Fuel metering unit for a high-pressure injection system

A technology of fuel dosing and components, applied in the direction of low-pressure fuel injection, low-pressure fuel injection, charging system, etc., which can solve the problems of troublesome and expensive manufacturing of fuel dosing units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

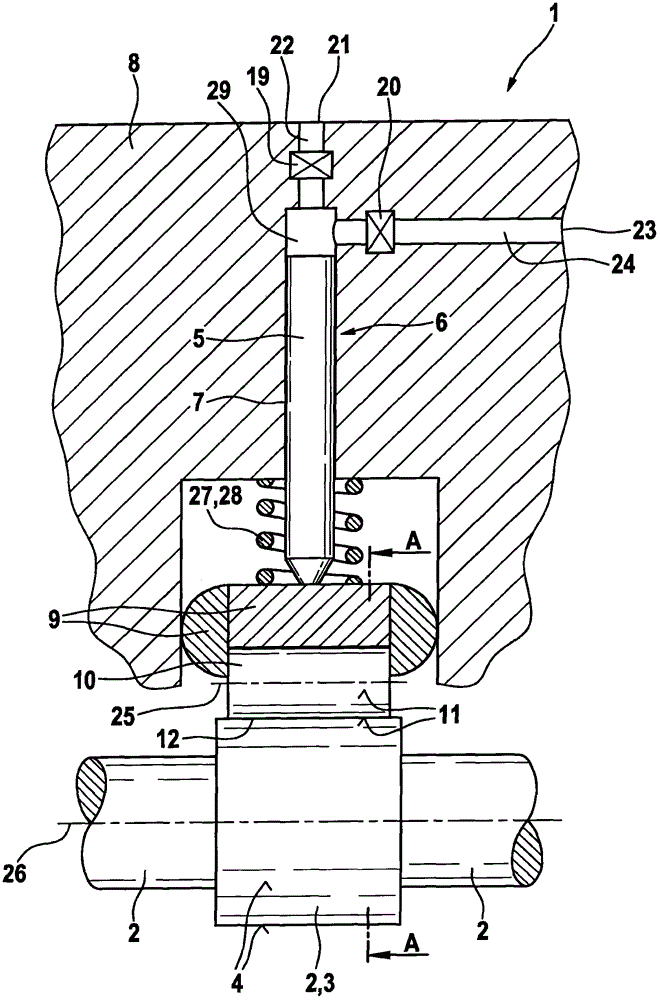

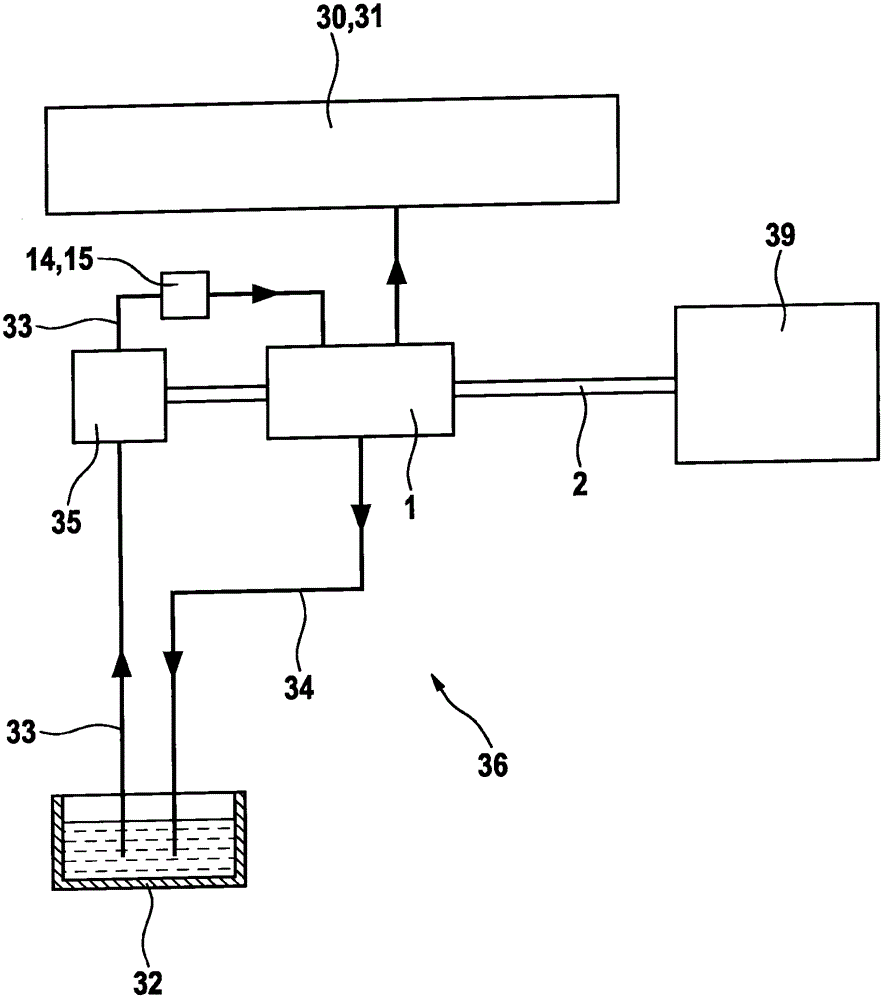

[0033] exist figure 1 shows a cross-section through a high-pressure pump 1 for delivering fuel. The high-pressure pump 1 serves to deliver fuel, such as diesel or gasoline, to the internal combustion engine 39 at high pressure. The pressure that can be generated by the high-pressure pump 1 is, for example, in the range between 1000 and 3000 bar.

