Composite material for automobile wheel cover

A composite material and wheel cover technology, which is applied to vehicle parts, synthetic resin layered products, transportation and packaging, etc., can solve problems such as poor sound insulation effect and low sound transmission loss of wheel covers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

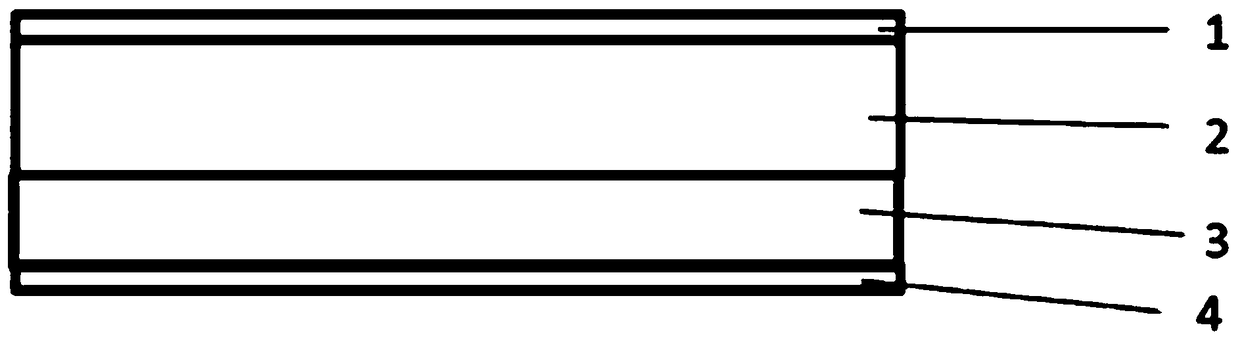

[0029] An automobile wheel cover composite material, comprising a first non-woven fabric layer 1, a sound-absorbing cotton layer 2, a polymer resin combined sheet layer 3 and a second non-woven fabric layer 4 sequentially laminated from top to bottom;

[0030] The polymer resin composite sheet layer 3 is composed of three layers with a thickness of 1.2-1.3mm and a density of 1.5-1.6g / mm 3 EVA 1 Sheet, thickness 0.8~0.9mm, density 1.3~1.4g / mm 3 EVA 2 Sheet, thickness 1.3~1.4mm, density 1.7~1.8g / mm 3 EVA 3 laminated sheets;

[0031] The first non-woven fabric layer 1 is a PET non-woven fabric with a weight of 20g / m 2 ;

[0032] The sound-absorbing cotton layer 2 is PP / PET two-component fiber cotton with a fiber fineness of 0.3-30 denier and a weight of 400g / m 2 ;

[0033] The second non-woven fabric layer 4 is a PET non-woven fabric, and the weight is 40g / m 2 ;

[0034] The first non-woven fabric layer 1, the sound-absorbing cotton layer 2, the polymer resin combined s...

Embodiment 2

[0036] An automobile wheel cover composite material, comprising a first non-woven fabric layer 1, a sound-absorbing cotton layer 2, a polymer resin combined sheet layer 3 and a second non-woven fabric layer 4 sequentially laminated from top to bottom;

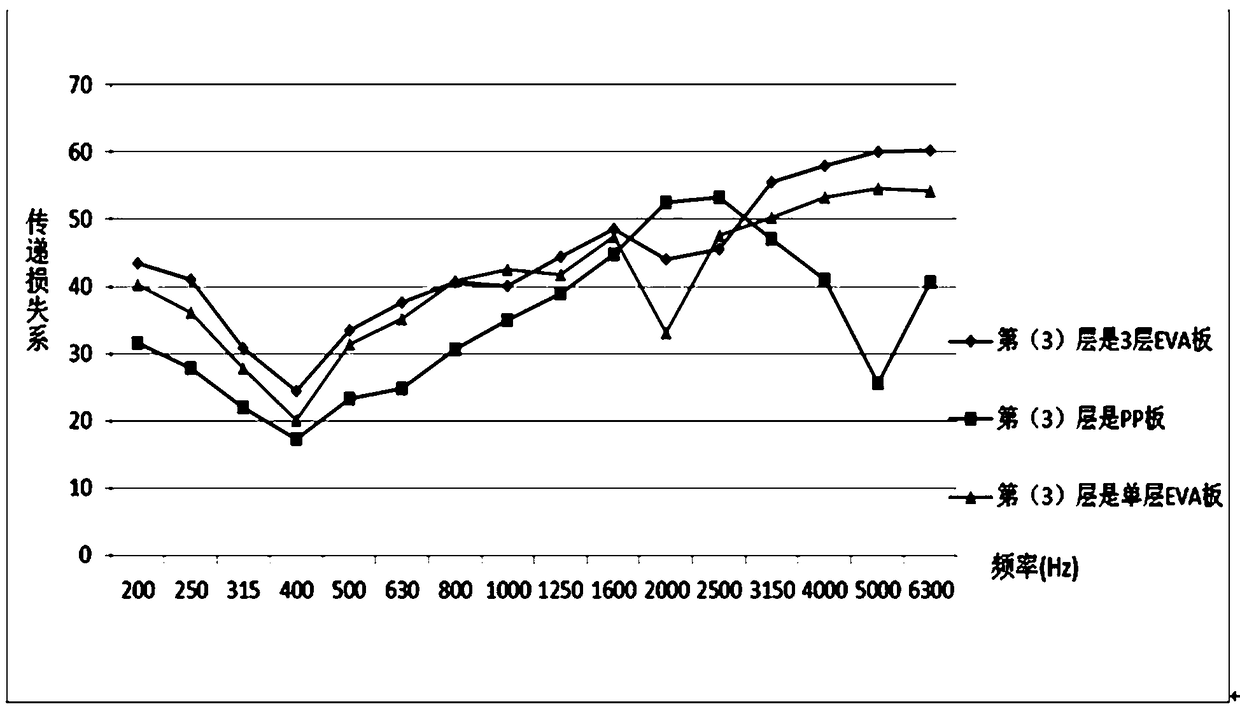

[0037] The polymer resin composite sheet layer 3 is composed of three layers with a thickness of 1.1-1.2mm and a density of 1.0-1.1g / mm 3 PP sheet with a thickness of 1.2-1.3mm and a density of 1.5-1.6g / mm 3 EVA 1 Sheet, thickness 1.0~1.1mm, density 1.3~1.4g / mm 3 EVA 2 Sheets are laminated; other are the same as embodiment 1; the average transmission loss coefficient of the obtained automobile wheel cover composite material is 40db, and high sound reflectivity is arranged in the medium and high frequency range, and there is no obvious sound transmission loss trough to occur, and It effectively solves the problems of stone impact and water impact when the car is running at high speed.

Embodiment 3

[0039] An automobile wheel cover composite material, comprising a first non-woven fabric layer 1, a sound-absorbing cotton layer 2, a polymer resin combined sheet layer 3 and a second non-woven fabric layer 4 sequentially laminated from top to bottom;

[0040] The polymer resin combined sheet layer 3 is composed of three layers with a thickness of 1.2-1.3mm and a density of 1.4-1.5g / mm 3 PET sheet with a thickness of 1.2-1.3mm and a density of 1.5-1.6g / mm 3 EVA 1 Sheet, thickness 0.8~0.9mm, density 1.3~1.4g / mm 3 EVA 2 Sheets are superimposed; others are the same as in Example 1; the average transmission loss coefficient of the obtained automobile wheel cover composite material is 42db, and there is no obvious sound transmission loss trough in the middle and high frequency ranges, and effectively solves the problem of high-speed driving of automobiles. The problem of rock and water hammer during the time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com