Sour plum wine and preparation method thereof

A technology of green plum wine and green plum, which is applied in the field of wine making to achieve the effect of reducing acidity, long aftertaste and golden wine body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

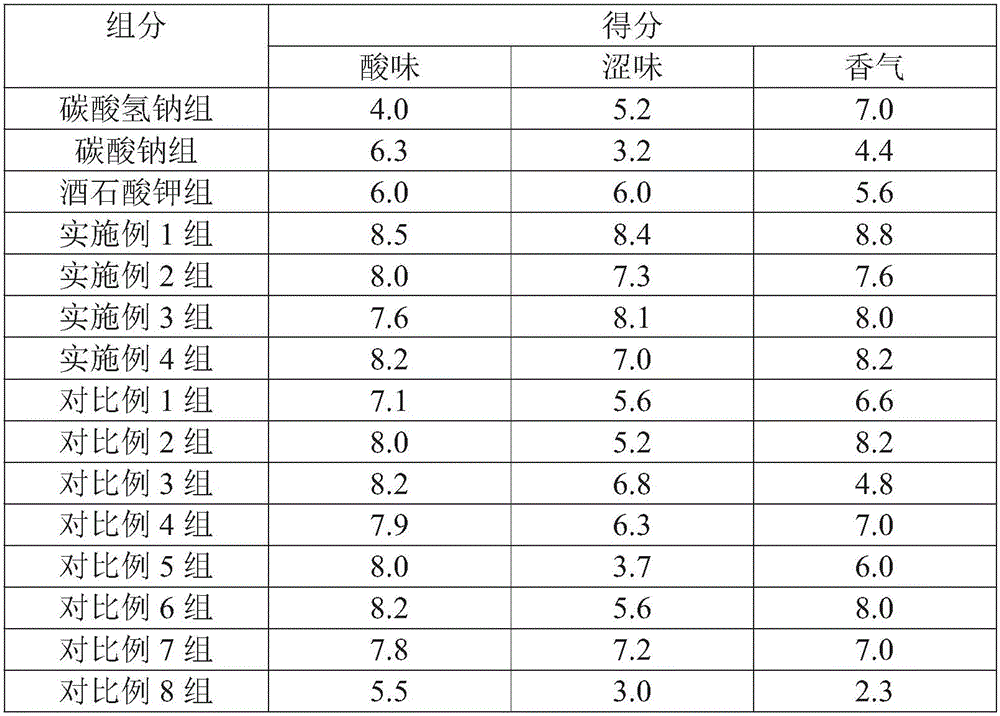

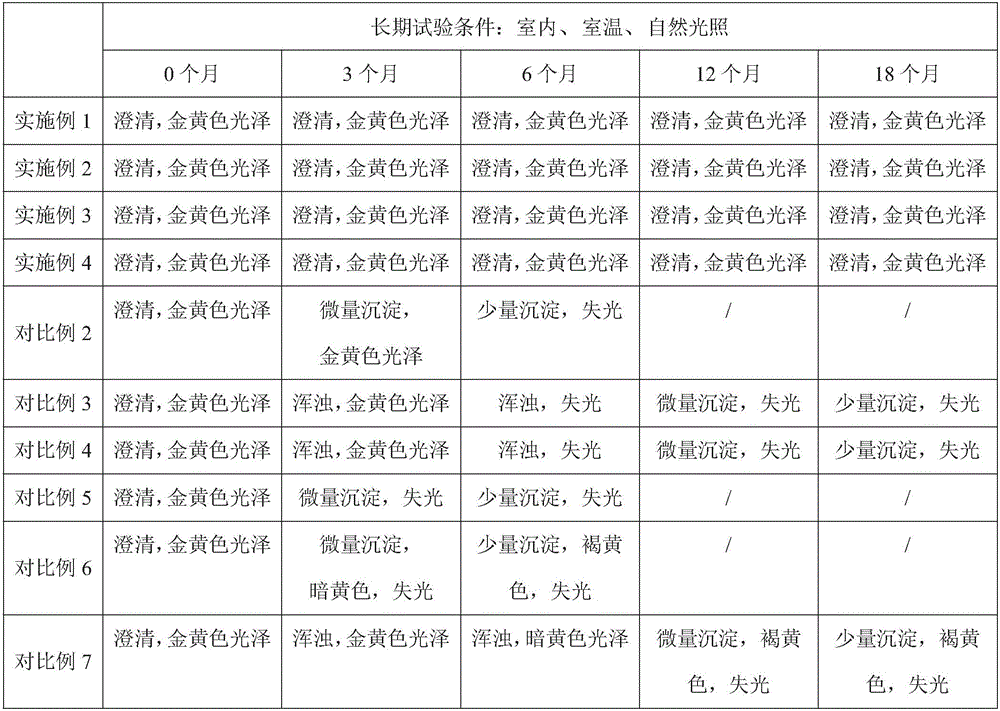

Examples

Embodiment 1

[0025] Embodiment 1, plum wine of the present invention and its preparation

[0026] S1. Select 100kg of fresh greengage without rot and pests, wash, remove the core, drain, and crush, weigh the greengage pieces according to the material-to-liquid ratio of 16g / 1L and put them in a dipping tank, then add boiling water to soak the greengage pieces. Cool naturally to room temperature, then add 0.4% pectinase and 0.5% cellulase in boiling water, carry out enzymatic hydrolysis at 35°C for 5 hours, filter and separate pomace with gauze to obtain greengage juice;

[0027] S2, add acid reducer to the green plum juice obtained in S1, adjust the acid content of green plum juice to be lower than 6g / L; then add white sugar to adjust the sugar content of green plum juice to be 18 ° Bx, inoculate yeast, the inoculation amount is green plum 10% of the juice volume, carry out alcoholic fermentation at 25°C for 7 days to obtain raw wine;

[0028] S3. Mix the original wine obtained in S2 with ...

Embodiment 2

[0032] Embodiment 2, plum wine of the present invention and its preparation

