Low-energy-consumption method for separating ilmenites from tailings in iron choosing plant

A technology for iron concentrators and ilmenite, which is applied in the field of ilmenite separation, can solve the problems of ineffective dispersion of selected materials in separation tanks, low quality of magnetic concentrate products, and restrictions on industrial application, so as to prevent heavy Mineral deposition, advanced permanent magnetic circuit design, and the effect of improving ore feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

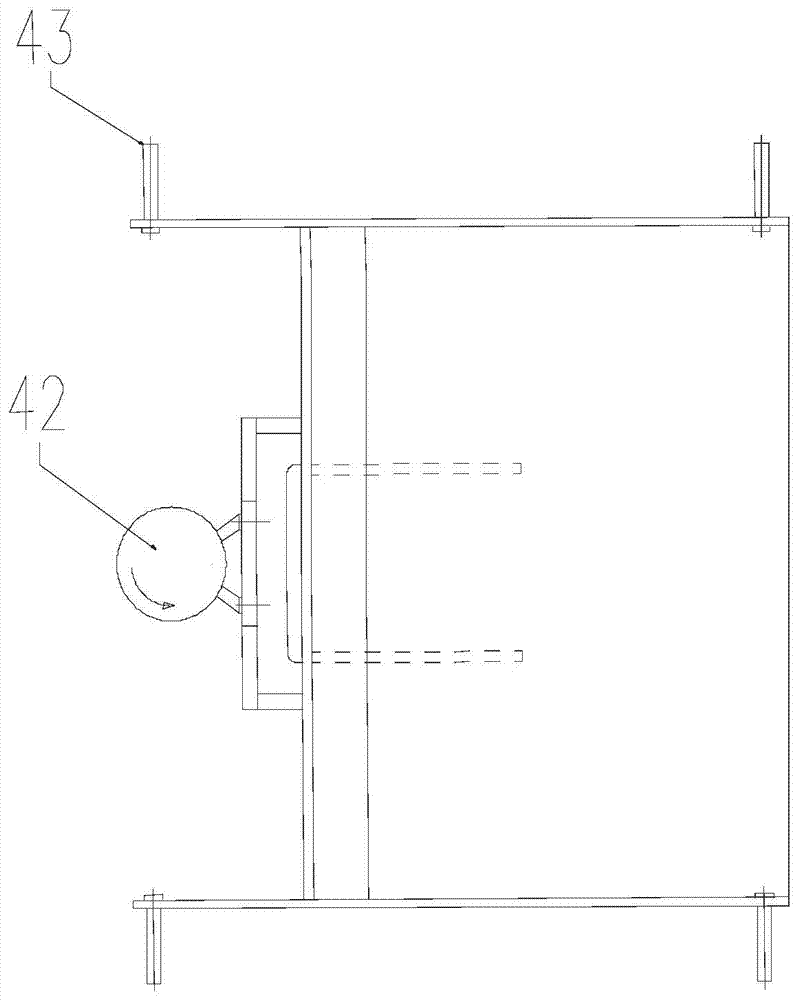

[0035] a kind of like Figure 5 Shown the method for the low energy consumption separation ilmenite of the present invention from iron dressing plant tailings, it is mainly aimed at certain ground iron dressing plant tailings, comprises the following steps:

[0036] (1) Permanent magnetic cylinder type strong magnetic separation:

