Maize straw charcoal, method for utilizing maize straw charcoal to remove triclosan from water and application

A corn stalk and biochar technology is applied in chemical instruments and methods, water pollutants, and other chemical processes to achieve the effect of ensuring the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of corn stalk biochar, it is prepared through the following steps:

[0036] (1) Wash the corn stalks with tap water, air-dry them naturally, cut them into 1-5cm pieces, pulverize them with a grinder, mix them well, and seal them;

[0037] (2) Put the crushed corn stalks in the tubular atmosphere furnace and check the tightness;

[0038] (3) Use nitrogen to remove the oxygen in the tube of the tube atmosphere furnace, then open the tube atmosphere furnace, feed nitrogen, the nitrogen pressure is 0.25MPa, the outlet pipe is sealed with water to ensure air tightness, and the whole process is kept in the furnace tube anaerobic state;

[0039] (4) Program controlled temperature rise, rising to 450°C at 15°C / min, keeping for 20 minutes, rising to 700°C at the same heating rate, keeping for 180 minutes, and cooling to 500°C at 20°C / min;

[0040] (5) Cool to room temperature in the furnace to obtain biochar;

[0041] (6) Soak biochar in 1mol / L hydrochloric acid for 12...

Embodiment 2

[0044] Using the corn stalk biochar obtained in Example 1 as an adsorbent to treat polluted water containing triclosan, the dosage of the adsorbent is 4g / L, at 25°C, neutral, the initial concentration of triclosan is 10mg / L, After 90 minutes of reaction, the removal rate of triclosan reached 98.28%, and the biochar loading reached 2.717mg / L.

Embodiment 3

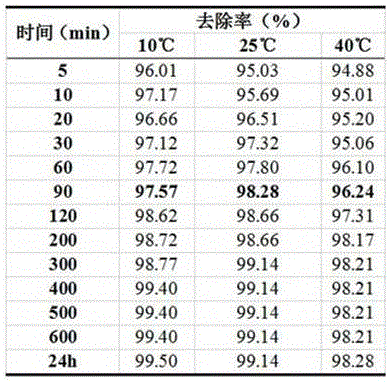

[0046] Using the corn stalk biochar obtained in Example 1 as an adsorbent to treat polluted water containing triclosan, the dosage of the adsorbent is 4g / L, neutral, and the initial concentration of triclosan is 10mg / L. The effect on the removal rate is shown in Table 1.

[0047] Table 1 The influence of time and temperature on the removal rate.

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com