Switch tube control pulse driving method

A technology for controlling pulses and driving methods, applied in the direction of output power conversion devices, electrical components, etc., can solve problems such as difficult high frequency, high power density power converter design, pulse transformer saturation, drive circuit complexity, etc., to achieve common Strong mode interference suppression ability, high dielectric strength, and the effect of eliminating duty cycle restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

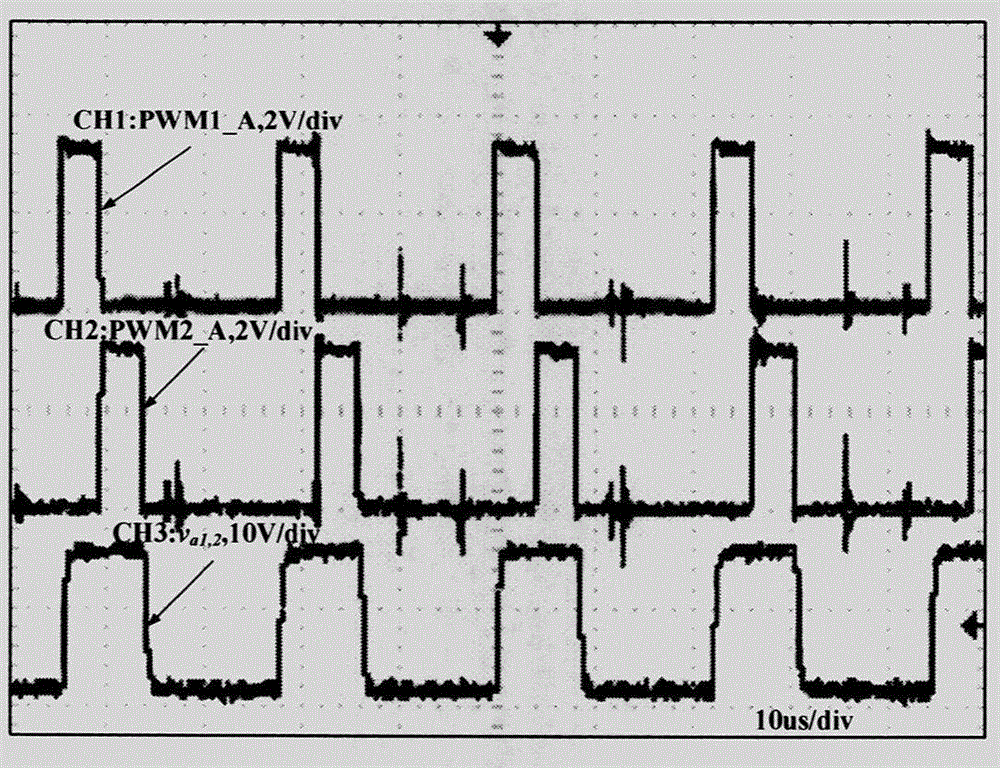

[0037] Aiming at the magnetic saturation characteristics of the pulse transformer in the traditional electromagnetic isolation, the duty cycle of the general transmission is limited within 50%, and the minimum duty cycle of the drive signal is also limited by the magnetizing current, and proposes a high A new driving method of frequency modulation.

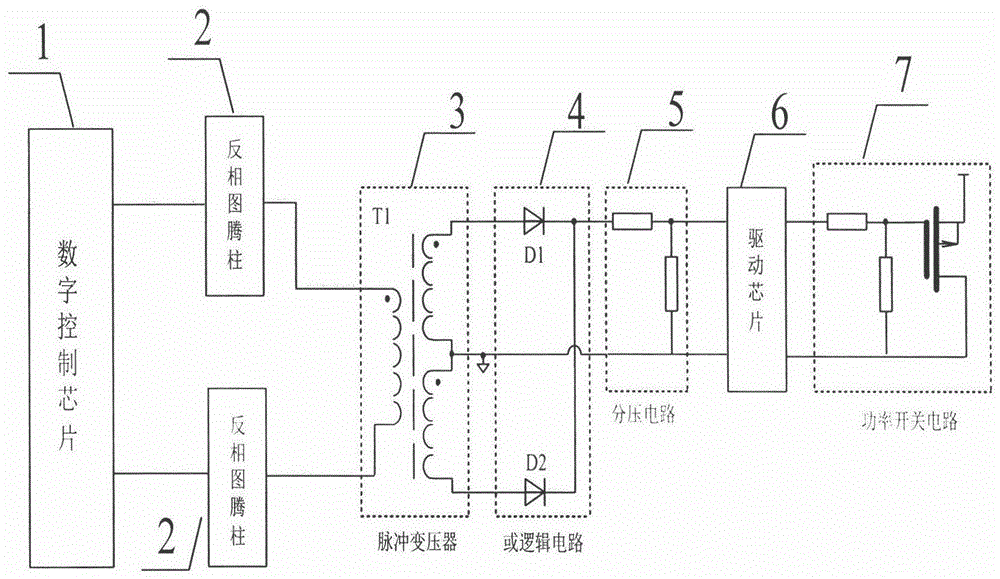

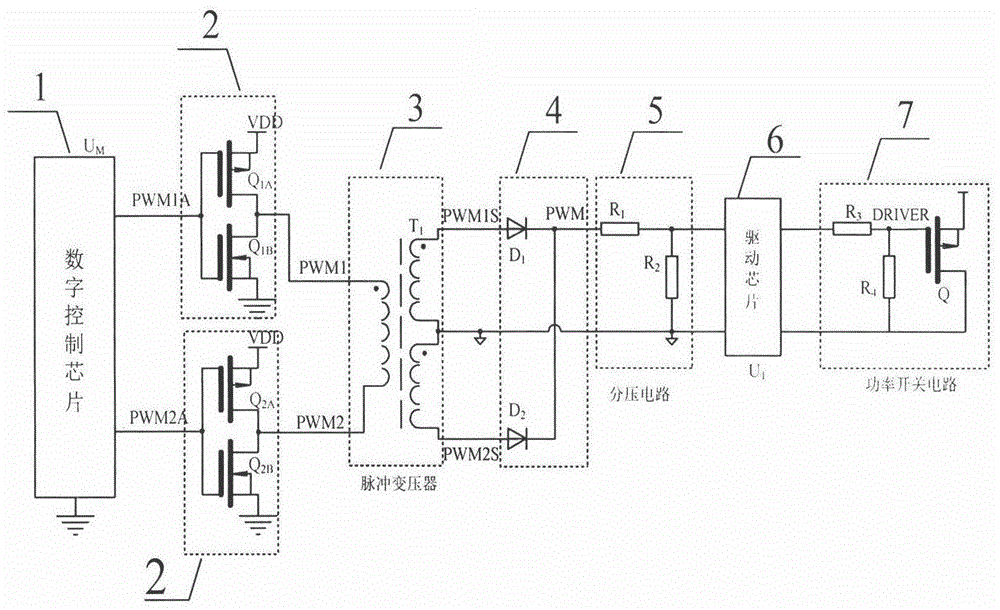

[0038] Such as figure 1 , figure 2 Shown:

[0039] Parts of the present invention constitute:

[0040] Digital control chip 1, inversion totem pole 2, pulse transformer 3, or logic circuit 4, voltage divider circuit 5, driver chip 6, power switch circuit 7.

[0041] The digital control chip 1 divides the target pulse control signal into two control signals PWM1_A and PWM2_A with equal pulse width. PWM1_A and PWM2_A are respectively connected to the inverting totem pole 2, and then respectively connected to the primary winding of the pulse transformer 3 through the inverting totem pole 2. The two ends of the pulse transformer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com