Copper painting sintering process

A technology, copper-zinc technology, applied in the field of metal surface pattern processing, can solve the problems of unreachable relationship between supply and demand of cost, pay a high price, increase environmental pollution and other problems, and achieve the effect of pure color, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment the present invention is described in further detail:

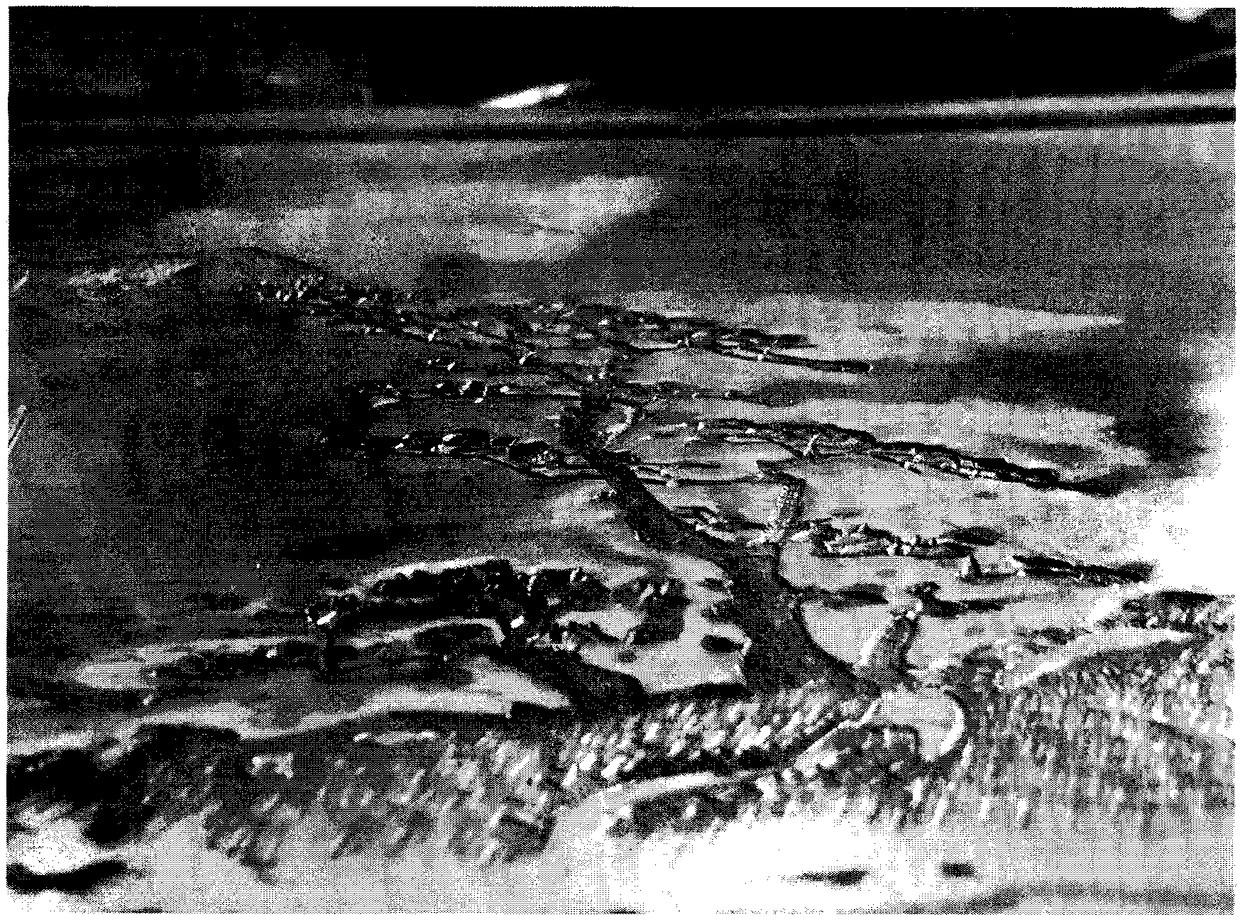

[0020] Copper painting sintering first needs to chisel or chisel the pattern concave pattern on the copper vessel ( figure 1 ); 60% red copper plus 40% zinc is melted and cast into a piece of copper alloy, and then forged into zinc alloy powder through countless times ( figure 2 ), copper-zinc alloy powder ( figure 2 ) and brazing powder ( image 3 ) according to the ratio of 1:1, add appropriate amount of water, heat and stir to make paste copper-zinc alloy powder blending agent ( Figure 4 ), the smearing operation of the blender ( Figure 5 ), it is necessary to accurately and slowly apply the blending agent to the indentations of the entire pattern ( figure 1 ); then put the copper utensil on the electric furnace, heat it evenly to 850 degrees Celsius, and keep it heated at a constant temperature of 850 degrees Celsius, and heat the pattern part at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com