Low-pressure casting segmented mold and method for casing aluminum alloy pattern ring through low-pressure casting segmented mold

A low-pressure casting and flexible mold technology, which is applied in the field of tire mold aluminum pattern ring manufacturing, can solve the problems of unstable product quality, poor fatigue resistance, poor casting performance, etc., achieve accurate shrinkage parameters, improve processing accuracy, and control dimensions Effects of errors and form errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be noted that these implementation examples are not used to limit the scope of the present invention.

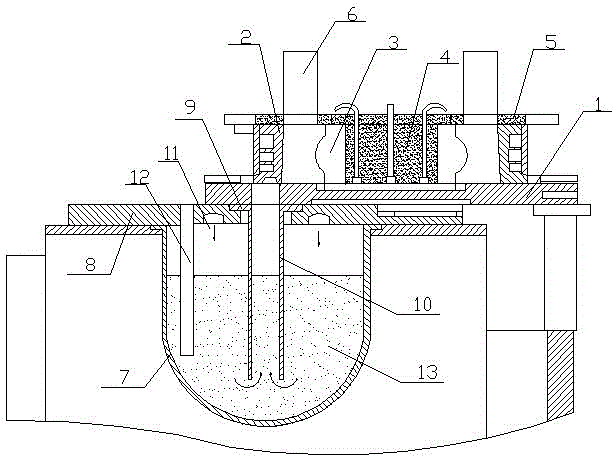

[0031] Such as figure 1 As shown, the low-pressure casting active mold of the present invention, the low-pressure casting active mold includes a lower cover plate 1, a casting mold 2 arranged on the lower cover plate 1, a gypsum core 3 and a mold core arranged in the casting mold 2 4. The upper end of the casting mold 2 is provided with an upper cover plate 5, and the upper cover plate 5 is provided with a soup pressure pipe 6, which communicates with the gypsum core 3, and the lower cover plate 6 is provided with a melting furnace 7 A support plate 8 and a base plate 9 nested in the groove of the support plate 8 are arranged between the lower cover plate 6 and the melting furnace 7, the base plate 9 is provided with a liquid riser 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com