6042 aluminum alloy and preparation method thereof

A technology of aluminum alloy and molten aluminum, applied in the field of metallurgy, can solve the problems of inability to meet customer gloss requirements, long time for smelting aluminum alloy, and compression of profit margins of enterprises, so as to shorten the melting time, shorten the melting time, and improve the appearance quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

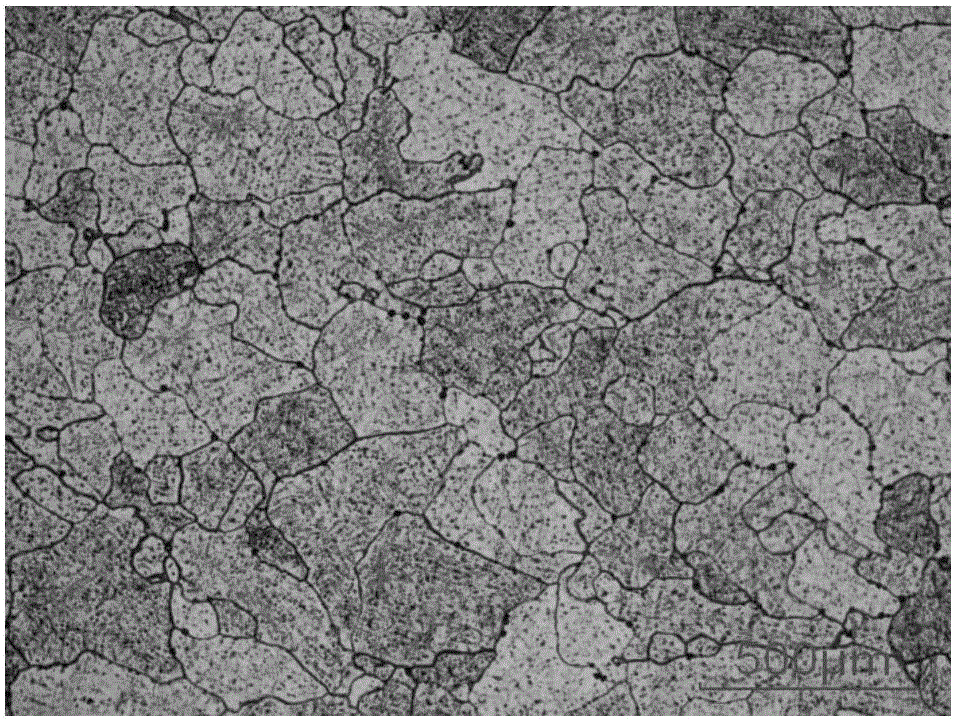

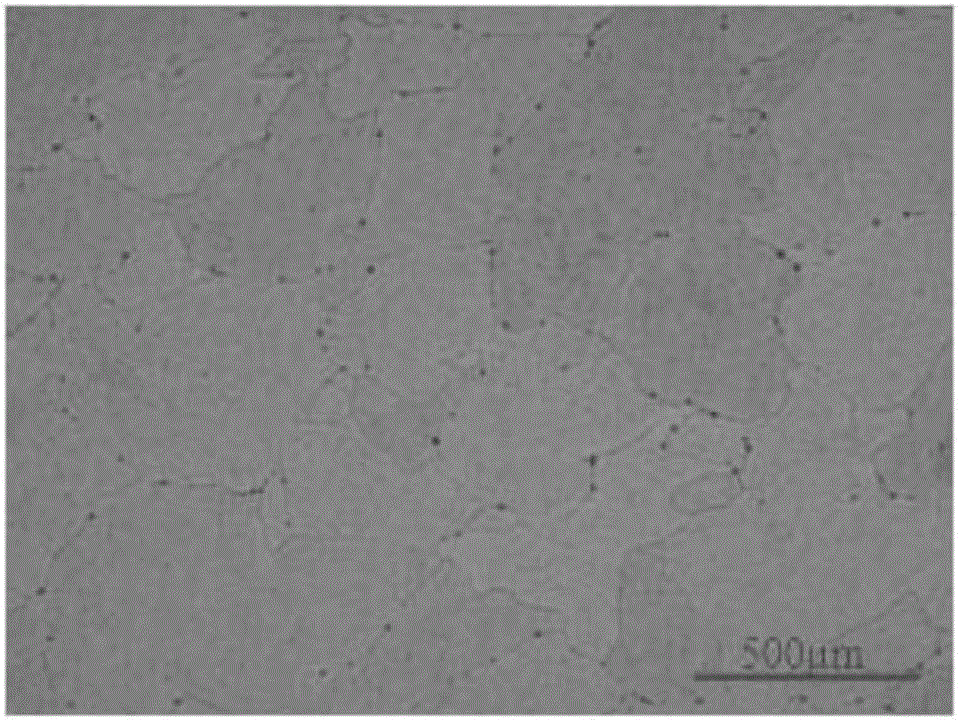

Image

Examples

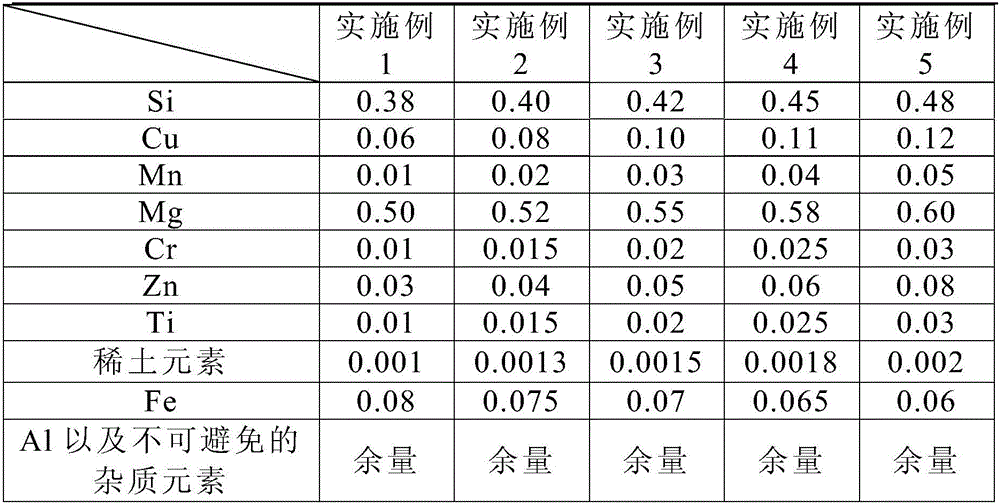

Embodiment 1

[0037] According to the composition and mass percentage of the 6042 aluminum alloy of Example 1 in Table 1, the weight ratio is (2-3): 1 99.99% high-purity refined aluminum ingot and Fe content of 0.05-0.15% Fe-containing Aluminum ingots are placed in an aluminum smelting furnace and heated to 730-740°C to melt into aluminum liquid, and then added aluminum-silicon master alloy, aluminum-copper master alloy, aluminum-zinc alloy, manganese-aluminum master alloy, chromium alloy and titanium alloy, Si, Cu, The addition amount of Mn, Cr, Zn, Ti element is 70-85% of target value. Then add refining agent to the molten alloy in the smelting furnace for refining, and carry out slag removal treatment.

[0038] After the slag removal treatment, add the remaining aluminum-silicon master alloy, aluminum-copper master alloy, aluminum-zinc alloy, manganese-aluminum master alloy and chromium alloy into the molten aluminum in the smelting furnace according to the set required content, and then...

Embodiment 2

