Method for coating diamond-like film on the surface of zinc sulfide substrate and zinc sulfide plate with diamond-like film

A diamond-like film and zinc sulfide technology, applied in gaseous chemical plating, sputtering plating, vacuum evaporation plating, etc., can solve the problems of film release, poor uniformity of film stress distribution, etc., and achieve the effect of preventing DLC film from falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

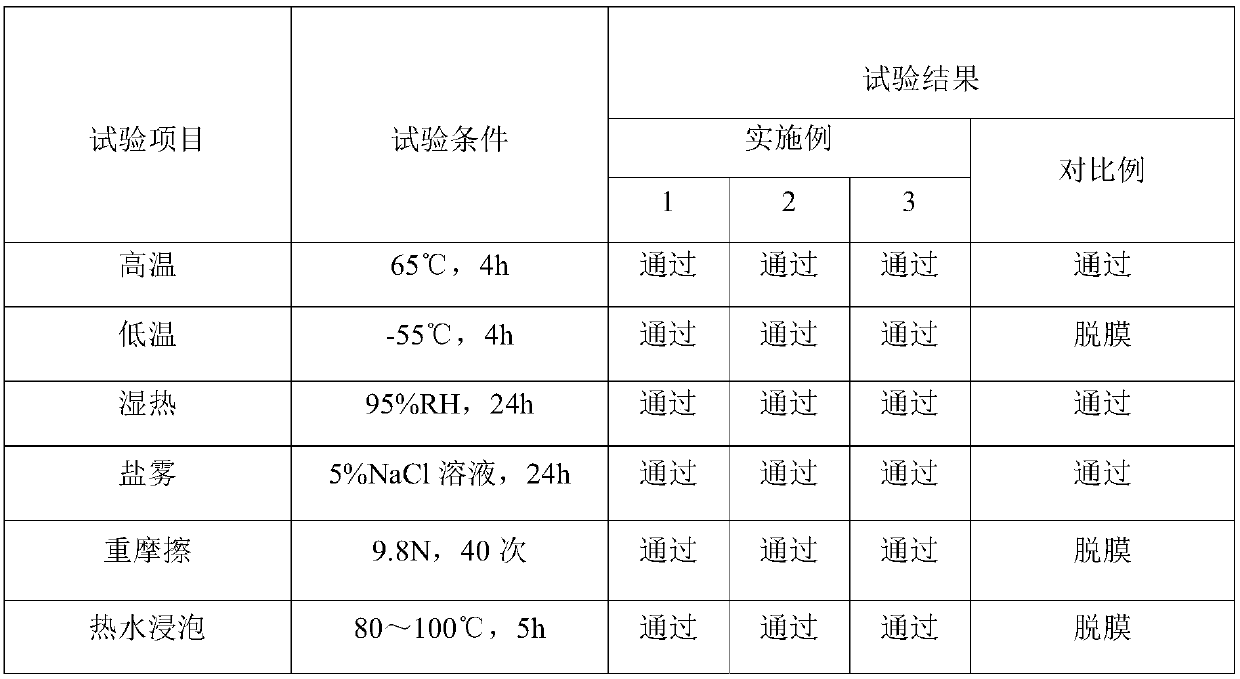

Examples

Embodiment 1

[0034] Step 1: Clean the substrate

[0035] The zinc sulfide circular plate with a diameter of 200mm is carefully wiped clean with absorbent cotton dripped with a mixture of petroleum ether and alcohol before coating, and then ultrasonically cleaned in acetone for 15 minutes. Oven dry, set aside.

[0036] Step 2: Overcoating and plating

[0037] Put the cleaned zinc sulfide circular plate into the electron beam evaporation coating machine to coat the optical anti-reflection coating. The Ge film is used as the innermost layer of the anti-reflection coating system and also serves as a transition layer, with a thickness of 60nm. After the plating is completed, take out the zinc sulfide circular plate. The plating parameters are: bake at 100°C for 40 minutes, argon auxiliary anode at 300V, 1A.