[0033] S1. Select 100kg of fresh greengage without mildew and no pests and diseases, wash, remove the core, drain, and crush, weigh the greengage pieces according to the material-to-liquid ratio of 12g / 1L and put them in a dipping tank, then add boiling water to soak the greengage pieces, and wait Cool naturally to room temperature, then add 0.2% pectinase and 0.4% cellulase in boiling water, carry out enzymatic hydrolysis at 30°C for 4 hours, use gauze to filter and separate pomace, and obtain greengage juice;

[0034]S2, add acid reducer to the green plum juice obtained in S1, adjust the acid content of green plum juice to be lower than 5g / L; then add white granulated sugar to adjust the sugar content of green plum juice to be 16 ° Bx, inoculate yeast, the inoculation amount is green plum 8% of the juice volume, carry out alcoholic fermentation at 20°C for 6 days to obtain raw wine;

[0035] S3. M...

Embodiment 3

[0039] Embodiment 3, plum wine of the present invention and its preparation

[0040] S1. Select 100kg of fresh greengage without mildew and no pests and diseases, wash, remove the core, drain, and crush, weigh the greengage pieces according to the material-to-liquid ratio of 18g / 1L and put them in a dipping tank, then add boiling water to soak the greengage pieces. Cool naturally to room temperature, then add 0.5% pectinase and 0.6% cellulase by weight of boiling water, carry out enzymolysis at 40°C for 6 hours, filter and separate pomace with gauze to obtain greengage juice;

[0041] S2, add acid reducer to the green plum juice obtained in S1, adjust the acid content of green plum juice to be lower than 8g / L; then add white granulated sugar to adjust the sugar content of green plum juice to be 20 ° Bx, inoculate yeast, the inoculation amount is green plum 12% of the juice volume, carry out alcoholic fermentation at 25°C for 8 days to obtain raw wine;

[0042] S3. Mix the ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com