Porous silicon-carbon composite material and preparation method and application thereof

A carbon composite material and composite material technology, applied in the field of porous silicon-carbon composite material and its preparation, can solve the problems of difficult industrialization, high equipment requirements, high cost, etc., achieve short transmission distance and alleviate volume expansion effect , the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Heat-treat magnesium silicide at 700°C for 20 hours, and pass excess CO 2 80% CO by volume 2 / Ar mixed gas as the reaction gas.

[0031] 2) The product obtained in step 1) was treated for 10 hours in a certain concentration of hydrochloric acid solution, wherein the concentration of hydrochloric acid was 0.5 mol / liter, after the acid treatment, it was washed 5 times with deionized water, then centrifuged, and finally vacuum-dried.

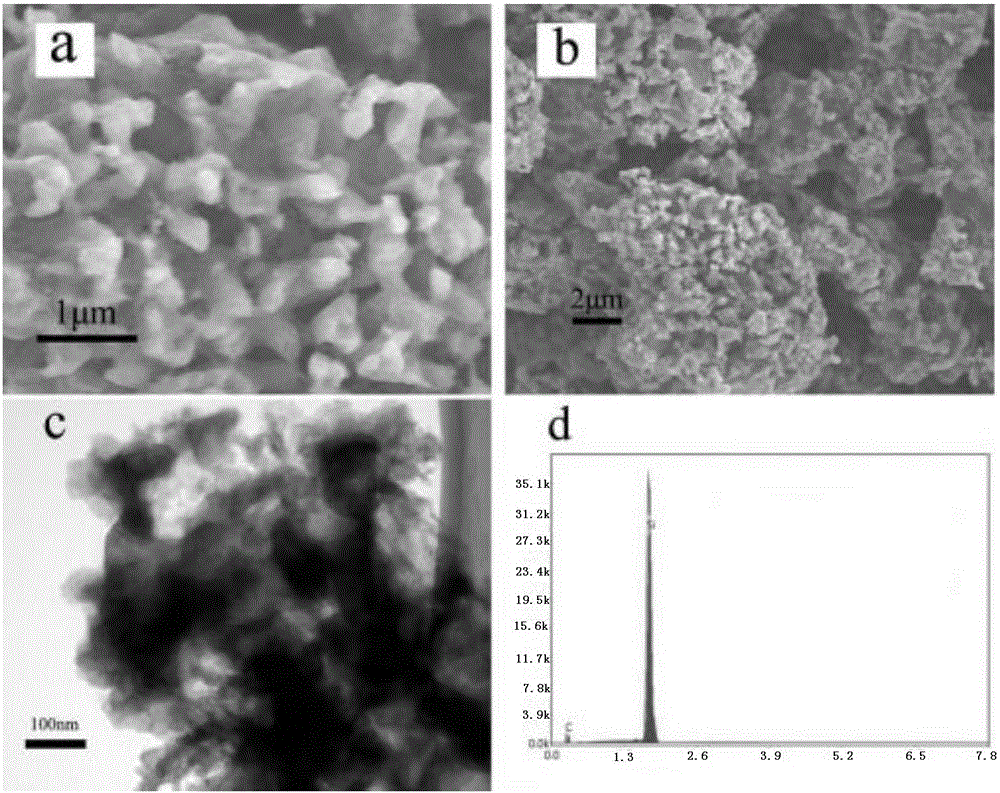

[0032] The relevant characterization results of the porous silicon-carbon composite material prepared in this example are as follows figure 1 shown. It can be seen from the figure that the product of this example is a porous structure with a large number of uniformly distributed nanoscale pores, the mass fraction of carbon is about 40%, and it is uniformly coated on the surface of silicon in the form of an amorphous carbon film, forming a porous structure with a core. -Silicon-carbon composite material with shell structure characterist...

Embodiment 2

[0036] The preparation process is exactly the same as in Example 1, the difference is only that CO 2 / Ar mixture, CO 2 The volume fraction is 60%. The morphology of the prepared porous silicon-carbon composite material is similar to that of Example 1, but the mass fraction of carbon is about 45%.

Embodiment 3

[0038] 1) Heat-treat magnesium silicide at 800°C for 15 hours, and pass excess CO 2 50% CO by volume 2 / Ar mixed gas as the reaction gas.

[0039] 2) The product obtained in step 1) was treated for 5 hours in a certain concentration of hydrochloric acid solution, wherein the concentration of hydrochloric acid was 2.0 mol / liter, after the acid treatment, it was washed 7 times with deionized water, then centrifuged, and finally vacuum-dried.

[0040] The morphology of the porous silicon-carbon composite material prepared in this example is similar to that of Example 1, but the mass fraction of carbon is about 46%.

