Novel hydrate dynamics inhibitor and application thereof

A kinetic inhibitor and hydrate technology, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of large influence of water content, large influence of supercooling, low inhibitory activity on polymerization inhibition performance, etc. Hydrate blockage, high degree of supercooling, and the effect of prolonging the formation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

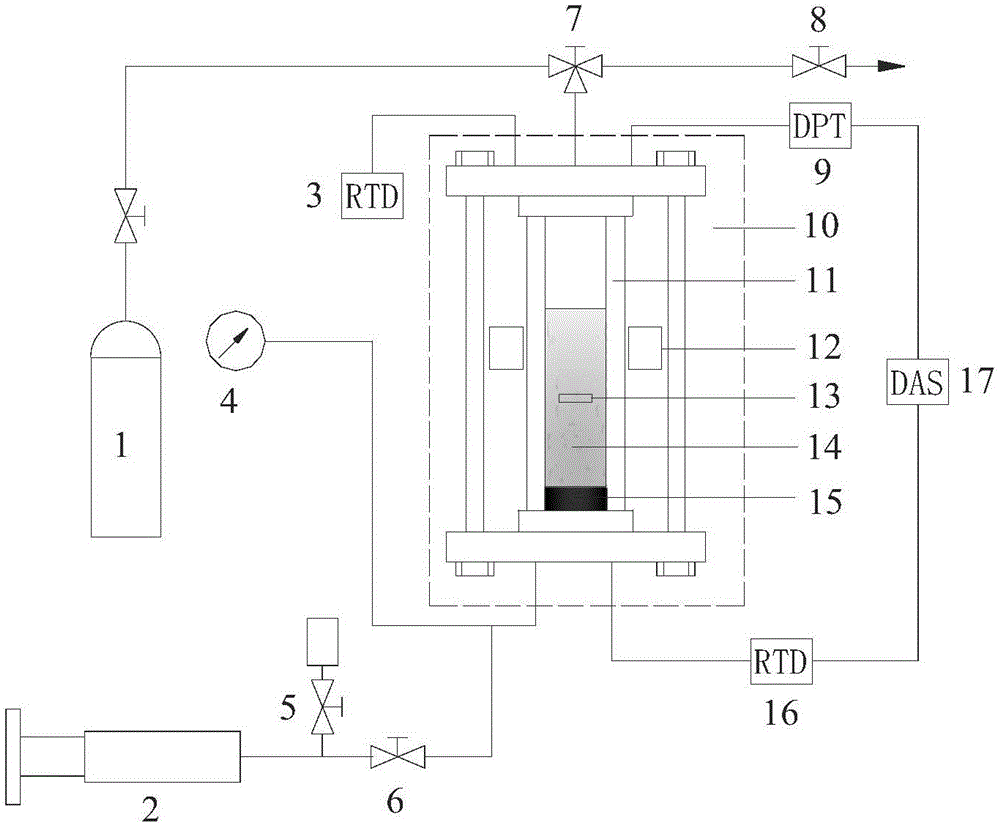

[0054] This example provides a novel hydrate kinetic inhibitor, which is obtained by mixing polyvinylcaprolactam, 4-acetylpyridine and ethanol at a mass ratio of 1:1:2.

[0055] In this example, the above-mentioned high-pressure fully transparent sapphire reactor is used for evaluation, and 15ml of deionized water is prepared, and the above-mentioned new hydrate kinetic inhibitor of 0.5% of the system water quality is added, the experimental pressure is 5.0MPa, and the experimental temperature is 277.2K , through the sapphire reactor, it was found that the time to inhibit hydrate nucleation was 987min, and the time to inhibit hydrate growth was 1440min.

Embodiment 2

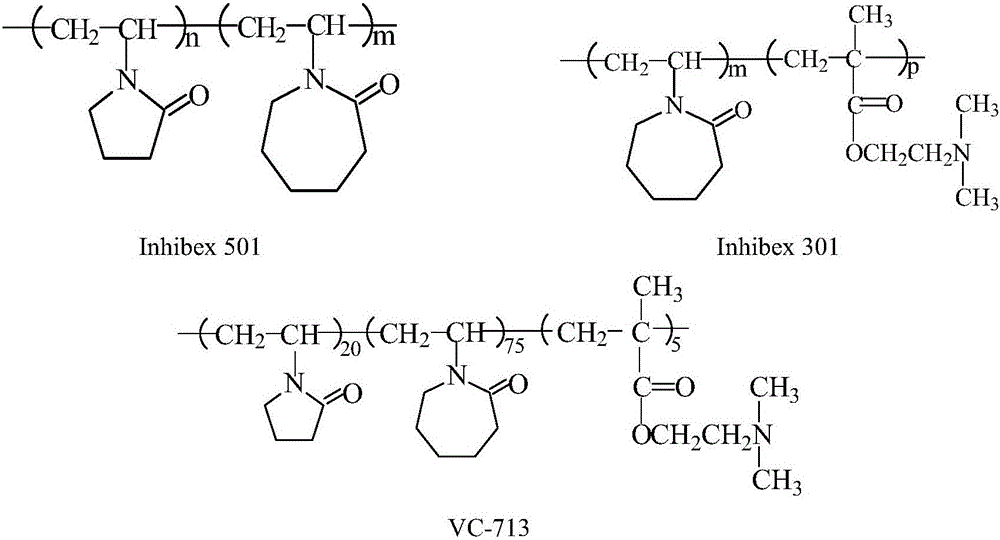

[0057] This example provides a new type of hydrate kinetic inhibitor, which is obtained by mixing Inhibex 501, 4-acetylpyridine and ethylene glycol at a mass ratio of 1:1:2.

[0058] In this example, the above-mentioned high-pressure fully transparent sapphire reactor is used for evaluation, and 15ml of deionized water is prepared, and the above-mentioned new hydrate kinetic inhibitor of 0.5% of the system water quality is added, the experimental pressure is 5.0MPa, and the experimental temperature is 277.2K , through the sapphire reactor, it was found that the time to inhibit the nucleation of hydrate was 987min, and the time to inhibit the growth of hydrate was more than 1440min.

Embodiment 3

[0060] This example provides a novel hydrate kinetic inhibitor, which is obtained by mixing VC-713, 5-acetyl-2-picoline and diethylene glycol monobutyl ether in a mass ratio of 2:1:1.

[0061] In this example, the above-mentioned high-pressure fully transparent sapphire reactor is used for evaluation, and 15ml of deionized water is prepared, and the above-mentioned new hydrate kinetic inhibitor of 1.0% of the system water quality is added, the experimental pressure is 5.0MPa, and the experimental temperature is 277.2K , found through the sapphire reactor, the time to inhibit hydrate nucleation is 1209min, and the time to inhibit hydrate growth is more than 1440min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com