[0038] Step 3: Surface Segmentation

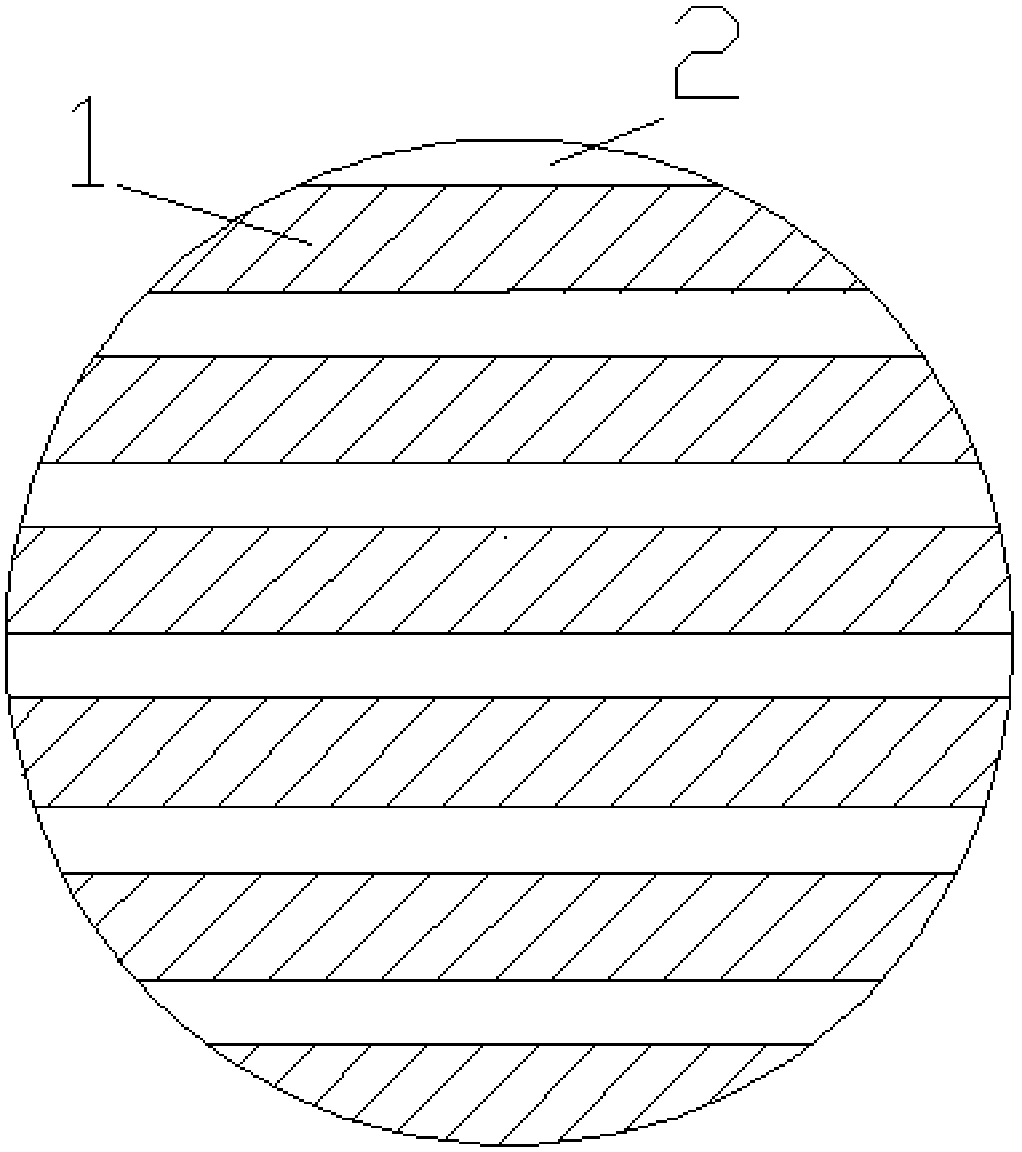

[0039] figure 1 is a schematic diagram of the structure of the first grid mask, such as figure 1 As shown, the first grid cover includes a metal ...

Embodiment 2

[0047] Step 1: Clean the substrate

[0048] The zinc sulfide circular plate with a diameter of 250mm is carefully wiped clean with absorbent cotton dripped with a mixture of petroleum ether and alcohol before coating, and then ultrasonically cleaned in acetone for 15 minutes. Oven dry, set aside.

[0049] Step 2: Transition layer coating

[0050] Put the cleaned zinc sulfide circular plate into the electron beam evaporation coating machine to coat the optical anti-reflection coating. The Ge film is used as the innermost layer of the anti-reflection coating system and also serves as a transition layer, with a thickness of 60nm. After the plating is completed, take out the zinc sulfide circular plate, bake at 80°C for 60 minutes, and argon assist the anode at 310V, 1.1A.