[0043] According to the composition and mass percentage of the 6042 aluminum alloy of Example 2 in Table 1, the weight ratio is (2-3): 1 99.99% high-purity refined aluminum ingot and Fe content of 0.05-0.15% Fe-containing Aluminum ingots are placed in an aluminum smelting furnace and heated to 730-740°C to melt into aluminum liquid, and then added aluminum-silicon master alloy, aluminum-copper master alloy, aluminum-zinc alloy, manganese-aluminum master alloy, chromium alloy and titanium alloy, Si, Cu, The addition amount of Mn, Cr, Zn, Ti element is 70-85% of target value. Then add refining agent to the molten alloy in the smelting furnace for refining, and carry out slag removal treatment.

[0044] After the slag removal treatment, add the remaining aluminum-silicon master alloy, aluminum-copper master alloy, aluminum-zinc alloy, manganese-aluminum master alloy and chromium alloy into the molten aluminum in the smelting furnace according to the set required content, and then...

Embodiment 3

[0049] According to the composition and mass percentage of the 6042 aluminum alloy of Example 3 in Table 1, the weight ratio is (2-3): 1 99.99% high-purity refined aluminum ingot and Fe content of 0.05-0.15% Fe-containing Aluminum ingots are placed in an aluminum smelting furnace and heated to 730-740°C to melt into aluminum liquid, and then added aluminum-silicon master alloy, aluminum-copper master alloy, aluminum-zinc alloy, manganese-aluminum master alloy, chromium alloy and titanium alloy, Si, Cu, The addition amount of Mn, Cr, Zn, Ti element is 70-85% of target value. Then add refining agent to the molten alloy in the smelting furnace for refining, and carry out slag removal treatment.

[0050] After the slag removal treatment, add the remaining aluminum-silicon master alloy, aluminum-copper master alloy, aluminum-zinc alloy, manganese-aluminum master alloy and chromium alloy into the molten aluminum in the smelting furnace according to the set required content, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com