High-performance oxygen reduction catalyst MnOx/Mn2N-N-C composite catalyst and preparation method and application thereof

A composite catalyst and high-performance technology, applied in the field of electrocatalysis, can solve the problems of low activity and conductivity, and achieve the effects of simple preparation method, good comprehensive performance and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] MnO x / Mn 2 Preparation of N-N-C:

[0030] The synthetic method of one-step heat treatment is adopted, and the specific process is as follows: Weigh 0.3g of glucose, 10g of urea and 0.08g of manganese acetate tetrahydrate, add 5mL of deionized water, and after ultrasonic dissolution and evaporation of water, the obtained precursor mixture is Heating from room temperature to 900°C in nitrogen protective gas at a heating rate of 4°C / min, keeping at 900°C for 1 hour, cooling naturally to 70°C, taking out, and then cooling to room temperature in air to obtain a black powder. MnO x Nanoparticles (MnO and Mn 3 o 4 ) and Mn 2 The mass percentage content of N nanoparticles is about 31%, the mass percentage content of nitrogen-doped graphene is about 69%, and the mass percentage content of nitrogen in nitrogen-doped graphene is about 1.5%.

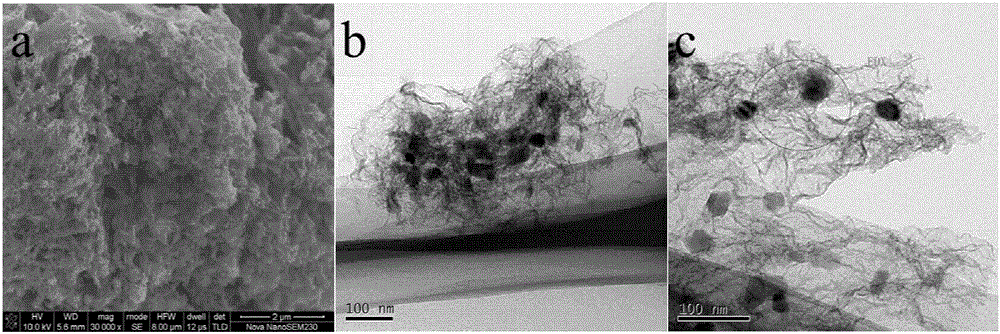

[0031] X-ray diffractometer (XRD, Rigaku-D / Max2550, Cu-Kα, 40kV, 300mA) for phase analysis of the product; the morphology of the pr...

Embodiment 2

[0035] According to the method of embodiment 1, add 0.1g manganese acetate tetrahydrate in the precursor, prepare MnO x / Mn 2 N-N-C-2 complex.

[0036] The evaluation method of catalytic performance is the same as in Example 1.

[0037] MnO x / Mn 2 The onset potential of N-N-C-2 composite as an ORR catalyst is -0.09V (vs.Hg / HgO), the half-wave potential is -0.24V (vs.Hg / HgO), and the limiting current density is -5.1mA / cm 2 . In the current meter evaluation, after 7200s of continuous operation, the current density retention rate is about 93%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com