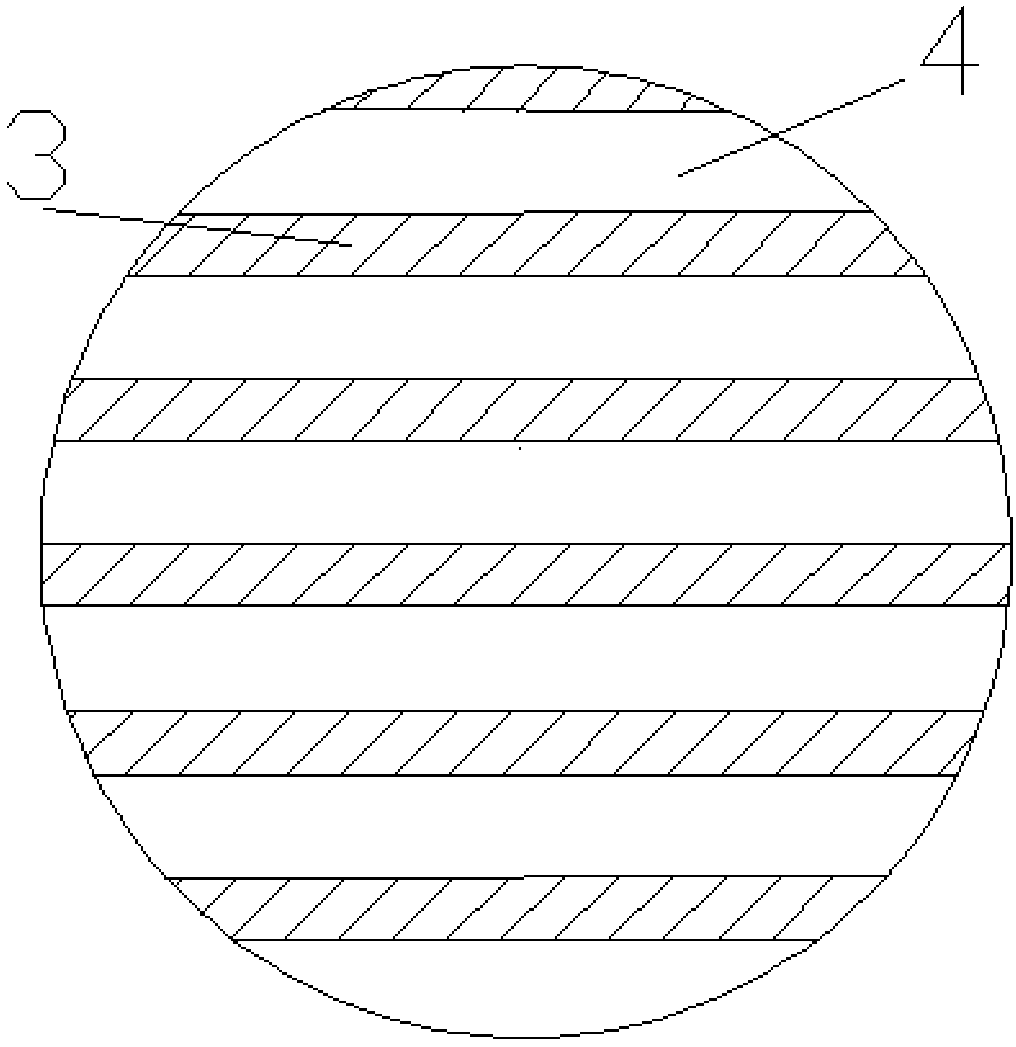

[0051] Step 3: Surface Segmentation

[0052] When dividing the surface of the zinc sulfide substrate, first use a 10mm wide high-temperature adhesive tape to divide the zinc sulfide circular plate substrate...

Embodiment 3

[0059] Step 1: Clean the substrate

[0060] The square zinc sulfide plate with a side length of 10cm is carefully wiped clean with absorbent cotton dripped with a mixture of petroleum ether and alcohol before coating, and then ultrasonically cleaned in acetone for 15 minutes. After taking it out, dry the substrate with absorbent cotton, and finally wipe it with alcohol. Oven dry, set aside.

[0061] Step 2: Transition layer coating

[0062] Put the cleaned zinc sulfide circular plate into the electron beam evaporation coating machine to coat the optical anti-reflection coating. The Ge film is used as the innermost layer of the anti-reflection coating system and also serves as a transition layer, with a thickness of 60nm. After the plating is completed, take out the zinc sulfide circular plate. The plating parameters are: bake at 120°C for 30 minutes, argon assisted anode at 290V, 0.9A.

[0063] Step 3: Surface Segmentation

[0064] When dividing the surface of the zinc sulf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com