Metal surface laser processing method in liquid medium

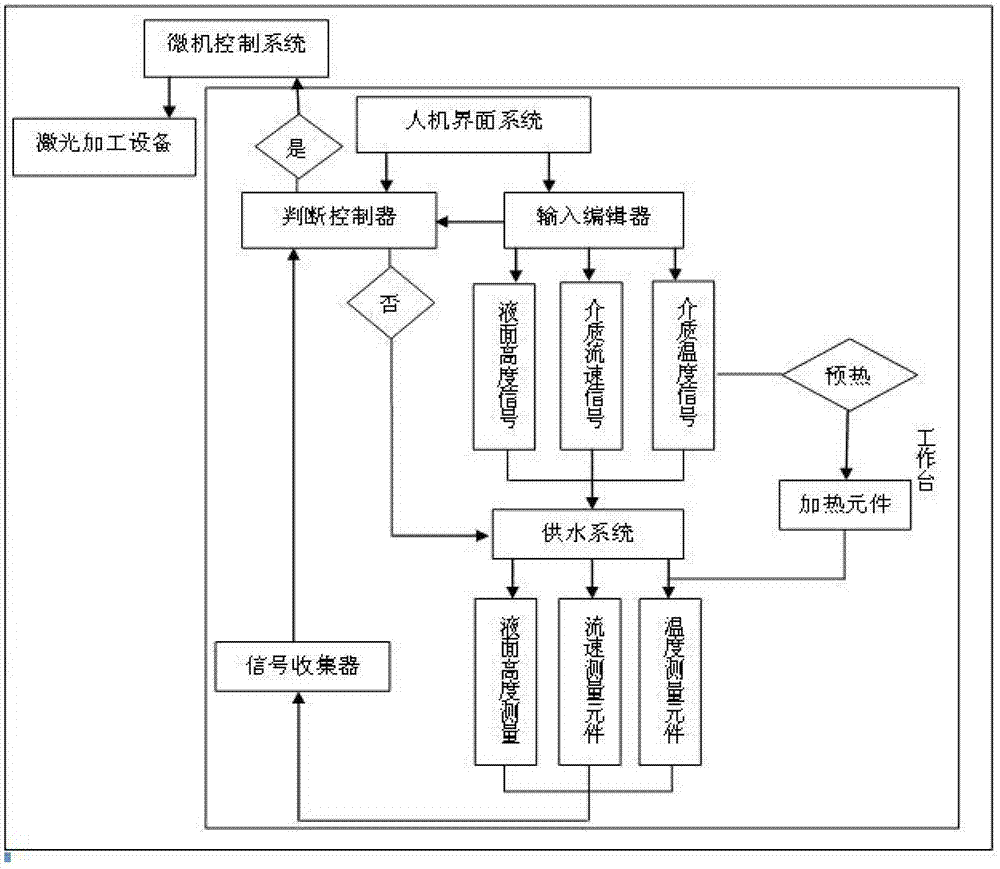

A laser processing method and liquid medium technology, applied in the field of advanced manufacturing, can solve problems such as drop, excessive thermal stress on the surface of materials, surface properties of cracked materials, etc., achieve excellent surface properties, fine structure in the treatment area, and improve component supercooling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

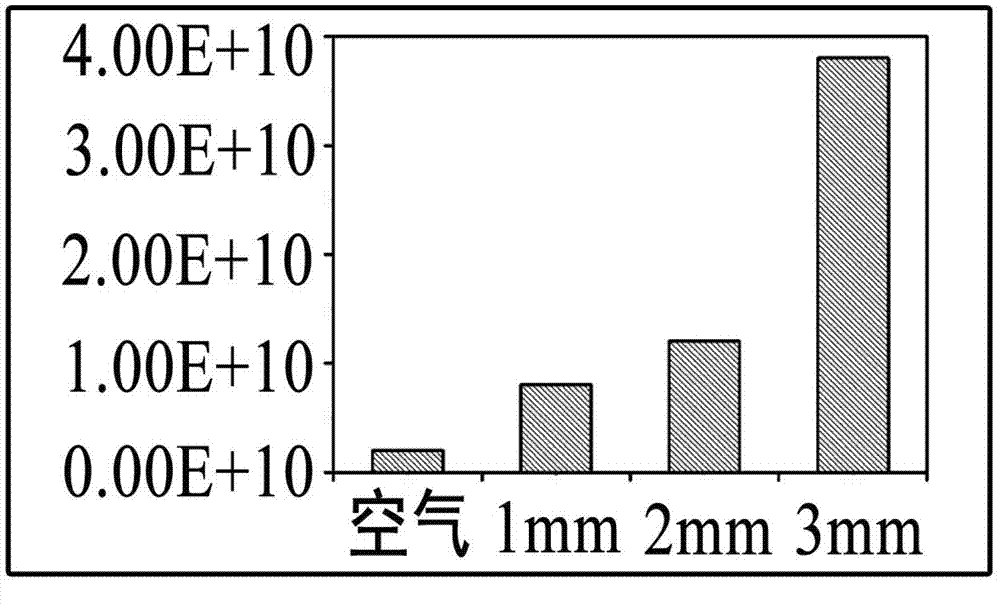

[0039] Example 1: Cooling speed of the laser treatment area of vermicular graphite cast iron with different water film thicknesses under air and still water medium.