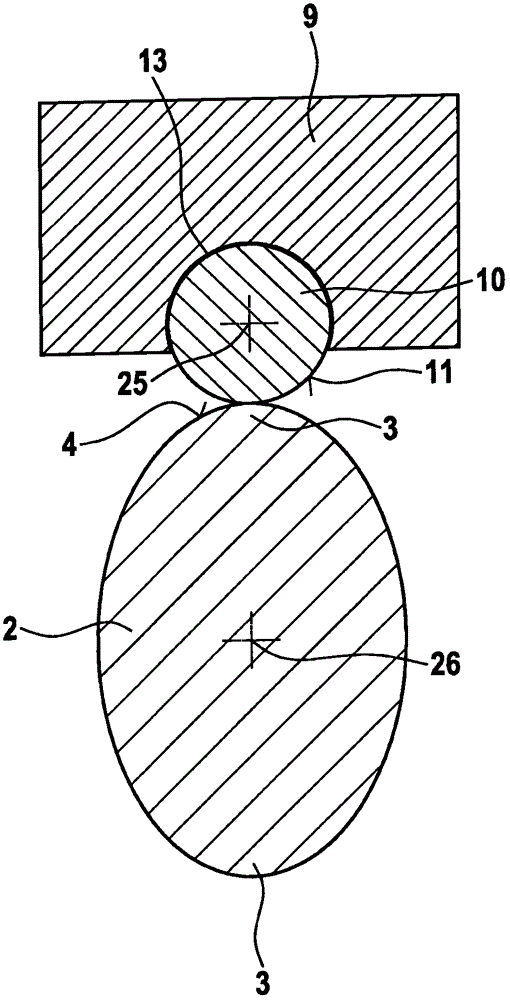

[0034] The high-pressure pump 1 has a drive shaft 2 with two cams 3 , which executes a rotational movement about an axis of rotation 26 . The axis of rotation 26 is located at figure 1 in the plane of the graph and perpendicular to figure 2figure plane. The piston 5 is mounted in a cylinder 6 which is formed by a housing 8 . A working chamber 29 is delimited by the cylinder 6 , the housing 8 and the piston 5 . An inlet channel 22 with inlet valve 19 and an outlet channel 24 with outlet valve 20 open into a working chamber 29 . The fuel flows through the inlet channel 22 into the working chamber 29 and the fuel under high pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com