A kind of graphene/nickel-based composite material and preparation method thereof

A composite material and graphene technology, which is applied in the field of graphene-enhanced nickel-based composite materials and its preparation, can solve the problems of graphene-enhanced nickel-based composite materials that have not yet been seen, and achieve the effect of preventing material oxidation, avoiding agglomeration, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The basic operation steps of present embodiment 1 preparation graphene / copper composite material are as follows:

[0040] Ⅰ) Material composition of graphene / nickel composites

[0041]The material components of the graphene / copper composite material are mainly metal nickel and graphene, wherein the mass fraction of nickel is 99.5wt%; the mass fraction of graphene is 0.5wt%. The raw material of graphene is graphene oxide.

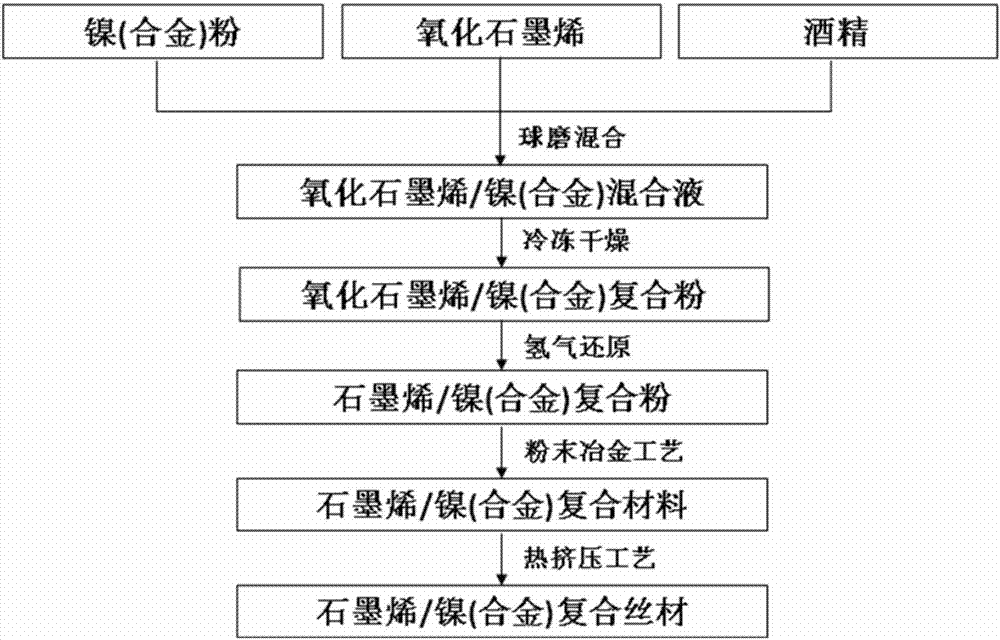

[0042] Ⅱ) Basic steps for preparing graphene / nickel composites (see attached figure 1 )

[0043] 1) taking by weighing 50g of copper-nickel alloy powder and 20ml concentration is the graphene oxide dispersion of 0.015g / ml;

[0044] 2) According to the ball-to-material ratio of 15:1, put grinding balls, nickel powder, graphene oxide dispersion liquid and alcohol into a ball mill tank, and ball mill for 5 hours. As the ball milling progresses, the nickel powder and graphene oxide are fully mixed to obtain a graphene oxide / nickel alcohol mixture.

...

Embodiment 2

[0050] The difference from Example 1 is that: this Example 2 adds a hot extrusion process to obtain a graphene / nickel composite wire.

[0051] The basic operation steps of present embodiment 2 preparation graphene / copper composite material are as follows:

[0052] Ⅰ) Material composition of graphene / nickel composites

[0053] The material components of the graphene / copper composite material are mainly metallic nickel and graphene, wherein the raw materials and contents of metallic nickel and graphene are the same as those in Example 1.

[0054] Ⅱ) Basic steps for preparing graphene / nickel composites (see attached figure 1 )

[0055] 1) taking by weighing 50g of copper-nickel alloy powder and 20ml concentration is the graphene oxide dispersion of 0.015g / ml;

[0056] 2) According to the ball-to-material ratio of 15:1, put grinding balls, nickel powder, graphene oxide dispersion liquid and alcohol into a ball mill tank, and ball mill for 5 hours. As the ball milling progresse...

Embodiment 3

[0063] The difference from Example 2 is that in this example, the mass ratio of metallic nickel and graphene in the composite material is changed, and the process parameters are adjusted according to the formula.

[0064] The basic operation steps of present embodiment 3 preparation graphene / copper composite material are as follows:

[0065] Ⅰ) Material composition of graphene / nickel composites

[0066] The material composition of the graphene / copper composite material is mainly metal nickel and graphene, wherein the mass fraction of nickel is 95wt%; the mass fraction of graphene is 5wt%. The raw material of graphene is graphene oxide.

[0067] Ⅱ) Basic steps for preparing graphene / nickel composites (see attached figure 1 )

[0068] 1) taking by weighing 50g of copper-nickel alloy powder and 30ml concentration is the graphene oxide dispersion of 0.088g / ml;

[0069] 2) According to the ball-to-material ratio of 20:1, put grinding balls, nickel powder, graphene oxide dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com