Heavy metal ion adsorption film and preparation method thereof

A technology for heavy metal ions and adsorption membranes, applied in alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of poor uniformity, instability, and damage to the membrane structure of membrane adsorbents, and expand the adsorption surface area , Promote adhesion tendency, enhance the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

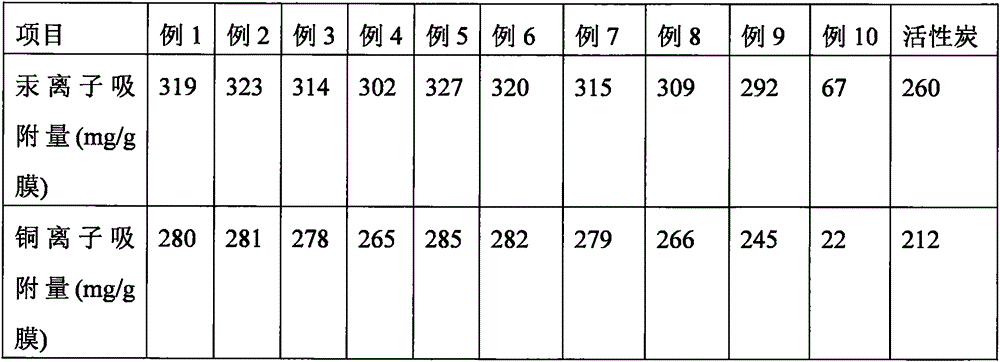

Examples

preparation example Construction

[0035] A preparation method for a heavy metal ion adsorption membrane, comprising the steps of:

[0036] S100 Disperse the metal organic framework material in the corresponding weight part in the solvent A, add the modifying agent under stirring, raise the temperature to 60°C, continue stirring for 1-5 hours, and add the stabilizer to form a dispersion liquid;

[0037] S200 dissolving 2-mercaptobenzimidazole in solvent B, adding the obtained solution into the dispersion liquid, and continuing to stir at 60°C for 1 to 6 hours to obtain a casting solution;

[0038]S300 filtering the casting solution and standing for defoaming for 1 to 2 hours, casting it on a glass plate, and drying it in an oven; and

[0039] S400 is heat-treated at 110-120°C for 1-5 hours, then placed in 2mol / L sulfuric acid for 10-24 hours, then rinsed with water until the washing liquid is neutral, and then put the wet film under vacuum at 50-60°C The metal-organic framework material composite film immobili...

Embodiment 1

[0052] (1) Preparation of metal organic framework materials

[0053] The preparation of metal-organic framework material MIL-100 includes the steps of: dissolving 2.7g of ferric chloride hexahydrate in 50mL of deionized water, stirring to fully dissolve, then adding 1.39g of trimesic acid, and continuing to stir for 0.5h. Finally, the above solution was put into an autoclave to react at 130°C for 72h. After the reaction was completed, it was cooled to room temperature, washed three times with hot water and methanol, boiled in boiling methanol for 12 hours, and vacuum-dried at 150° C. for 12 hours to obtain a metal-organic framework material.

[0054] (2) Preparation of Heavy Metal Ion Adsorption Membrane

[0055] Weigh 30 parts of metal organic framework materials and disperse them in 60 parts of dimethylformamide, add 3 parts of sodium lauryl sulfate under stirring, raise the temperature to 60°C, continue stirring for 1 hour, add 2 parts of phosphate buffer to form a dispers...

Embodiment 2

[0060] The composition in parts by weight of each component is as follows. The preparation method and performance test of the adsorption film are the same as in Example 1, and the main performance indicators are shown in Table 1. MIL-100 is 20 parts, 2-mercaptobenzimidazole is 5 parts, modifier sodium lauryl sulfate is 3 parts, stabilizer phosphate buffer is 2 parts, solvent A dimethylamide is 60 parts, Solvent B ethanol is 5 parts. The conditions are that the mass ratio of metal organic framework material to 2-mercaptobenzimidazole is 4:1, and the mass ratio of solvent A to solvent B is 12:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com