Nanometer ceramic intermediate film laminated hollow glass and manufacturing method thereof

A technology of nano-ceramics and production methods, applied in chemical instruments and methods, glass/slag layered products, lamination, etc., can solve the problems of increasing visible light reflection, increasing power consumption, increasing material costs, etc., to reduce heating and temperature increase function, reduce air-conditioning energy consumption, and increase selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

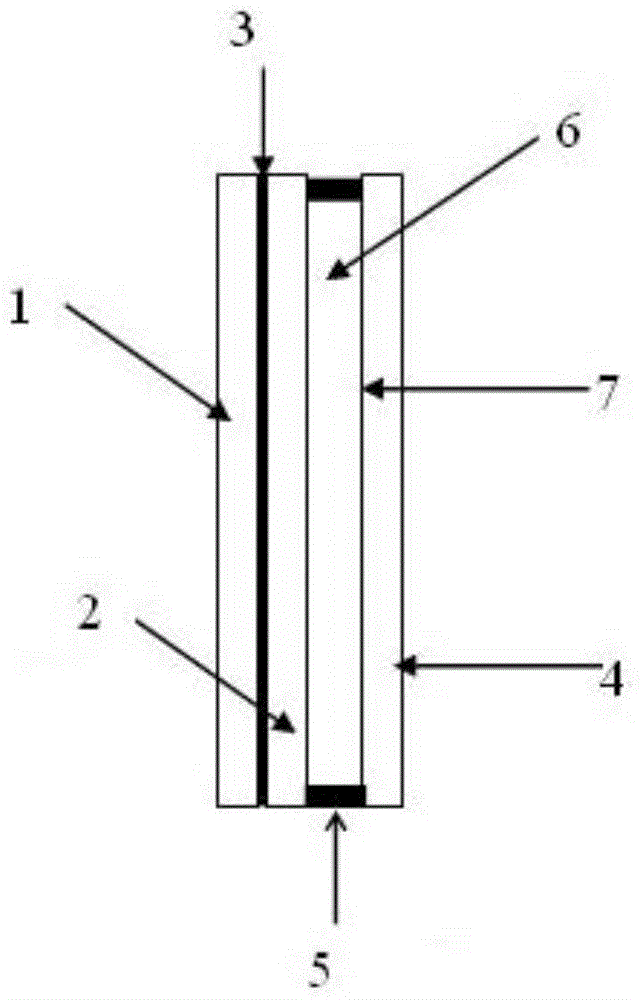

[0042] A nano-ceramic interlayer laminated insulating glass, comprising a first layer of glass 1 and a second layer of glass 2, and a composite tungsten oxide nano-ceramic dispersion liquid is sandwiched between the first layer of glass 1 and the second layer of glass 2 Modified PVB adhesive film 3, a third layer of Low-E glass 4 is arranged on one side of the second layer of glass 2; a hollow glass spacer is passed between the second layer of glass 2 and the third layer of Low-E glass 4 5 bonding and sealing, and forming a hollow layer 6; the Low-E film layer 7 of the Low-E glass faces the second layer of glass.

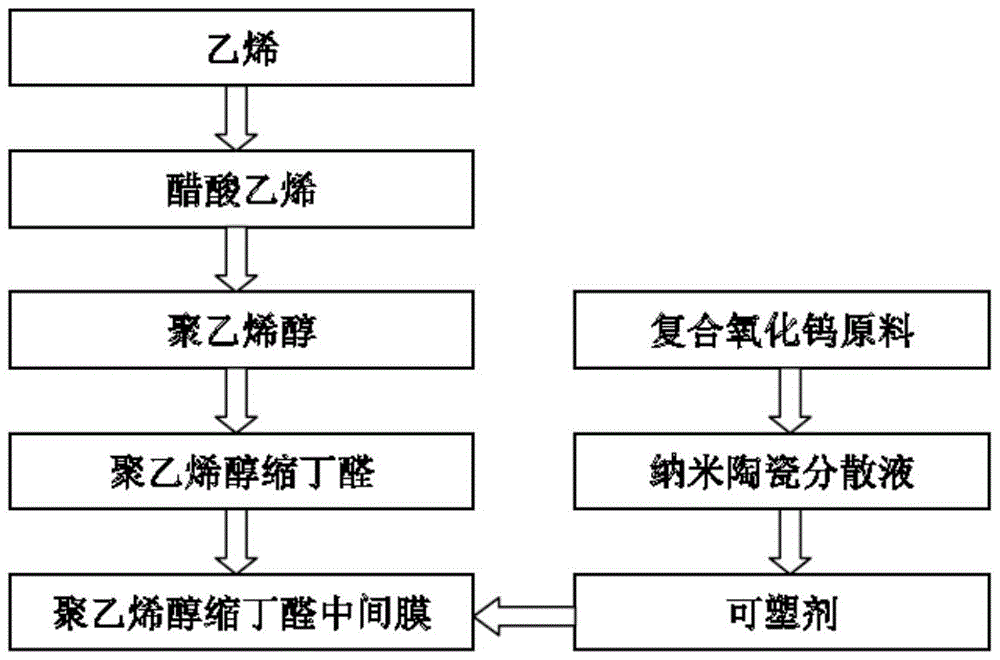

[0043]The modified PVB film mixed with composite tungsten oxide nano-ceramic dispersion liquid is prepared from inorganic composite tungsten oxide, plasticizer and polyvinyl butyral as main raw materials; High-performance nano-ceramic heat-insulating powder is made by wetting and grinding, and then the high-performance nano-ceramic heat-insulating powder is added to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com