High-strength nickel-base superalloy and manufacturing method thereof

A technology of nickel-based superalloy and manufacturing method, which is applied in the field of metal smelting, can solve the problems of reducing service performance and achieve the effects of improving medium temperature plasticity, reducing failure, matching high strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

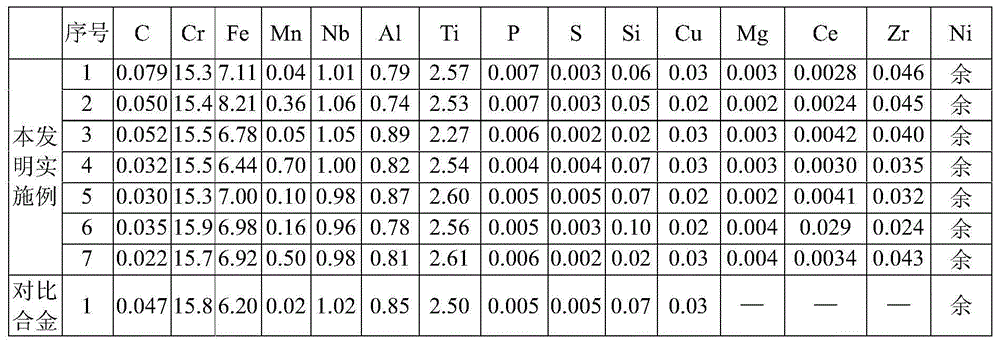

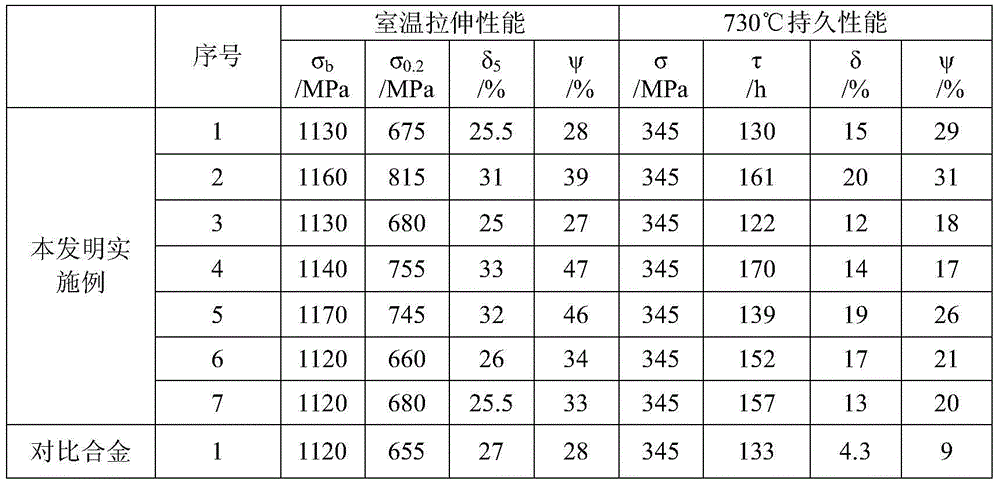

[0040] 1. According to the formula ingredients in Table 2, control C to be 0.079%, Cr to be 15.3%, Fe to be 7.11%, Mn to be 0.04%, Nb to be 1.01%, Al to be 0.79%, Ti to be 2.57%, and P to be 0.007% , S is 0.003%, Si is 0.06%, Cu is 0.03%, Mg is 0.003%, Ce is 0.0028%, Zr is 0.046%, and the balance is nickel and unavoidable impurities.

[0041] 2. Through vacuum induction melting and casting into Φ290 electrodes, the electrodes are remelted with argon protection electroslag or vacuum self-consumption to obtain Φ400 steel ingots. Among them, the setting of remelting process parameters, such as melting speed, etc., is limited to the fact that no metallurgical segregation occurs in the final steel ingot or finished product.

[0042] 3. After the steel ingot is heated to 1100-1200 ° C for at least 2 hours, it is forged and opened, and the opened billet is 120 square billets. The starting forging temperature is: 1050~1150°C, the final forging temperature is ≥900°C, and air-cooled to...

Embodiment 2

[0046] 1. According to the formula ingredients in Table 2, control C to be 0.050%, Cr to be 15.4%, Fe to be 8.21%, Mn to be 0.36%, Nb to be 1.06%, Al to be 0.74%, Ti to be 2.53%, and P to be 0.007% , S is 0.003%, Si is 0.05%, Cu is 0.02%, Mg is 0.002%, Ce is 0.0024%, Zr is 0.045%, and the balance is nickel and unavoidable impurities.

[0047] 2. Through vacuum induction melting and casting into Φ290 electrodes, the electrodes are remelted with argon protection electroslag or vacuum self-consumption to obtain Φ400 steel ingots. Among them, the setting of remelting process parameters, such as melting speed, etc., is limited to the fact that no metallurgical segregation occurs in the final steel ingot or finished product.

[0048] 3. After the steel ingot is heated to 1100-1200°C for a sufficient time, it is forged and billeted, and the billet is 120 square billets. The starting forging temperature is: 1050~1150°C, the final forging temperature is ≥900°C, and air-cooled to room ...

Embodiment 3

[0052] 1. According to the formula ingredients in Table 2, control C to be 0.052%, Cr to be 15.5%, Fe to be 6.78%, Mn to be 0.05%, Nb to be 1.05%, Al to be 0.89%, Ti to be 2.27%, and P to be 0.006% , S is 0.002%, Si is 0.02%, Cu is 0.03%, Mg is 0.003%, Ce is 0.0042%, Zr is 0.040%, and the balance is nickel and unavoidable impurities.

[0053] 2. Through vacuum induction melting and casting into Φ290 electrodes, the electrodes are remelted with argon protection electroslag or vacuum self-consumption to obtain Φ400 steel ingots. Among them, the setting of remelting process parameters, such as melting speed, etc., is limited to the fact that no metallurgical segregation occurs in the final steel ingot or finished product.

[0054] 3. After the steel ingot is heated to 1100-1200 ° C for at least 2 hours, it is forged and opened, and the opened billet is 120 square billets. The starting forging temperature is: 1050~1150°C, the final forging temperature is ≥900°C, and air-cooled to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com