Electric machine with corresponding at least two clamping lugs for fixing permanent magnets

A permanent magnet and clamping technology, which is applied in the direction of magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of difficult installation of permanent magnets, and achieve the effects of small torque fluctuation, small positioning torque, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

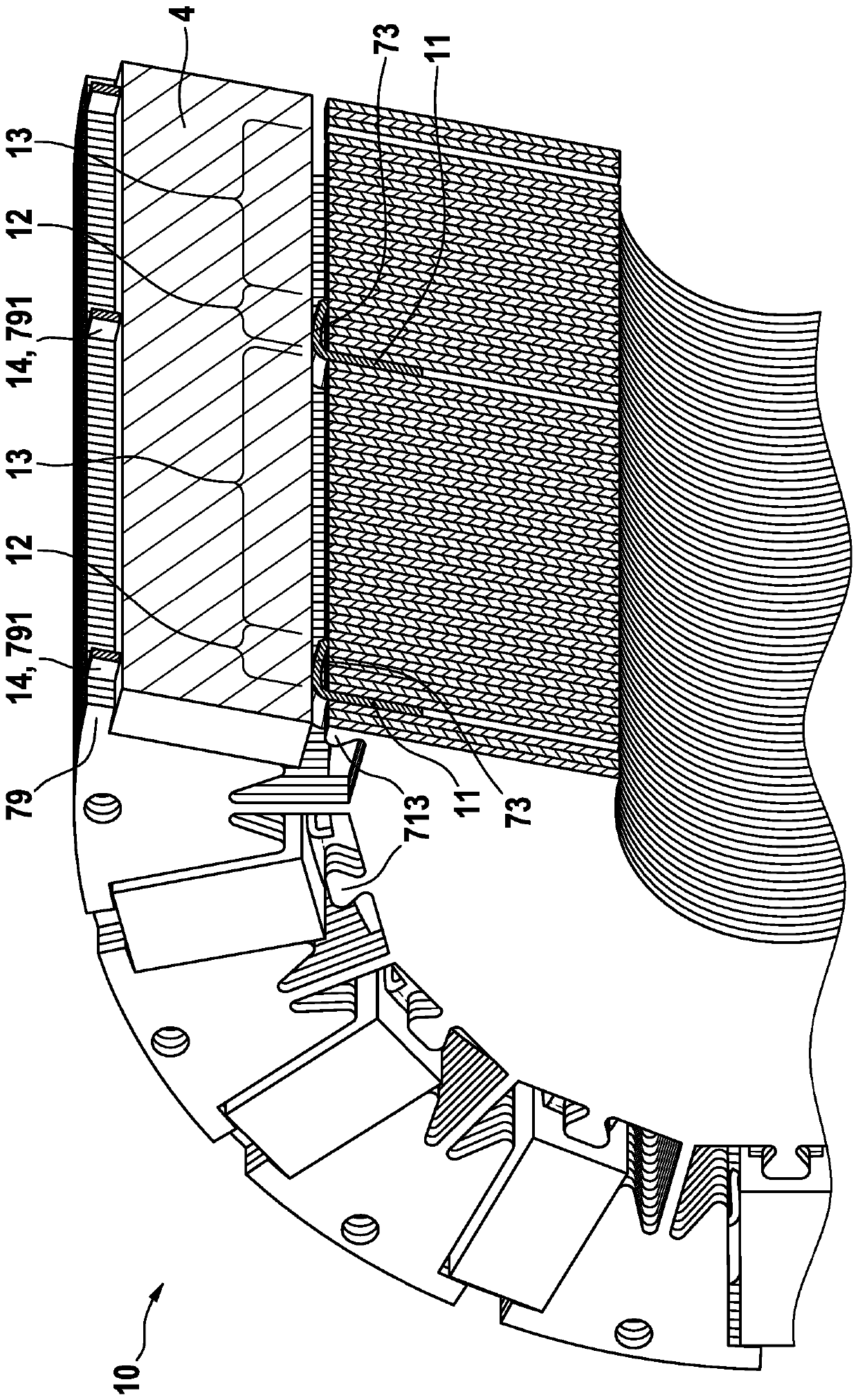

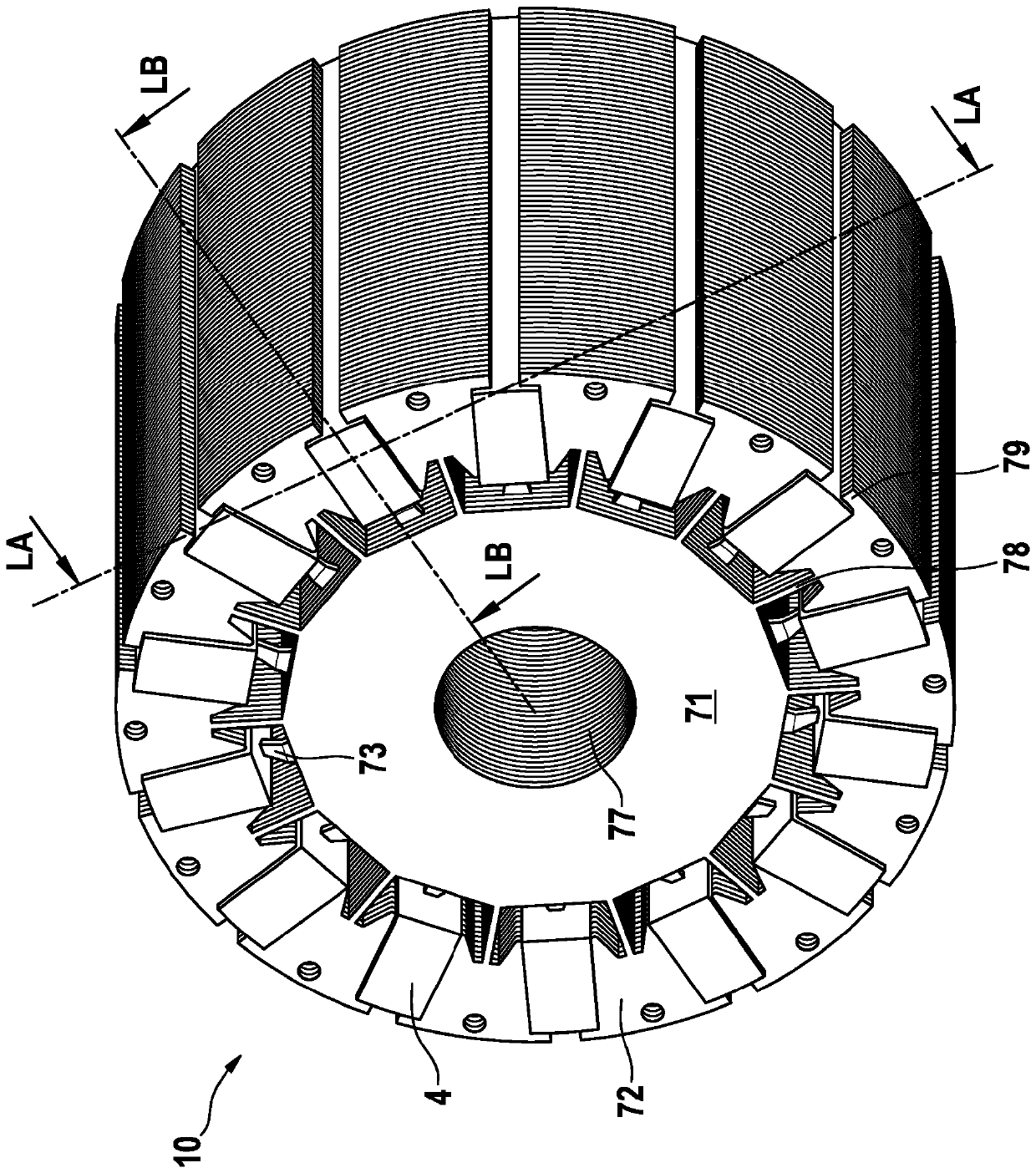

[0046] figure 1 The electrical machine 100 has an inner rotor 10 which is configured as a spoked rotor and extends concentrically around a shaft 20 capable of surrounding an axis of rotation 2 (cf. Figure 2a-Figure 2g , Figure 3a-Figure 3h ) is supported in a rotational manner. Furthermore, the electric machine has a stator 50 arranged on the outside.

[0047] The stator 50 has a yoke 53 on which a plurality of teeth 52 are arranged. With the stator 50 installed, the teeth 52 are wound with windings 54 which are provided for generating an alternating magnetic field. To this end, gaps 51 for receiving the windings 54 are provided between the teeth 52 . However, in figure 1 For the sake of clarity, only one winding 54 is shown exemplarily.

