Photo-initiation type polycarboxylic acid water reducing agent and preparation method thereof

A type of polycarboxylic acid and photoinitiator technology, applied in the field of photoinitiated polycarboxylate water reducer and its preparation, can solve the problems of complex production process, long reaction time, low production efficiency, etc., and achieve simple production process, Short reaction time and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

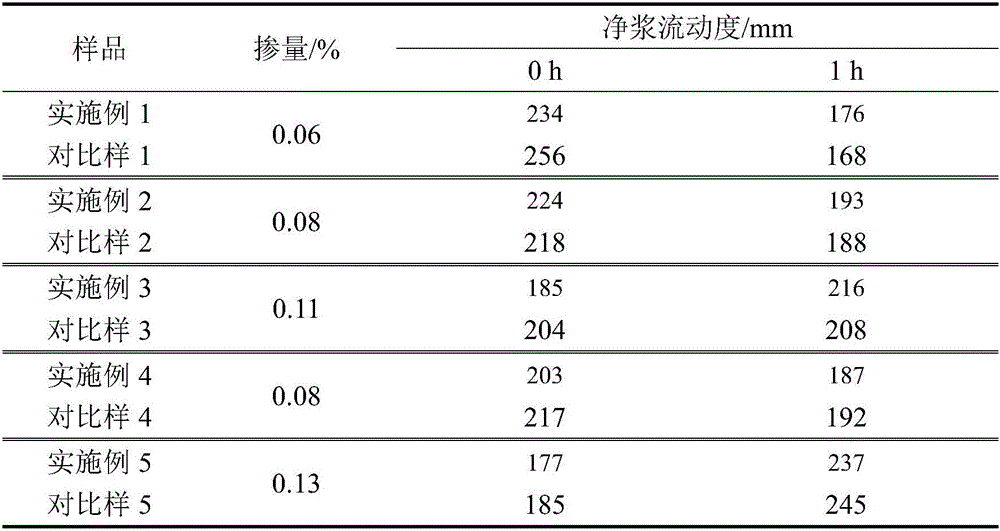

Examples

Embodiment 1

[0024] Isopentenol polyoxyethylene ether (molecular weight 2400): 85 parts

[0025] Acrylic: 13 parts

[0026] Mercaptopropionic acid: 0.6 parts

[0027] Photoinitiator-2959: 0.7 parts

[0028] Deionized water: 60 parts

[0029] At room temperature, add water, isopentenol polyoxyethylene ether, acrylic acid, mercaptopropionic acid, and photoinitiator-2959 into the photoinitiator reaction kettle, stir to dissolve, and mix well; turn on the ultraviolet light, and the light frequency is 275 -350nm continuous change, light intensity 15mj / cm 2 , irradiated for 5 minutes, aged for 1 hour, and neutralized by adding sodium hydroxide to pH=6.5, which is the product with a mass concentration of 60%.

[0030] Comparative sample 1

[0031] Isopentenol polyoxyethylene ether (molecular weight 2400): 85 parts

[0032] Acrylic: 13 parts

[0033] Mercaptopropionic acid: 0.6 parts

[0034] Hydrogen peroxide: 0.84 parts

[0035] Vitamin C: 0.25 parts

[0036] Deionized water: 60 parts ...

Embodiment 2

[0039] Allyl polyoxyethylene ether (molecular weight 1200): 72 parts

[0040] Acrylic: 15 parts

[0041] Maleic anhydride: 12 parts

[0042] Thioglycolic acid: 0.7 parts

[0043] Photoinitiator-QTX: 0.4 parts

[0044] Deionized water: 35 parts

[0045] At room temperature, add deionized water, allyl polyoxyethylene ether, acrylic acid, maleic anhydride, thioglycolic acid, and photoinitiator-QTX into the photoinitiation reactor, stir to dissolve, and mix well; turn on the UV lamp Irradiation, the light frequency changes continuously at 200-400nm, 20mj / cm 2 , irradiated for 4 minutes, aged for 2 hours, and neutralized by adding potassium hydroxide to pH = 7, which is the product with a mass concentration of 70%.

[0046] Comparative sample 2

[0047] Allyl polyoxyethylene ether (molecular weight 1200): 70 parts

[0048] Acrylic: 15 parts

[0049] Maleic anhydride: 12 parts

[0050] Thioglycolic acid: 0.7 parts

[0051] Hydrogen peroxide: 1.1 parts

[0052] Vitamin C: ...

Embodiment 3

[0056] Methallyl polyoxyethylene ether (molecular weight 2900): 80

[0057] Methacrylic acid: 8

[0058] Hydroxyethyl Acrylate: 12

[0059] Mercaptopropionic acid: 0.4

[0060] Photoinitiator-HBP:0.6

[0061] Deionized water: 100

[0062] At 5°C, add deionized water, methallyl polyoxyethylene ether, methacrylic acid, hydroxyethyl acrylate, mercaptopropionic acid, and photoinitiator-HBP into the photoinitiation reactor, stir to dissolve, and mix Uniform; turn on the UV lamp irradiation, the light frequency changes continuously at 350-550nm, 12mj / cm 2 , irradiated for 8 minutes, aged for 0.5 hours, and neutralized by adding sodium hydroxide to pH=7.5, which is the product, and its mass concentration is 50%.

[0063] Comparative sample 3

[0064] Methallyl polyoxyethylene ether (molecular weight 2900): 80

[0065] Methacrylic acid: 8

[0066] Hydroxyethyl Acrylate: 12

[0067] Mercaptopropionic acid: 0.4

[0068] Hydrogen peroxide: 0.4 parts

[0069] Vitamin C: 0.12 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com