A kind of microgel aqueous acrylic shell core resin emulsion and preparation method thereof

A resin emulsion and acrylic technology, applied in coatings and other directions, can solve problems such as failure of coating protection and aesthetic performance, reduction of solid content in coating construction, and reduction of coating film aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

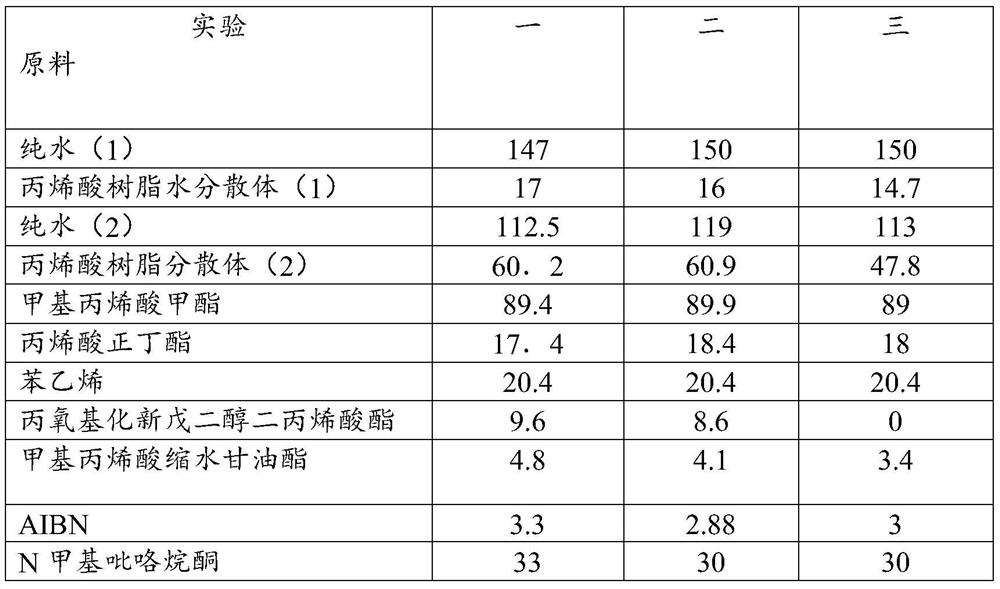

[0022] The material ratio is as follows

[0023]

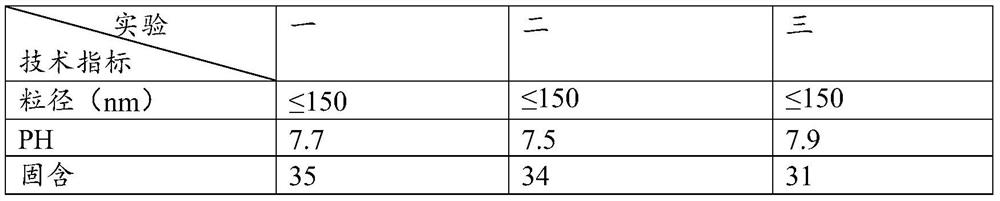

[0024] The experimental equipment used in the present invention is a constant temperature water bath, a four-necked bottle, a dropping funnel, and a spherical condenser. Pure water (1) and acrylic acid aqueous dispersion (1) are put into the four-necked bottle, and the stirring is started and the temperature is raised; at the same time Pure water (2), acrylic acid aqueous dispersion (2) and all acrylic acid monomers and vinyl monomers are uniformly stirred and mixed as emulsified monomer mixture components; initiator and solvent are stirred and mixed uniformly as initiator components for later use. Raise the temperature to 80°C±2°C and keep it. At this temperature, use two dropping funnels to add the emulsified monomer mixture component and the initiator component dropwise to the four-necked bottle at the same time, and drop them simultaneously for 4-6hr Complete, heat preservation 1hr cooling discharge. The technical indi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com