Device for extrusion moulding of fertilizer stick

An extrusion device and extrusion molding technology are applied in the direction of fertilization devices, fertilizer forms, fertilizer mixtures, etc., to achieve the effects of improving the pass rate, saving processing material costs, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

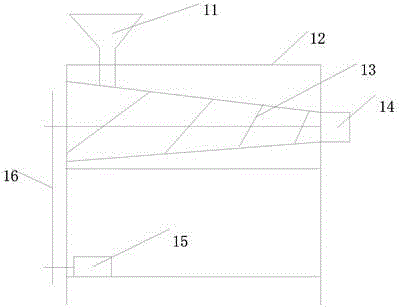

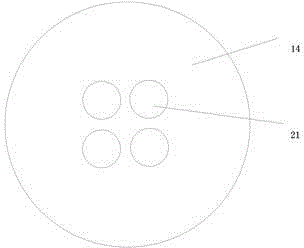

[0017] A kind of fertilizer bar extruding molding device, comprises feeding hopper 11, extruding device, forming discharge head cover 14, power unit 15 and frame 12, is characterized in that, described feeding hopper 11 is arranged on described extruding device The upper end away from the forming discharge head cover 14; the extruding device is composed of an extrusion chamber and a screw propeller 13 that is placed in the extrusion chamber and rotated and propelled by the power device; the forming discharge head cover 14 is a columnar hard Headgear, 15 centimeters long, is evenly provided with 4 columnar empty tubes 21 in the middle; The section shape of described columnar empty tubes 21 is circular, and the cross-sectional area of the discharge port is 10% smaller than the cross-sectional area of the feed port; The inner wall of the columnar empty tube 21 of the headgear 14 is coated with a layer of smooth nano-anti-sticking material; the formed discharge headgear 14 is s...

Embodiment 2

[0019] A kind of fertilizer bar extruding molding device, comprises feeding hopper 11, extruding device, forming discharge head cover 14, power unit 15 and frame 12, is characterized in that, described feeding hopper 11 is arranged on described extruding device The upper end away from the forming discharge head cover 14; the extruding device is composed of an extrusion chamber and a screw propeller 13 that is placed in the extrusion chamber and rotated and propelled by the power device; the forming discharge head cover 14 is a columnar hard Headgear, 10 centimeters long, is evenly provided with 4 columnar empty tubes 21 in the middle; The section shape of described columnar empty tubes 21 is quincunx, and the cross-sectional area of the discharge port is 5% smaller than the cross-sectional area of the feed port; The interior between the columnar hollow tube and the outer wall of the headgear 14 is a hollow structure, and the inner wall of the columnar hollow tube 21 is coat...

Embodiment 3

[0021] A kind of fertilizer bar extruding molding device, comprises feeding hopper 11, extruding device, forming discharge head cover 14, power unit 15 and frame 12, is characterized in that, described feeding hopper 11 is arranged on described extruding device The upper end away from the forming discharge head cover 14; the extruding device is composed of an extrusion chamber and a screw propeller 13 that is placed in the extrusion chamber and rotated and propelled by the power device; the forming discharge head cover 14 is a columnar hard Headgear, 10 centimeters long, is evenly provided with 4 columnar empty tubes 21 in the middle; The section shape of described columnar empty tubes 21 is quincunx, and the cross-sectional area of the discharge port is 5% smaller than the cross-sectional area of the feed port; The interior between the columnar hollow tube and the outer wall of the headgear 14 is a hollow structure, and the inner wall of the columnar hollow tube 21 is coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com