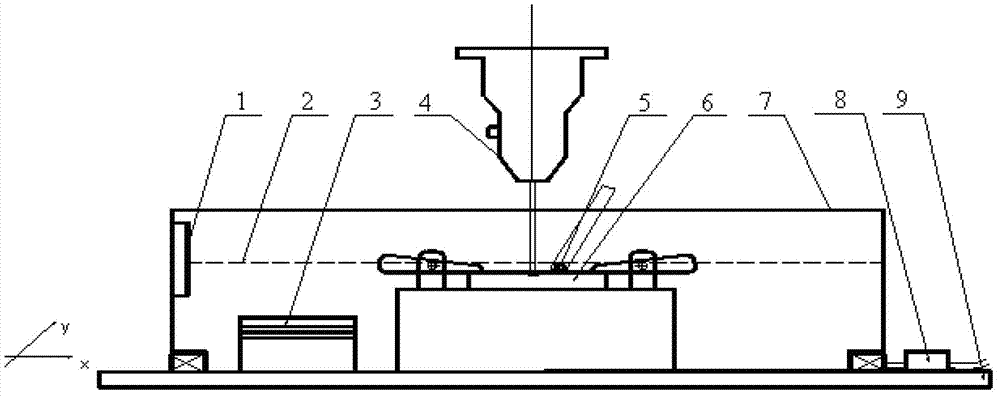

[0040] use figure 2 The components and procedures shown are used to prepare the laser surface under the water film medium, and the sample prepared under the air medium is selected as a reference sample. The material of the test piece is vermicular graphite cast iron, and the size of the test piece is 20×10×10mm 3 ; Laser parameters are: pulse frequency 3Hz, pulse width 5ms, laser single pulse energy 71J, spot diameter 0.7mm, defocus 5mm. The types of treatment specimens are: air medium treatment, 1mm, 2mm and 3mm water film medium treatment. The temperature of the aqueous medium was room temperature 25°C. Combined with the microstructure characteristics of the treatment area of each specimen processed under different conditions, the cooling rate of the treatment area under different processing media and m...

Embodiment 2

[0041] Example 2: Effects of laser treatment of GCr15 bearing steel with different water film thicknesses in air medium and flowing water medium.

[0042] use figure 2 The components and procedures shown are used to prepare the laser surface under the water film medium, and the sample prepared under the air medium is selected as a reference sample. The chemical composition (percentage) of the test piece GCr15 bearing steel is: C 0.95, Si 0.2, Mn 0.3, Cr 1.35, P3 ; The laser parameters are: the pulse frequency is 1Hz, the pulse width is 5ms, the input single pulse energy is 78J, the spot diameter is 0.7mm, and the defocus is 5mm. The thickness of the water film was set to 1 mm, 2 mm, and 3 mm respectively; the water flow rate was 0.5 mm / s; the temperature of the water medium was room temperature 25°C.

[0043] FEI XL-30FEG ESEM field emission scanning electron microscope was used to observe the surface morphology of the treated specimens a (1mm water film), b (2mm water film)...

Embodiment 3

[0045] Example 3: Friction and wear properties of laser-treated vermicular graphite cast iron surfaces with different water film thicknesses in air medium and static water medium.

[0046] use figure 2 The components and procedures shown are used to prepare the laser surface under the water film medium, and the sample prepared under the air medium is selected as a reference sample. The chemical composition (percentage) of the test piece vermicular graphite cast iron (CGI) is: C 3.56, Si 2.56, Mn 0.75, P0.03, S 0.03, Re 0.02, Mg 0.02. The standard specimen size of compacted graphite cast iron (CGI) is 20×10×10mm 3 ; The laser parameters are: the pulse frequency is 1Hz, the pulse width is 5ms, the input single pulse energy is 71J, the spot diameter is 0.7mm, and the defocus is 5mm. The thickness of the water film is 1mm, 2mm and 3mm respectively; the water film is in a static state; the temperature of the water medium is room temperature 25°C.

[0047] The friction and wear ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spot diameter | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com