Method for purifying nitrogen-containing oxide tail gas

A technology of nitrogen oxides and tail gas, which is applied in the field of nitrogen oxides and purification of tail gas containing nitrogen oxides. It can solve the problems of not considering the effect of denitrification, not seeing a high-gravity device, reducing the efficiency of NOx purification, etc., and achieving hysteresis Effects of phase separation, improved stability, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] The tail gas volume of a catalyst production unit is 2000Nm 3 / h, the exhaust gas temperature is 450°C, and the maximum NOx content is 52700mg / m3 , O 2 The concentration is 1.8%, and as the production proceeds, the NOx concentration gradually decreases by 480mg / m 3 , O 2 The concentration was increased to 6.2%.

[0086] The whole tail gas treatment system is composed of denitration solution circulation unit, denitration solution cooling unit, tail gas distribution and delivery unit, reaction and gas-liquid separation unit.

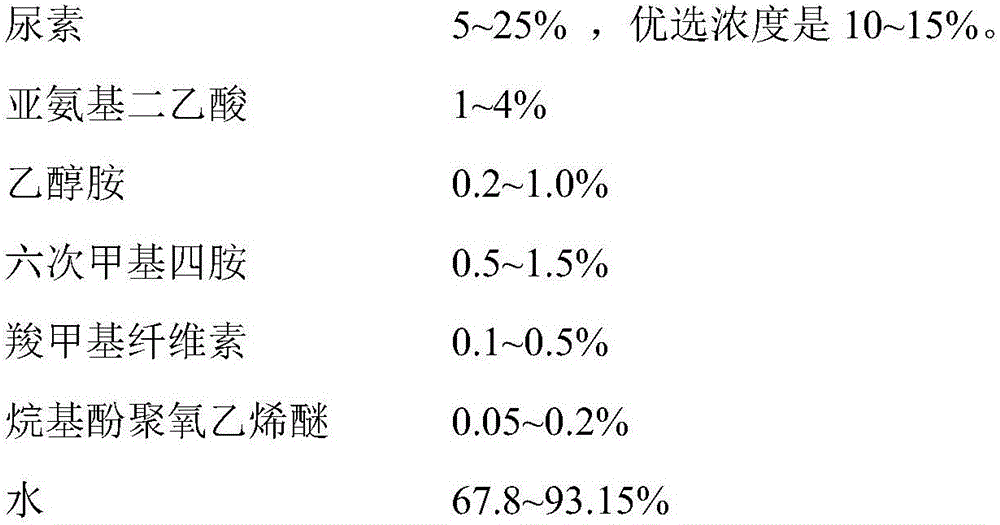

[0087] The denitration solution circulation unit is composed of a denitration solution preparation tank, a circulating mother liquor storage tank, and a pump. The composition of the denitration solution is 2.0% of iminodiacetic acid, 0.5% of diethanolamine, 1.0% of urotropine, 0.3% of carboxymethyl cellulose, 0.1% of nonylphenol polyoxyethylene ether, 15% of urea, and the balance is water.

[0088] The denitrification solution cooling unit is co...

Embodiment 2

[0093] Different from Example 1, the composition and percentage of the denitrification solution are:

[0094] Iminodiacetic acid 3.5%, monoethanolamine 1.0%, urotropine 1.5%, carboxymethyl cellulose 0.4%, nonylphenol polyoxyethylene ether 0.15%, urea 25%, and the balance is water.

[0095] The NOx concentration in the tail gas at the outlet of the liquid separator is 17mg / m 3 .

Embodiment 3

[0097] The difference with embodiment 1 is:

[0098] The residence time of the liquid in the cyclone is 36 seconds, the frequency of the ultrasonic transducer is 50kHz, and the ultrasonic power is 3000W.

[0099] The NOx concentration in the tail gas at the outlet of the liquid separator is 22mg / m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com