Emulsion gel based polyacrylonitrile/carbon porous material and preparation method thereof

A technology of carbon porous material and polyacrylonitrile, which is applied in the field of porous materials to achieve the effects of small density, easy large-scale production and practical application, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

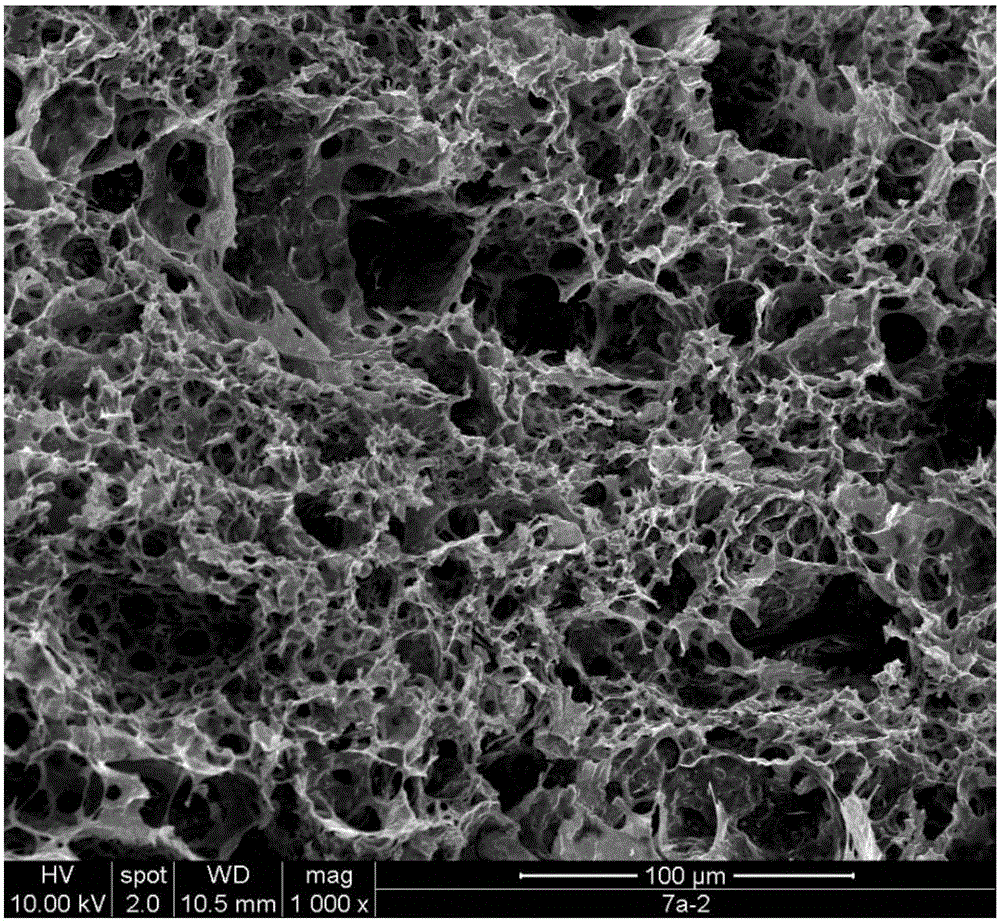

[0034]Dissolve 0.12g of polyacrylonitrile with a molecular weight of 80,000 in 2mL of 60% (mass concentration, the same below) zinc chloride solution under stirring at 70°C. After the polyacrylonitrile is completely dissolved, stop stirring and cool to room temperature , to obtain a polyacrylonitrile salt solution; add 0.12 g of acrylamide monomer, 5 mg of potassium persulfate, and 1.2 mg of N,N-methylenebisacrylamide to the solution in sequence, and disperse it evenly by ultrasonication. Then add 40 µL Tween-20, and add 8 mL of cyclohexane four times (2 mL each time), and emulsify by hand to prepare a homogeneous emulsion with an oil-water ratio of 4:1. The emulsion was polymerized in an oil bath at 70° C. for 12 hours to obtain an emulsion gel. The emulsion gel was taken out from the glass bottle, soaked in 1L of deionized water for 36 hours, frozen in the refrigerator, and then placed in a freeze dryer for 48 hours to freeze-dry to obtain a polyacrylonitrile porous material...

Embodiment 2

[0036] Dissolve 0.12g of polyacrylonitrile with a molecular weight of 80,000 in 2mL of 60% zinc chloride solution under stirring at 70°C. After the polyacrylonitrile is completely dissolved, stop stirring and cool to room temperature to obtain a polyacrylonitrile salt solution. ; Add 0.16g of acrylamide monomer, 6mg of ammonium persulfate, and 2.4mg of N,N-methylenebisacrylamide to the solution in sequence, and disperse it evenly by ultrasonication. Then add 40 µL Tween-40, and add 6 mL of cyclohexane three times (2 mL each time), and emulsify by hand to prepare a homogeneous emulsion with an oil-water ratio of 3:1. The emulsion was polymerized in an oil bath at 65° C. for 18 hours to obtain an emulsion gel. The emulsion gel was taken out from the glass bottle, soaked in 1L of deionized water for 36 hours, frozen in the refrigerator, and then placed in a freeze dryer for 48 hours to freeze-dry to obtain a polyacrylonitrile porous material. The polyacrylonitrile porous materia...

Embodiment 3

[0038] Dissolve 0.16g of polyacrylonitrile with a molecular weight of 70,000 in 2mL of 50% sodium thiocyanate solution under stirring at 70°C. After the polyacrylonitrile is completely dissolved, stop stirring and cool to room temperature to obtain polyacrylonitrile salt Solution; add 0.12g of acrylamide monomer, 5mg of potassium persulfate, 1.2mg of N,N-methylenebisacrylamide, and 0.04g of hydrophilic silica particles to the solution in sequence, and disperse it evenly by ultrasonication. Then add 8 mL of benzene four times (2 mL each time), and emulsify by hand to prepare a homogeneous emulsion with an oil-water ratio of 4:1. The emulsion was polymerized in an oil bath at 70° C. for 12 hours to obtain an emulsion gel. The emulsion gel was taken out from the glass bottle, soaked in 1 L of deionized water for 48 hours, frozen in liquid nitrogen, and then placed in a freeze dryer for 48 hours to freeze-dry to obtain a polyacrylonitrile porous material. The polyacrylonitrile po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com