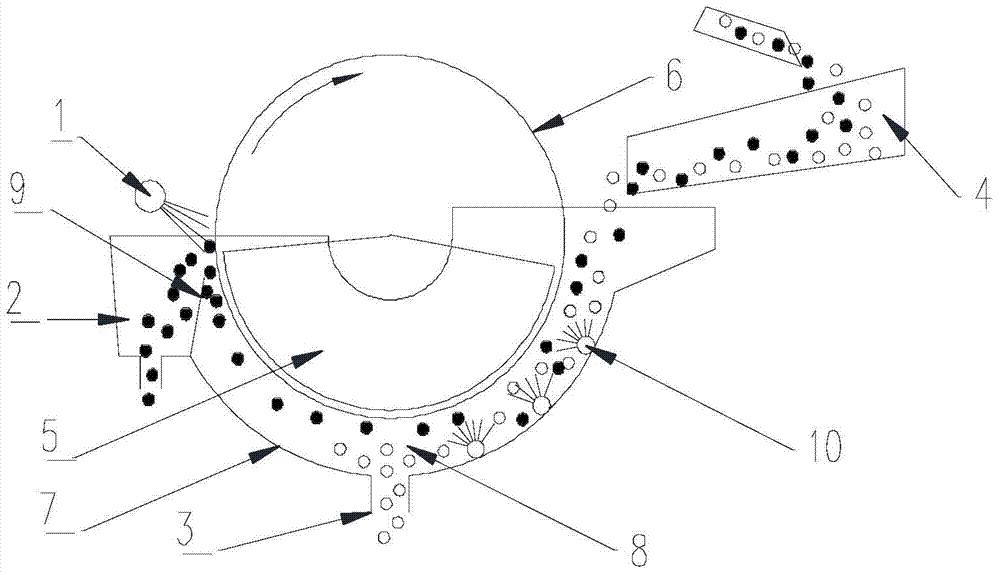

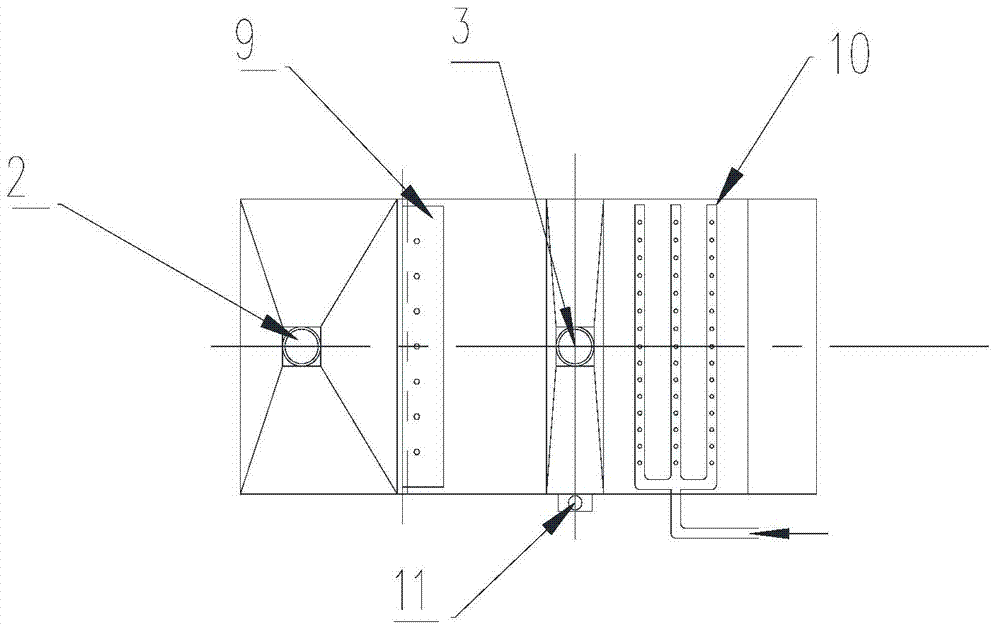

[0037] Using the tailings of the iron dressing plant as raw material, first use such as Figure 1 ~ Figure 3The shown permanent magnetic cylinder type medium magnetic separator sorts the raw material (the magnetic field strength is 8000GS), the non-magnetic material is directly discharged as magnetic separation tailings, and the medium magnetic separation concentrate as magnetic material enters the next step; through the present invention The pre-selection and tailing treatment of the permanent magnetic cylinder type magnetic separator greatly reduces the amount of material that needs to be ground again for "the tailings of the iron processing plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com