Production process of high-speed steel disc harrow

A production process, high-speed steel technology, applied in the direction of manufacturing tools, metal processing equipment, casting molding equipment, etc., can solve the problem of high cost, and achieve the effect of strong penetration into the soil and leveling the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

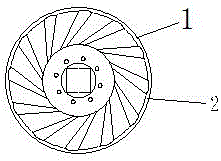

[0016] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0017] Such as figure 1 As shown, a production process of a high-speed steel disc harrow includes the following steps: smelting and pouring, remelting high-speed steel scrap heads, scrap knives and waste chips in an electric furnace; adding a certain amount to the circuit during the melting process amount of alloying elements; cast high-speed steel disc harrow casting adopts the method of high-temperature casting and low-temperature pouring. , Ti is added to the mold in advance to inoculate the high-speed steel to refine the dendrites.

[0018] Casting molds, sand casting and investment casting, or ceramic and metal casting;

[0019] Heat treatment, cast high-spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com