soil ripper for plowing

A ripper and soil-touching technology, which is applied to earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve the problems of reduced operating efficiency, tooth tip stress concentration, and low operating efficiency. Achieve the effects of prolonging life, dispersing soil pressure, and reducing soil contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The ripper for plowing land of the present invention will be further described in conjunction with specific examples below, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

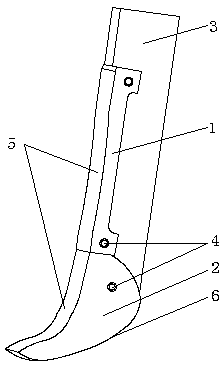

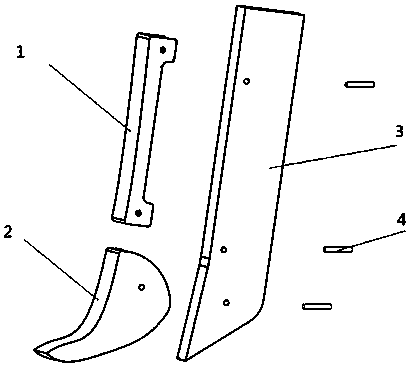

[0015] A ripper for plowing land, such as figure 1 As shown, it includes guard plate 1, tooth tip 2, support angle 3 and fixing pin 4. The tooth tip 2 is installed on the lower end of the support angle 3 through the fixing pin and constitutes the end of the soil, and the described guard plate 1 is fixed through the fixing pin Installed on the upper surface of the middle part of the contact surface of the support angle 3, the upper surface of the guard plate 1 and the tooth tip 2 together constitute the soil contact surface of the ripper, and the soil contact surface of the ripper is composed of the upper surface of the guard plate 1 and the upper and lower surfaces of the tooth tip 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com