Ultraphonic spray tower with low-placed dilution device

A technology of diluter and spray tower, which is applied in the field of dry suction dilution device in sulfuric acid, can solve the problems of simple diluter structure, low acid gas efficiency, uneven dilution, etc., achieve good economic benefits, improve gas absorption rate, simplify The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

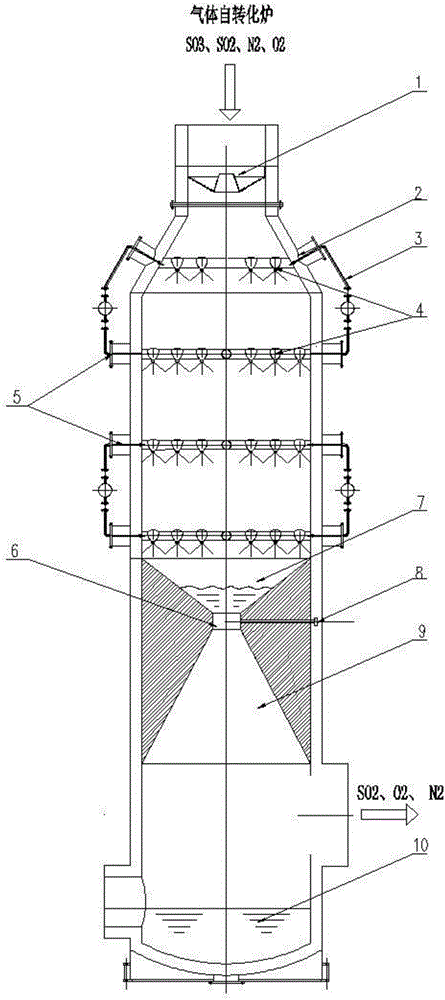

[0018] In order to express the patent of the present invention more clearly, combined with the diluter low ultrasonic spray tower attached figure 1 The patent of the present invention is described further.

[0019] A low-set ultrasonic spray tower for a diluter, consisting of a gas distributor 1, a spray pipe 2, a circulating acid pipe 3, an ultrasonic nozzle 4, a circulating acid nozzle 5, a dilution chamber 6, a sedimentation tank 7, a dilution water pipe 8, and an expansion chamber 9. Dilute acid tank 10 and other components.

[0020] Gas distributor 1 is arranged at the top of the tower, SO 3 The gas diffuses into the absorption tower through the gas distributor. The tower body is provided with a spray pipe 2, and the outside of the tower body is fixedly connected with a circulating acid pipe 3, and the circulating acid pipe is connected with the spray pipe through a circulating acid nozzle 5.

[0021] The spray pipe 2 is arranged vertically by two spray main pipes, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com