Production technology of quick-charge lithium battery

A production process and fast charging technology, applied in non-aqueous electrolyte battery, electrolyte battery manufacturing, secondary battery and other directions, can solve the problems of high manufacturing cost and slow charging, and achieve the effect of reducing production cost, fast charging and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

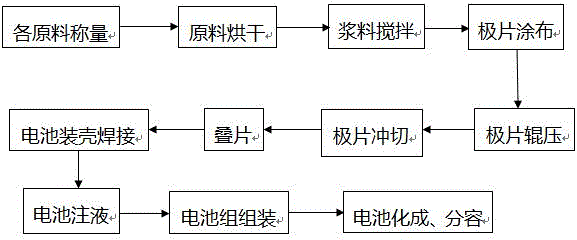

[0041] A kind of production technology of fast charging lithium battery, its steps are as follows:

[0042] a. Weighing of each raw material: shell 76g, multi-component positive electrode 186g, copper foil 30g, electrolyte 50g, mixed negative electrode 65g, separator 0.2㎡, conductive agent 0.6g, binder PVDF 0.5g, diluent 40 grams of NMP, 0.9 grams of thickener CMC, 20 grams of aluminum foil, 0.8 grams of tabs, 0.5 grams of insulating tape;

[0043] b. Drying of raw materials: vacuum bake the multi-component positive electrode in step a, bake the conductive agent at normal pressure, and bake the adhesive at normal pressure;

[0044] c. Stirring of the slurry: Pour NMP into a vacuum mixer, and add PVDF into it; add the positive electrode dry material in four times on average; stir at high speed under vacuum for 3-5 hours; discharge and prepare for coating;

[0045] d. Electrode coating: the slurry is evenly coated on the surface of the aluminum foil on a precision coating machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com