Magnetron assembly and magnetron sputtering equipment

A magnetron and component technology, which is applied in sputtering plating, ion implantation plating, metal material coating process, etc., can solve the problems of limited improvement and inability to find the size of the magnetron, and achieves convenient and shortened installation. time, the effect of improving the uniformity of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

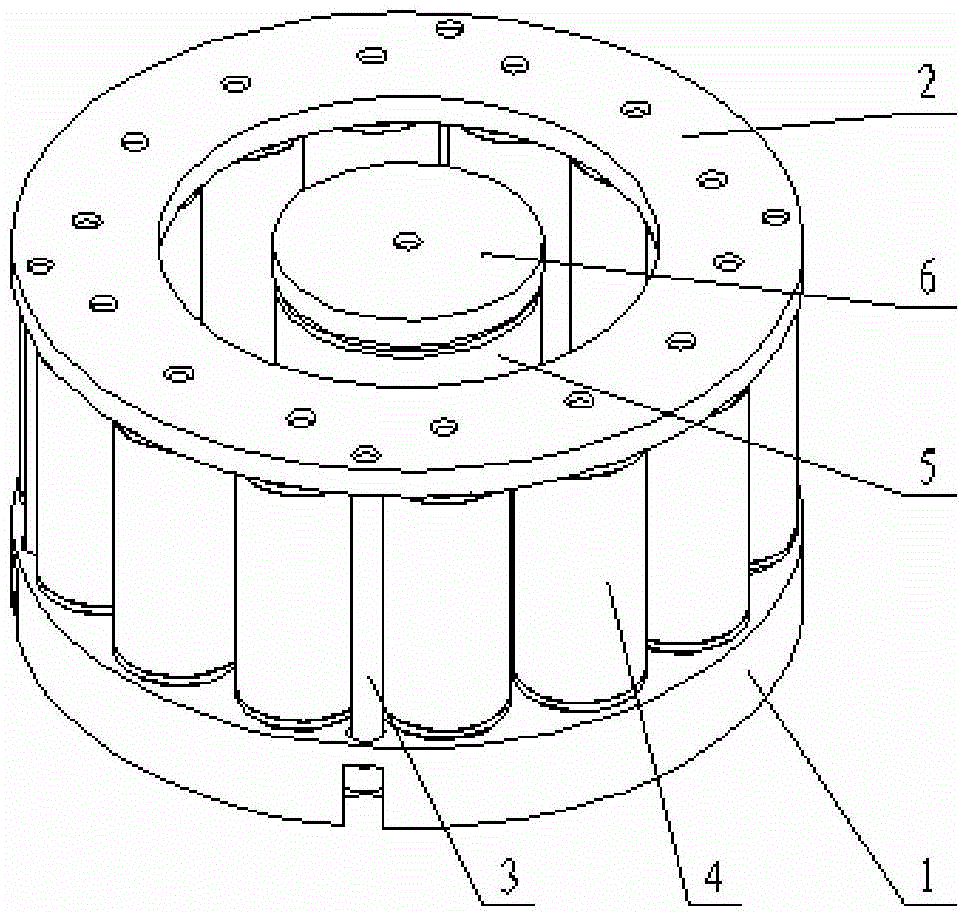

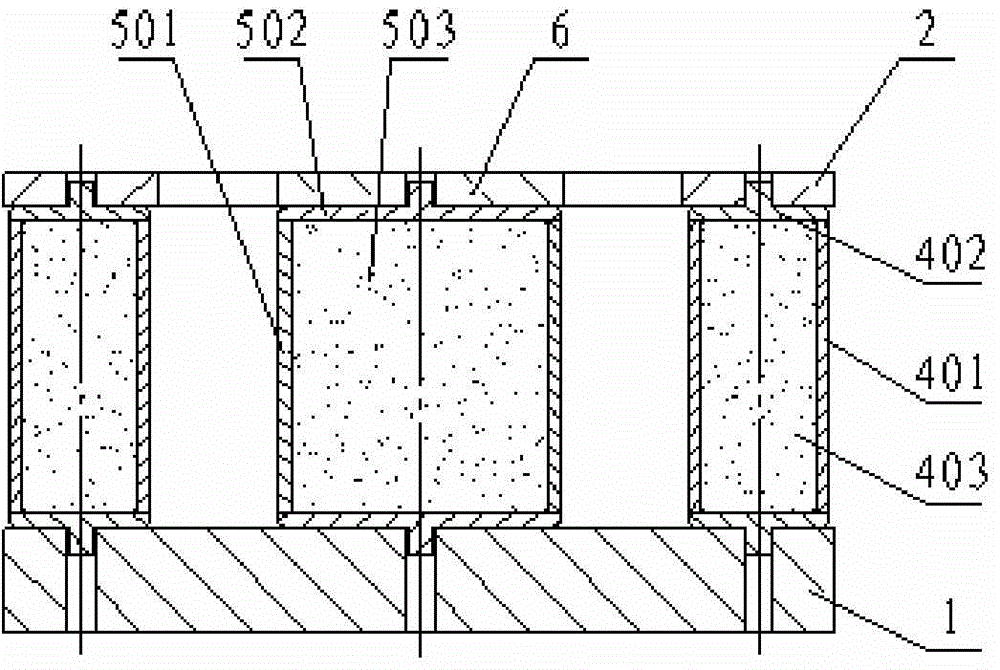

[0032] In order for those skilled in the art to better understand the technical solution of the present invention, the magnetron assembly and the magnetron sputtering equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0033] The magnetron assembly provided by the present invention includes a central permanent magnet and an annular permanent magnet surrounding the central permanent magnet. The central permanent magnet and the annular permanent magnet have opposite polarities; wherein the annular permanent magnet adopts an integrated structure. By adopting the ring-shaped permanent magnet of the above-mentioned one-piece structure as the outer ring magnet surrounding the central permanent magnet, the following advantages can be obtained:

[0034] First, the magnetron assembly provided by the present invention replaces a plurality of small magnets in the prior art by using an annular permanent magnet with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com