Method and production system for preparing p-cresol by catalytic hydrolysis of p-toluidine

A technology for catalytic hydrolysis of p-toluidine, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as complicated process, low quality and purity, high temperature and high pressure equipment, and achieve simple reaction process, Improve environmental benefits and ensure safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

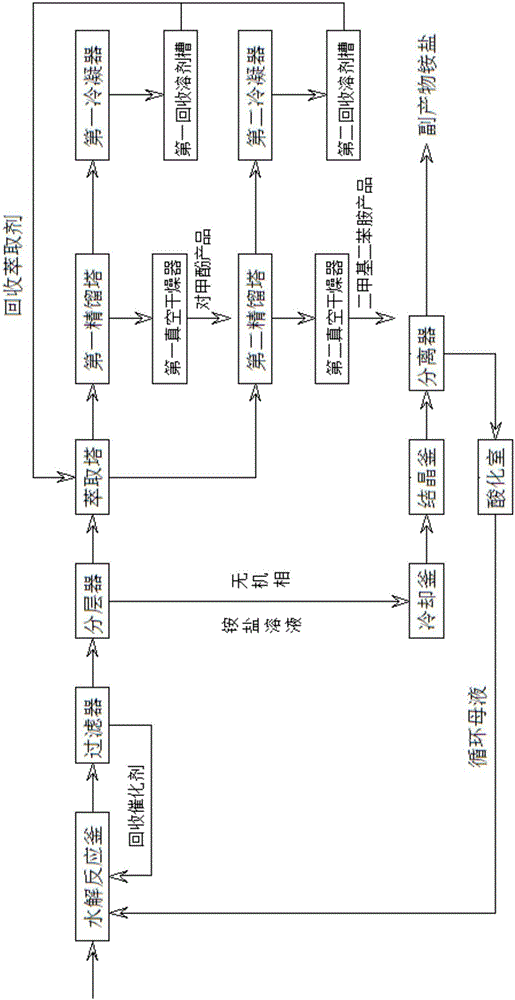

Image

Examples

Embodiment 1

[0044] Preparation of p-cresol by catalytic hydrolysis of p-toluidine

[0045]1) p-toluidine is hydrolyzed under catalyst and acidic conditions to obtain a hydrolyzed mixed solution.

[0046] 2) The hydrolyzed mixed solution obtained in step 1) is left to stand for stratification, and the organic phase is extracted and separated to obtain a crude p-cresol solution and a by-product 4,4'-dimethyldiphenylamine solution.

[0047] 3) The crude product p-cresol solution obtained in step 2) and the by-product 4,4'-dimethyldianiline solution are respectively rectified and dried successively to obtain the p-cresol product and 4,4'-dimethyldianiline crude product .

[0048] The pH value of hydrolysis is 5, provided by phosphoric acid, and the operating pressure of hydrolysis is 23kg / cm 2 , The hydrolysis operating temperature is 275°C, and the hydrolysis time is 12h.

[0049] The yield of p-cresol is 75.6%, and the purity is 99.85%.

Embodiment 2

[0051] Preparation of p-cresol by catalytic hydrolysis of p-toluidine

[0052] 1) p-toluidine is hydrolyzed under catalyst and acidic conditions to obtain a hydrolyzed mixed solution.

[0053] 2) The hydrolyzed mixed solution obtained in step 1) is left to stand for stratification, and the organic phase is extracted and separated to obtain a crude p-cresol solution and a by-product 4,4'-dimethyldiphenylamine solution.

[0054] 3) The crude product p-cresol solution obtained in step 2) and the by-product 4,4'-dimethyldianiline solution are respectively rectified and dried successively to obtain the p-cresol product and 4,4'-dimethyldianiline crude product .

[0055] The pH value of hydrolysis is 3, provided by sulfuric acid, and the operating pressure of hydrolysis is 32kg / cm 2 , The operating temperature of hydrolysis is 295°C, and the hydrolysis time is 10h.

[0056] The yield of p-cresol was 79.8%, and the purity was 99.75%.

Embodiment 3

[0058] Preparation of p-cresol by catalytic hydrolysis of p-toluidine

[0059] 1) p-toluidine is hydrolyzed under catalyst and acidic conditions to obtain a hydrolyzed mixed solution.

[0060] 2) The hydrolyzed mixed solution obtained in step 1) is left to stand for stratification, and the organic phase is extracted and separated to obtain a crude p-cresol solution and a by-product 4,4'-dimethyldiphenylamine solution.

[0061] 3) The crude product p-cresol solution obtained in step 2) and the by-product 4,4'-dimethyldianiline solution are respectively rectified and dried successively to obtain the p-cresol product and 4,4'-dimethyldianiline crude product .

[0062] The pH value of hydrolysis is 4, provided by phosphoric acid, and the operating pressure of hydrolysis is 26kg / cm 2 , the hydrolysis operating temperature is 287°C, and the hydrolysis time is 11h.

[0063] The yield of p-cresol was 77.1%, and the purity was 99.70%.

[0064] Through the method and system provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com