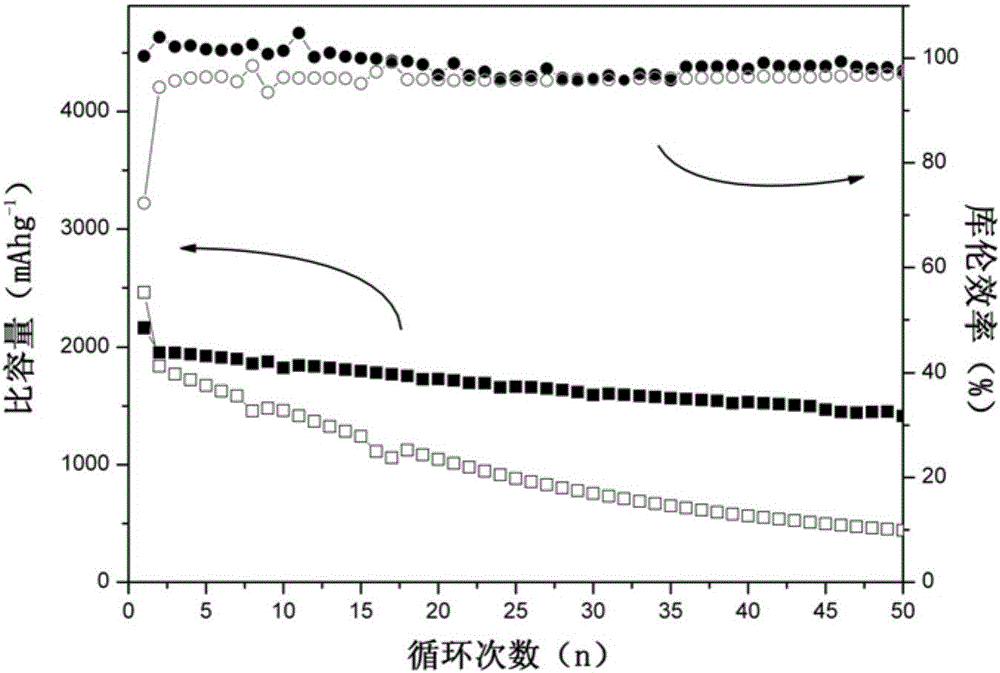

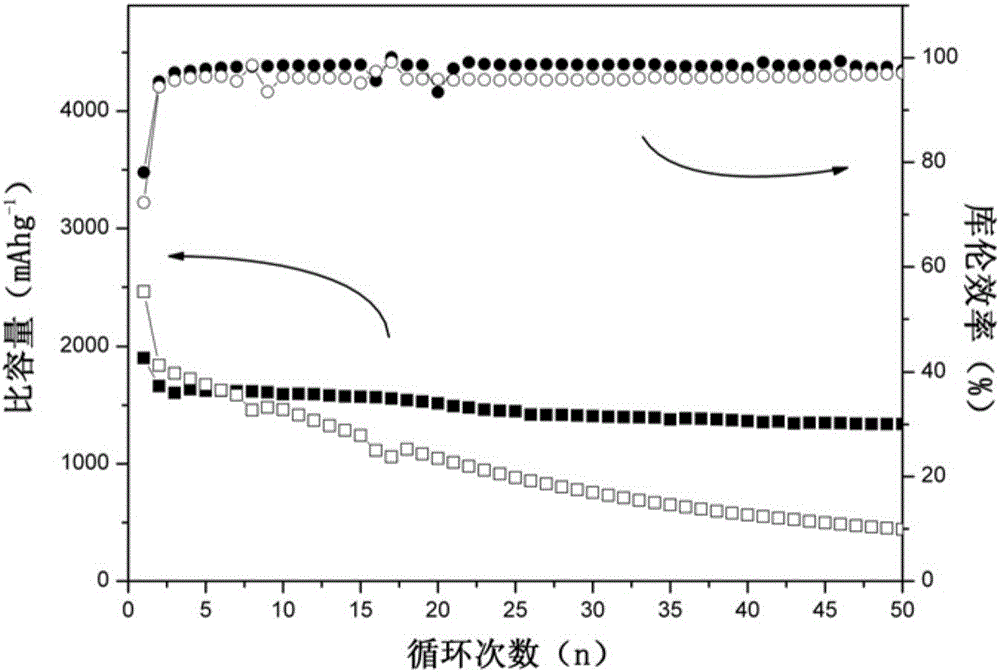

[0041] The porous silicon-carbon composite material prepared in this example was made into a button battery for performance testing, and the cycle specific capacity and Coulombic efficiency were compared with the porous silicon-carbon composite material prepared in the comparative example, as shown in image 3 shown. It can be seen from the figure that after 50 cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com