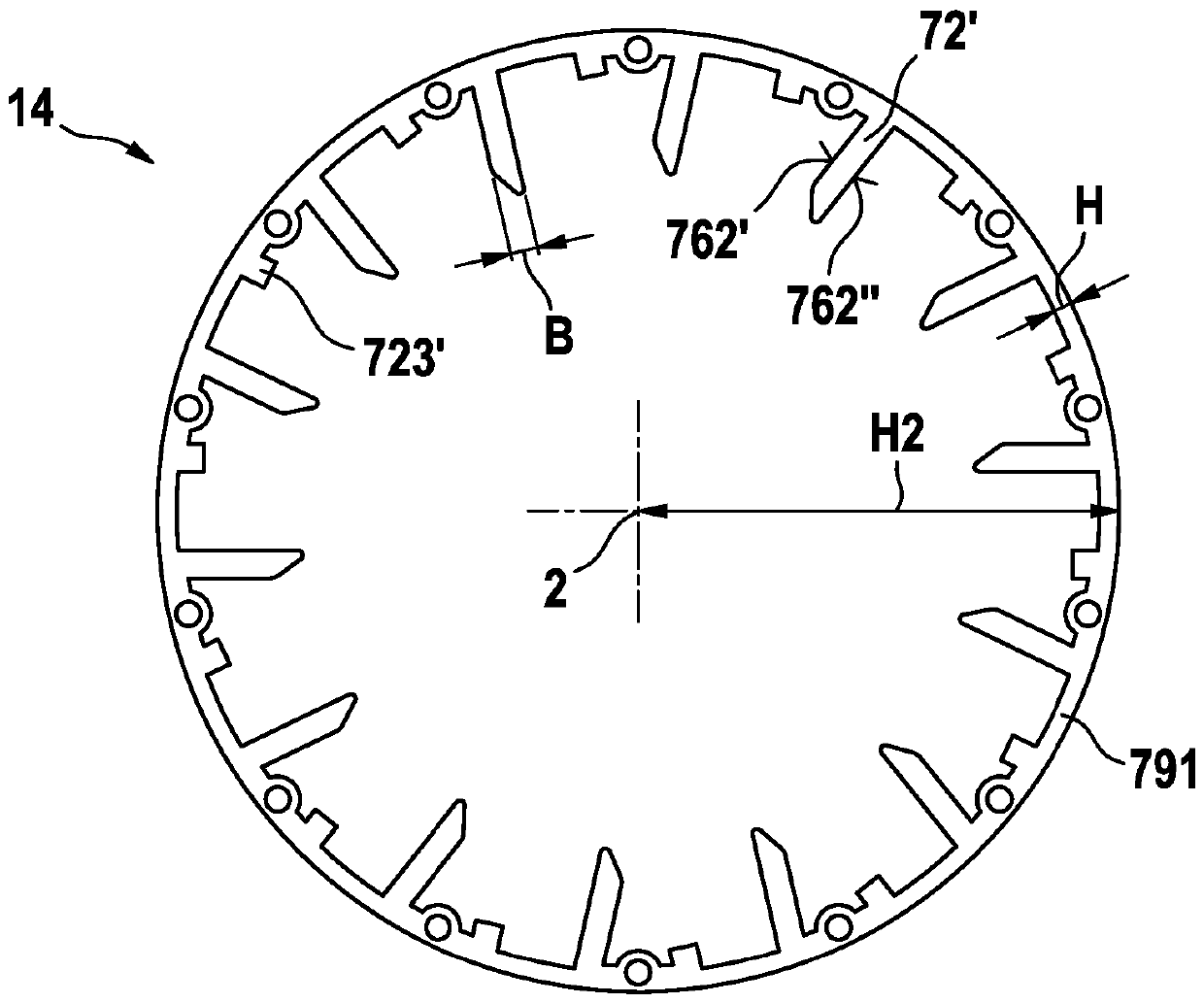

[0048] The spoked rotor 10 has an inner ring 71 which extends concentrically around the axis of rotation 2 and has a through hole 77 in the center (cf. Figure 2a-Figure 2g , Figure 3a-Figure 3h ), the through hole is configured t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com