Electrolytic tank magnetic field external compensation device

A compensation device and electrolytic cell technology, applied in the field of external compensation devices, can solve the problems of high investment cost, large compensation current at the flue end, and limited use of compensation methods, and achieve high current efficiency, reduce vertical magnetic fields, and solve the effects of magnetic field problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

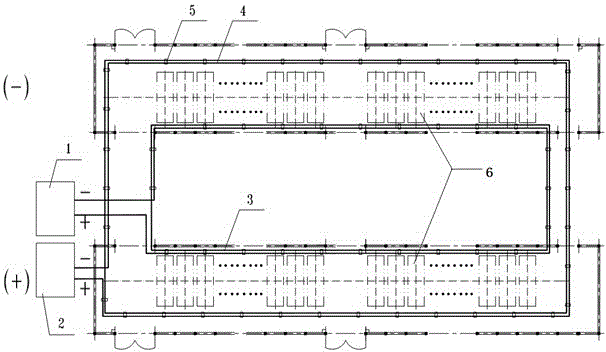

[0020] like figure 1 As shown, an external compensation device for the magnetic field of an electrolytic cell includes a series of electrolytic cells 6 arranged in parallel, a rectifier unit 1 at the flue end and a rectifier unit 2 at the aluminum outlet end. The flue end of the electrolytic cell 6 and the aluminum outlet end each form a closed loop with two turns. The flue end surrounds the busbar 3 and the aluminum outlet end surrounds the busbar 4 and is fixed by the busbar bracket 5. The surrounding busbar is an aluminum busbar with an aluminum content of 99.5%, and the flue end surrounds The busbar 3 and the aluminum outlet end surround the busbar 4 with the same diameter, and the current density around the busbar is 0.3A / mm 2 .

Embodiment 2

[0022] An external compensation device for the magnetic field of an electrolytic cell, comprising a series of electrolytic cells 6 arranged in parallel, a flue end rectifier unit 1 and an aluminum outlet end rectifier unit 2, the flue end surrounds the bus bar 3 and forms a three-turn closure along the flue end of the electrolytic cell 6 Circuit, the aluminum outlet end surrounds the busbar 4 and forms a closed loop with two turns along the electrolytic cell 6 aluminum outlet end, the flue end surrounds the busbar 3 and the aluminum outlet end surrounds the busbar 4 and is fixed by the busbar bracket 5, and the surrounding busbar is made of aluminum with an aluminum content of 99.6% The busbar, the flue end surrounds the busbar 3, and the aluminum outlet end surrounds the busbar 4 with the same diameter, and the current density around the busbar is 0.3A / mm 2 .

Embodiment 3

[0024] An external magnetic field compensation device for an electrolytic cell, comprising a series of electrolytic cells 6 arranged in parallel, a flue end rectifier unit 1 and an aluminum outlet end rectifier unit 2, the flue end surrounds a bus 3, and the aluminum outlet surrounds a bus 4 respectively along the electrolytic cell 6. The flue end and the aluminum outlet end each form a closed loop. The flue end surrounds the busbar 3 and the aluminum outlet end surrounds the busbar 4 and is fixed by the busbar bracket 5. The surrounding busbar is an aluminum busbar with an aluminum content of 99.7%. The current density around the busbar is 0.4A / mm 2 , and the diameter of the flue end surrounding the bus bar 3 is larger than the diameter of the aluminum outlet end surrounding the bus bar 4 . The alternating current passes through the flue end rectifier unit 1 and the aluminum outlet end rectifier unit 2 into different direct currents, and then is connected to the electrolysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com