Alcohol extracting device for dioctyl phthalate production system

A technology of dioctyl phthalate and production system, which is applied in the field of alcohol extraction devices of dioctyl phthalate production system, can solve the problems of easily polluted environment, product waste, polluted environment, etc. The effect of improving the thermal insulation effect and reducing the cost of water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

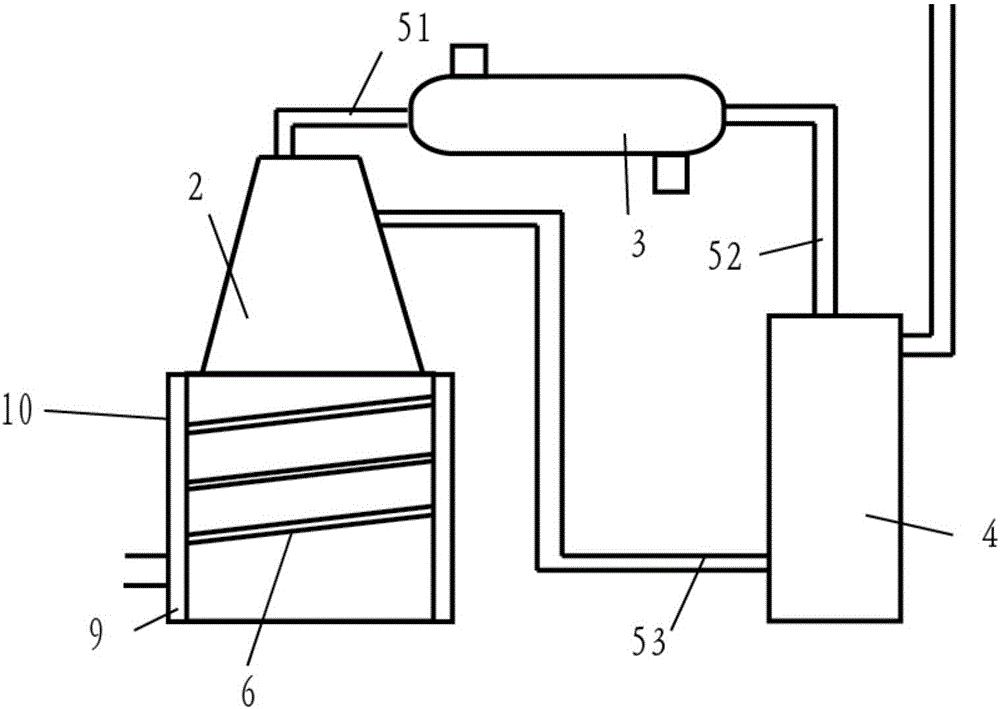

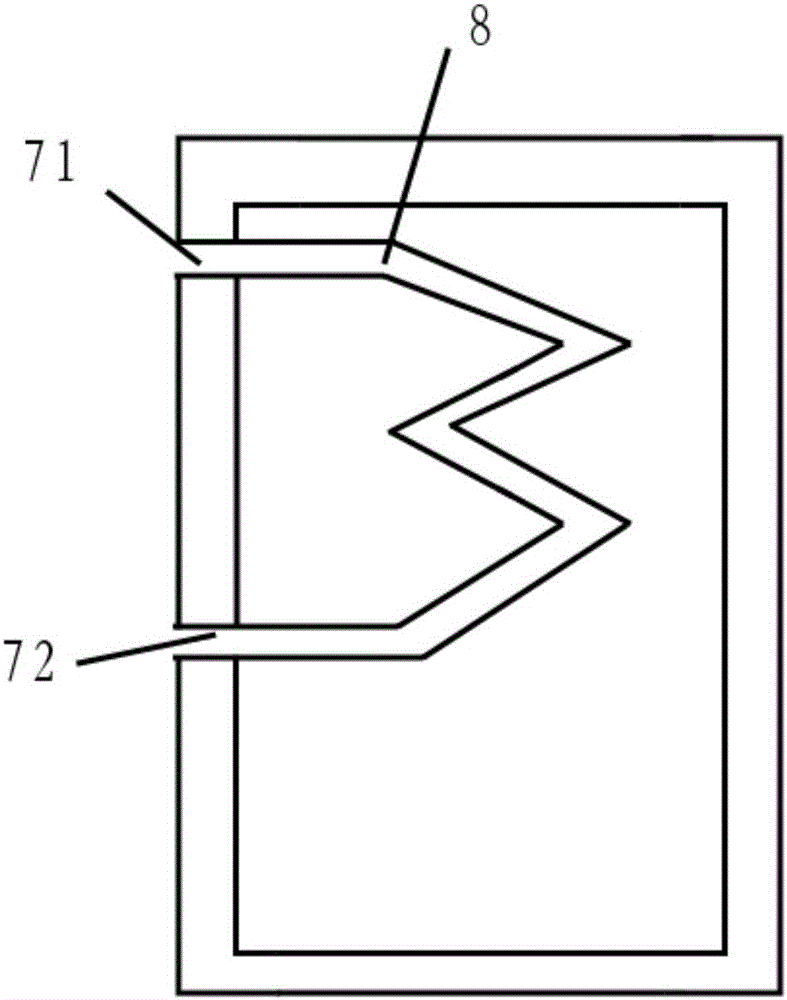

[0022] Such as Figure 1-2 As shown, the present invention discloses an alcohol extraction device for a dioctyl phthalate production system, including a heating tank, a waste water tower 2, a condenser 3, and a liquid separation tank 4. The top of the heating tank 1 is provided with a waste water tower 2, the top of the waste water tower 2 communicates with the air inlet of the condenser 3 through the first pipeline 51, and the liquid outlet of the condenser 3 communicates with the upper end of the liquid separation tank 4 through the second pipeline 52. connected. The liquid separation tank 4 is provided with a water outlet and an alcohol outlet. The water outlet is located below the alcohol outlet.

[0023] Preferably, the alcohol outlet is in communication with the reactor of the dioctyl phthalate production system.

[0024] Preferably, the condenser 3 is a shell and tube condenser.

[0025] Preferably, the water outlet communicates with the wastewater tower 2 through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com