Aqueous UV wood paint, preparation method and application technology thereof

A water-based technology for wood coatings, applied in polyurea/polyurethane coatings, coatings, devices for coating liquids on surfaces, etc., can solve the problems of not being able to dry three-dimensional objects, large energy consumption of infrared drying, and affecting production efficiency , achieve good economic and social benefits, excellent adhesion, and improve environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

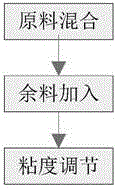

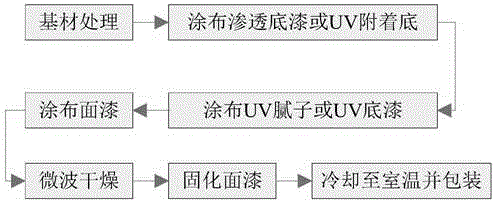

Method used

Image

Examples

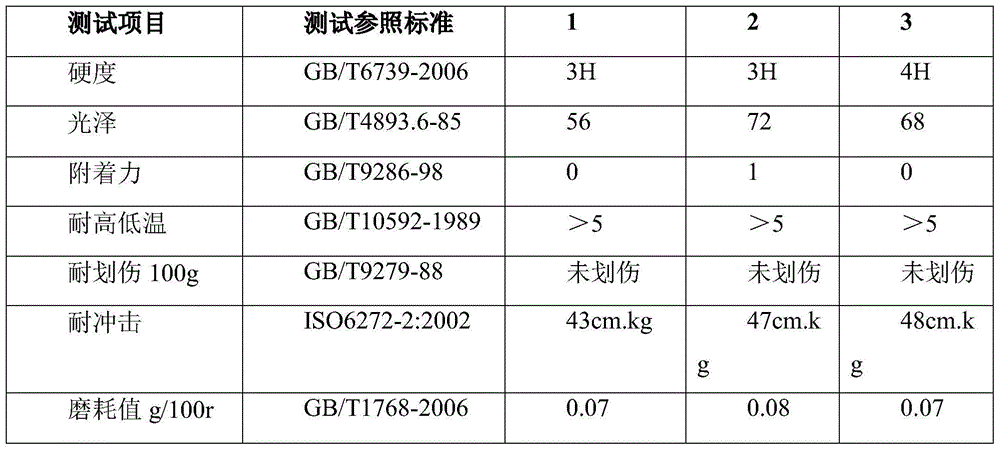

Embodiment 1

[0040] Example 1, the present invention includes 20% of water-based polyurethane resin, 60% of water-based UV resin, 0.6% of defoamer, 0.8% of leveling agent, 0.8% of wetting agent, 0.8% of thickener, 0.8% of initiator, dispersant 0.8%, 0.8% of matting powder, 16% of water, 0.6% of hand feeling additive, and the above-mentioned percentages are mass ratios. In this embodiment, the water-based UV resin is a macromolecular prepolymer, does not contain UV monomers, and has no solvent release during the construction process, and avoids the release of free UV monomers in the coating film from the coating surface, fundamentally ensuring It improves the environmental protection of water-based UV coatings, which is beneficial to the health of construction workers and environmental protection, and improves the environmental protection. In addition, the method of compounding high-hardness water-based UV resin and flexible water-based polyurethane combines the advantages of two different ...

Embodiment 2

[0041] Embodiment 2, the mass ratio of each component of the present invention is: water-based polyurethane resin 30%, water-based UV resin 40%, defoamer 0.5%, leveling agent 0.5%, wetting agent 0.5%, thickener 0.5%, initiator 0.5% agent, 0.5% dispersant, 0.5% matting powder, 26% water, 0.5% hand feeling additive.

Embodiment 3

[0042] Embodiment 3, the mass ratio of each component of the present invention is: water-based polyurethane resin 40%, water-based UV resin 20%, defoamer 0.2%, leveling agent 0.2%, wetting agent 0.2%, thickener 0.2%, initiator 0.2% agent, 0.2% dispersant, 0.2% matting powder, 32.4% water, 0.2% hand feeling aid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com