Bottom-discharging aluminum cell

An aluminum electrolytic cell and electrolytic cell technology, applied in the field of aluminum electrolytic cells, can solve the problems of large vertical magnetic field, uneven current distribution, and violent fluctuation of molten aluminum, so as to reduce the vertical magnetic field, improve the distribution uniformity, and slow down the vertical fluctuation amplitude. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

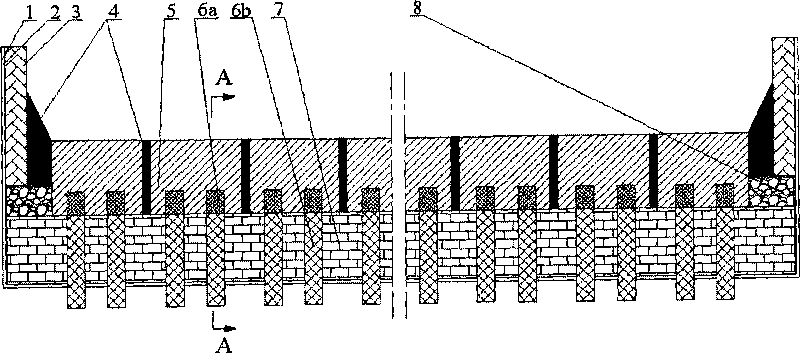

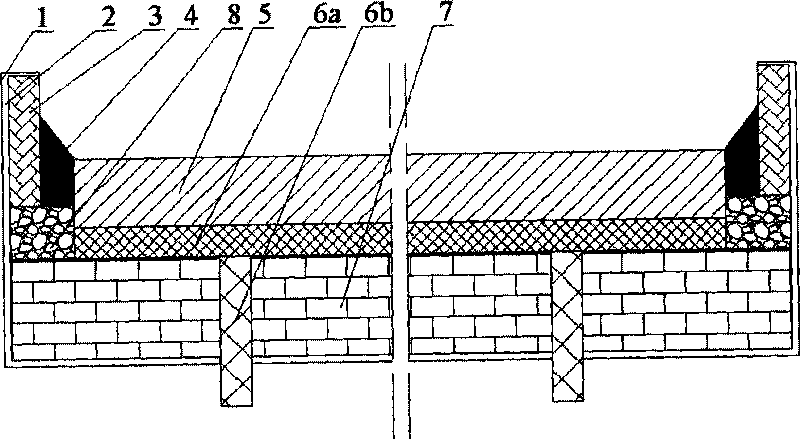

[0026] Such as figure 1 As shown, the novel cathode structure aluminum electrolytic cell of the present invention consists of steel tank shell 1, asbestos board 2, side lining 3, tamping paste 4, cathode carbon block 5, horizontal cathode steel rod 6a, vertical cathode steel rod 6b , refractory material and insulation material 7 and castable 8 components. Wherein, a horizontal long cathode steel rod is equipped with two vertical cathode steel rods (such as figure 2 shown), the location of the connection between the vertical cathode steel rod and the horizontal cathode steel rod is determined by physical field calculations. In this example, the best connection point is 1 / 4 to 3 / 4 of the horizontal steel rod. Due to the relatively uniform conductive distance from the cathode surface to the cathode steel rod, the structure can reduce the generation of horizontal current in the electrolytic cell, thereby reducing the interference of the vertical magnetic field to the aluminum li...

Embodiment 2

[0028] Such as figure 1 As shown, the novel cathode structure aluminum electrolytic cell of the present invention consists of steel tank shell 1, asbestos board 2, side lining 3, tamping paste 4, cathode carbon block 5, horizontal cathode steel rod 6a, vertical cathode steel rod 6b , refractory material and insulation material 7 and castable 8 components. Wherein, a horizontal long cathode steel rod is configured with four vertical cathode steel rods (such as image 3 shown), the selection of the connection position between the vertical cathode steel rod and the horizontal cathode steel rod is determined by the calculation of the physical field. In this example, the best connection points are 1 / 5~2 / 5 and 3 / 5~4 of the horizontal steel rod / 5 places. Because the conductive distance from the cathode surface to the cathode steel rod is more uniform in this structure, the generation of horizontal current in the electrolytic cell can be reduced. The scheme is applied to a 400kA a...

Embodiment 3

[0030] Such as Figure 4 As shown, the novel cathode structure aluminum electrolytic cell of the present invention is made of steel tank shell 1, asbestos board 2, side lining 3, tamping paste 4, cathode carbon block 5, plate-type horizontal cathode 14, vertical cathode steel rod 6b, The refractory material, the heat insulating material 7 and the casting material 8 are composed. Wherein, the bottom of the cathode steel bar is equipped with a horizontal cathode steel plate, and each horizontal cathode steel block can be equipped with two or four vertical cathode steel bars (such as figure 2 , image 3 shown), the connection position selection of the vertical cathode steel rod and the horizontal cathode steel rod can be determined by calculation to determine the best connection point. This structure conducts electricity at equidistant distances from the surface of the cathode to the cathode steel bar block, so its horizontal current will be smaller than that of Embodiment 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com