Hydroponic system for high-throughput maize roots

A hydroponic system and high-throughput technology, applied in the field of plant soilless cultivation, can solve the problems of small number of seedlings, easy slipping or lodging, uneven oxygen supply, etc., to achieve uniform size, high root system vitality, and uniform ventilation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0015] The application principle of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

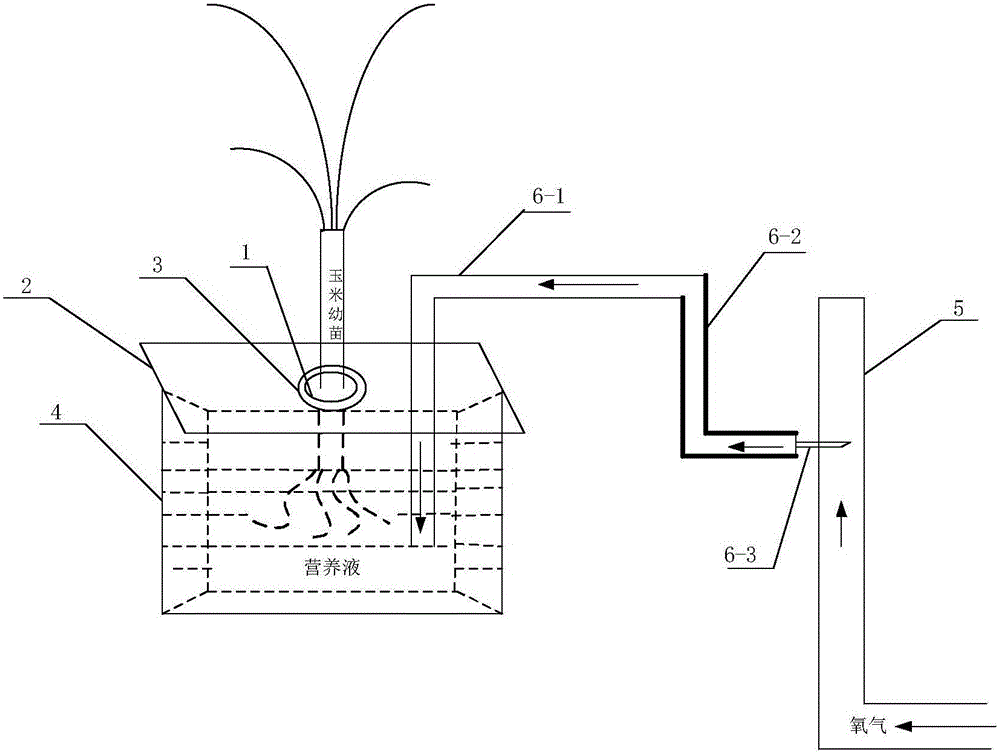

[0016] As shown in Figure 1: a kind of hydroponic system that is used for high-throughput corn root system, comprises the sponge 1 of cylindrical shape, culture plate 2, culture plate circular hole 3, hydroponic box 4, ventilation main pipe 5 and ventilation branch pipe 6; Cylindrical sponge 1 blocks the corn seedlings and inserts them into the round hole 3 of the culture plate, and the culture plate 2 is placed flat on the hydroponic box 4 filled with nutrient so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com