Outer rotational flow limited flow channel membrane separator and method for demulsifying emulsion membrane through same

A technology of membrane separator and external swirling flow, which is applied in separation methods, semi-permeable membrane separation, chemical instruments and methods, etc. It can solve the problems of reduced separation efficiency, aggravated plugging, and short installation time, and achieves good demulsification effect , good permeability, good self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

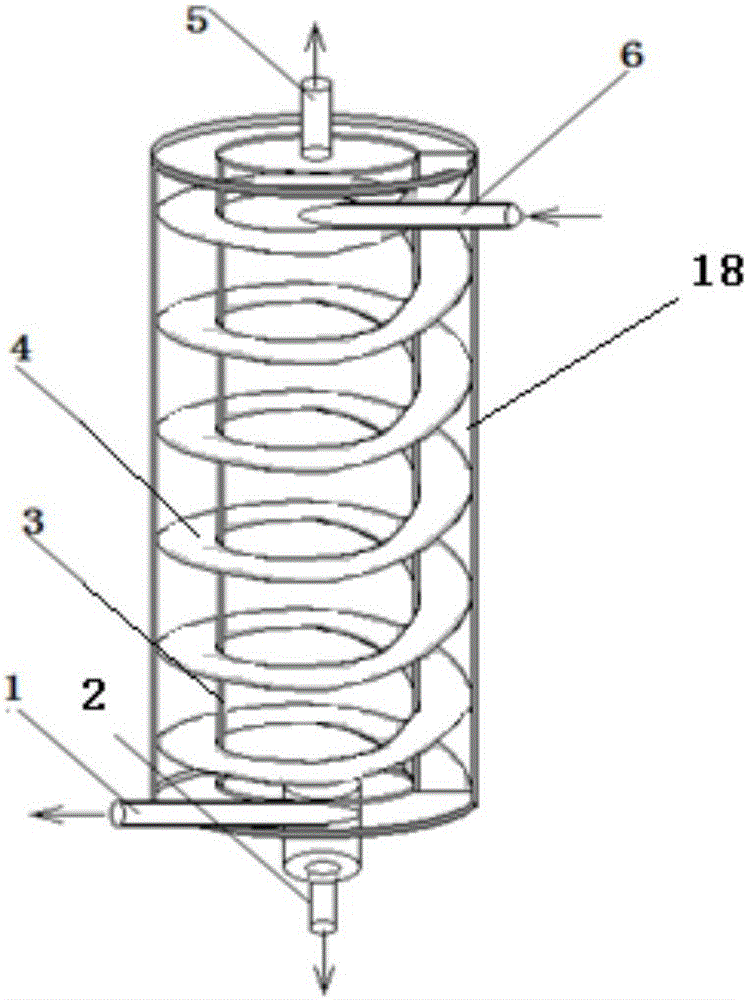

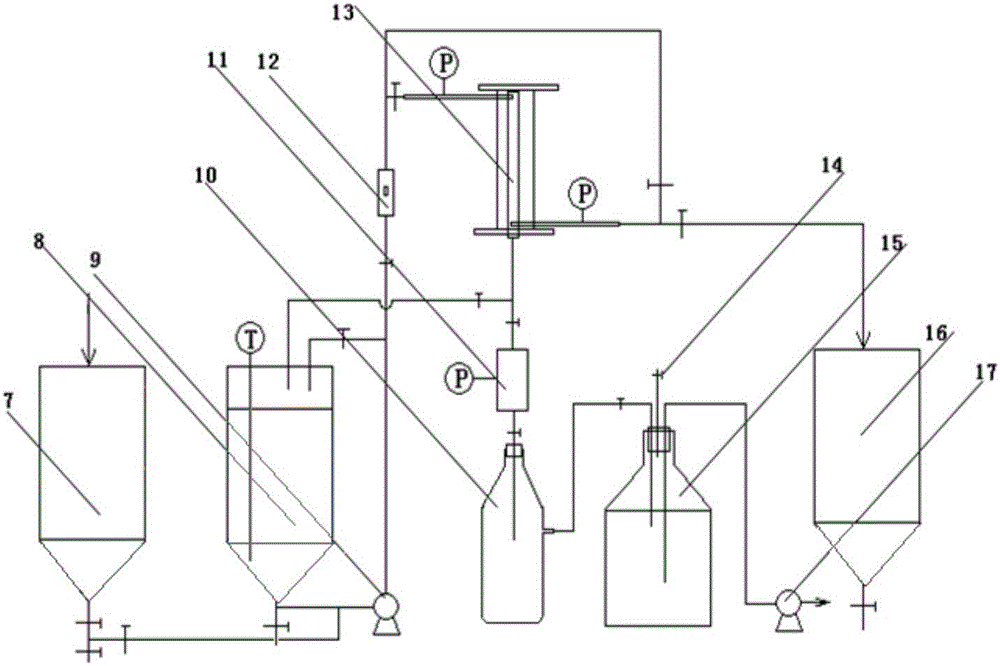

[0019] An external swirling flow restrictor membrane separator and its method for demulsifying emulsion liquid membrane, such as figure 1 with figure 2 As shown, the external swirl flow restrictor membrane separator includes a round tube housing 18, an emulsion outlet 1, an inner water phase material liquid outlet 2, a membrane separation tube 3, a restrictor swirl plate 4, a pressure measuring port 5, and a material Inlet 6, the round tube shell 18 is a cylindrical hollow tube; the emulsion outlet 1 is horizontally arranged at the lower part of the round tube shell 18; the inner water phase material liquid outlet 2 is arranged at the bottom center of the round tube shell 18; The membrane separation tube 3 is arranged inside the circular tube shell 18 and is arranged concentrically with the cross-sectional circle of the circular tube shell 18; the restrictor swirl plate 4 is spirally shaped along the outside of the membrane separation tube 3 It is arranged on the outside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com