, press 40FPU / g dry weight of raw material was added with cellulase, and enzymolysis was carried out at 50°C for 72 hours, and the enzymatic hydrolysis rate of cellulose was 67.1%.

Embodiment 3

[0029] Using pennisetum with a particle size of 0.5mm as the raw material, in the reactor, add the raw material, solid alkali catalyst and water at a mass ratio of 1:0.2:20, react at 110°C for 80 minutes, pass through an 80-mesh sieve, and collect the remaining The raw material slag on the sieve, the under-sieve is separated by solid-liquid again, and the solid obtained is a solid alkali catalyst; and the raw material slag collected after the pretreatment of the previous step is placed in the acetic acid / sodium acetate buffer solution with a pH value of 4.8, Add cellulase according to the dry weight of 40FPU / g raw material, enzymolyze at 50°C for 72h, and the enzymatic hydrolysis rate of cellulose is 92.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com