Five power-on bus distributing style with different current

A configuration method and isoelectric technology, applied in the installation of busbars, electrical components, cables, etc., can solve the problems of production and operation hazards, sharp increase in horizontal magnetic field, and damage to the stability of electrolytic cells, and achieve the effect of reducing hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

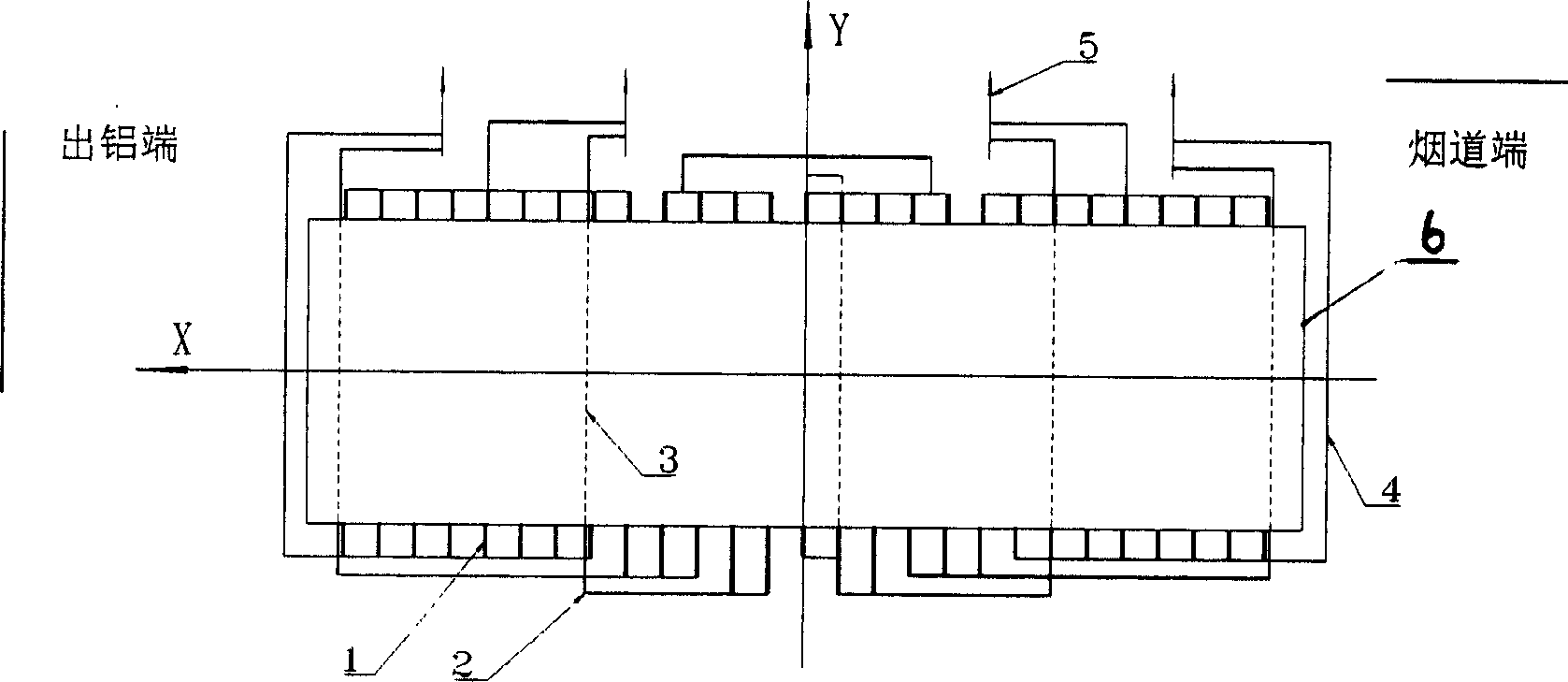

[0009] Embodiment of the present invention: 50% of the current in the electrolytic cell (6) flows out through 27 cathode soft busbars (1) on the A side, and flows into the five tank bottom busbars (3) and 2 after passing through the A side cathode busbars (2) The first trough side busbar (4) flows into 5 downstream trough column busbars (5); each segment A-side cathode busbar (2) and 5 trough bottom busbars (3), 2 trough side busbars (4) and 5 The busbars (5) of the downstream trough columns are respectively connected by welding. Another 50% of the current in the electrolytic cell (6) flows out through 27 cathode soft busbars on the B side, and then flows into the downstream cell column busbar (5) through the cathode busbars on the B side. The cathode bus bars on the B side of each segment and the column bus bars of the downstream slots are respectively connected by welding.

[0010] The current flowing out from the A and B sides of the electrolytic cell (6) flows into 5 colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com