Sulfur-doping porous carbon material of sodium ion battery and preparation method of sulfur-doping porous carbon material

A sodium-ion battery, porous carbon material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of large interlayer spacing, mismatched interlayer spacing, poor cycle stability, etc., and achieve low cost and physical and chemical stability. good, repeatable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] First weigh 1.25g of zinc nitrate and dissolve it fully in 100mL of methanol solution, then weigh 2.32g of dimethylimidazole and slowly add it to the above solution under magnetic stirring conditions, and then continue stirring at room temperature for 16h. In the centrifugation method, the white precipitate obtained from the reaction is repeatedly washed with methanol and deionized water, and then dried to obtain the precursor of the zinc-based metal organic framework material.

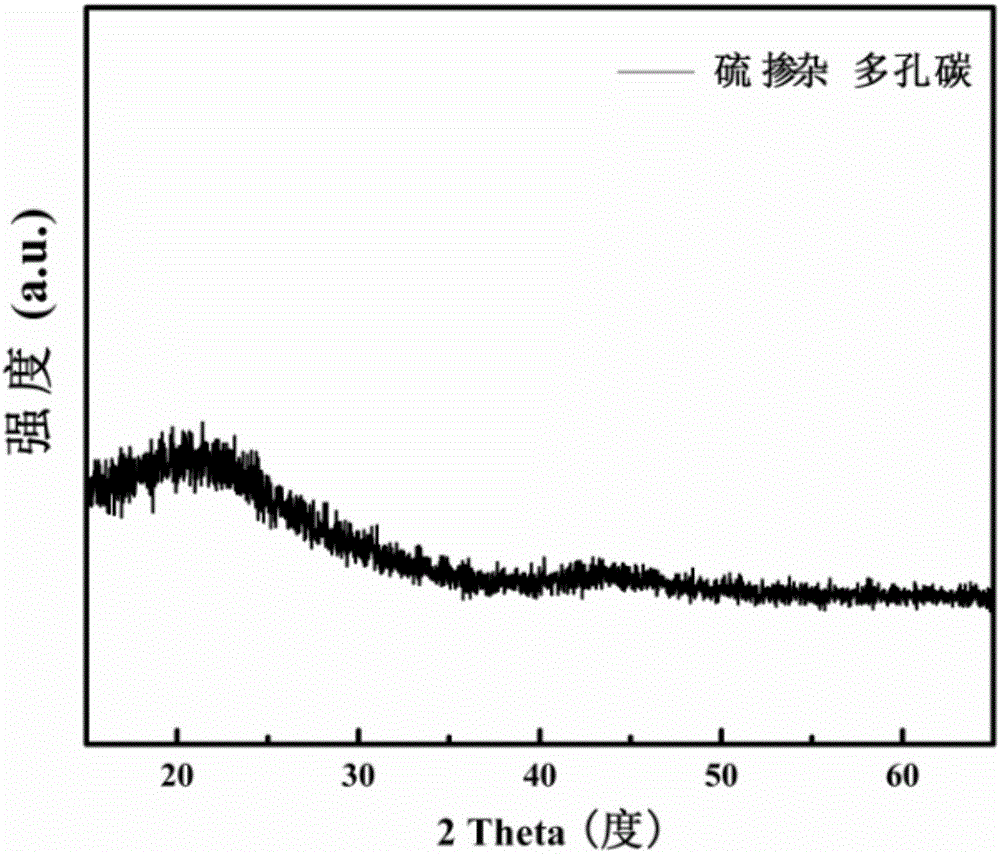

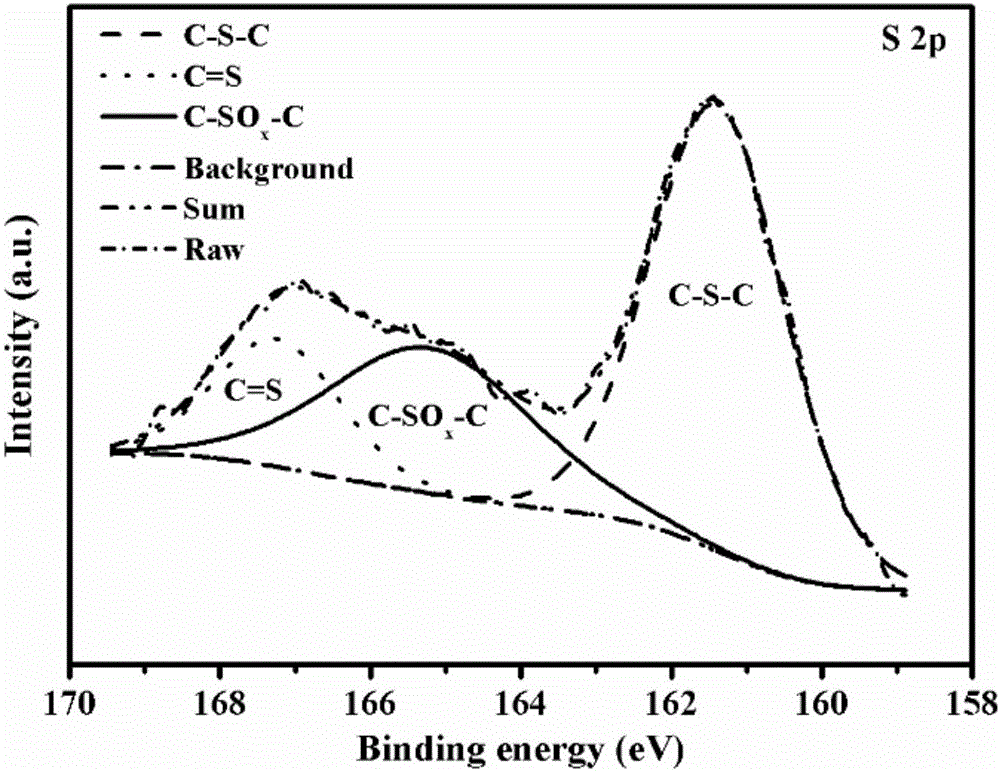

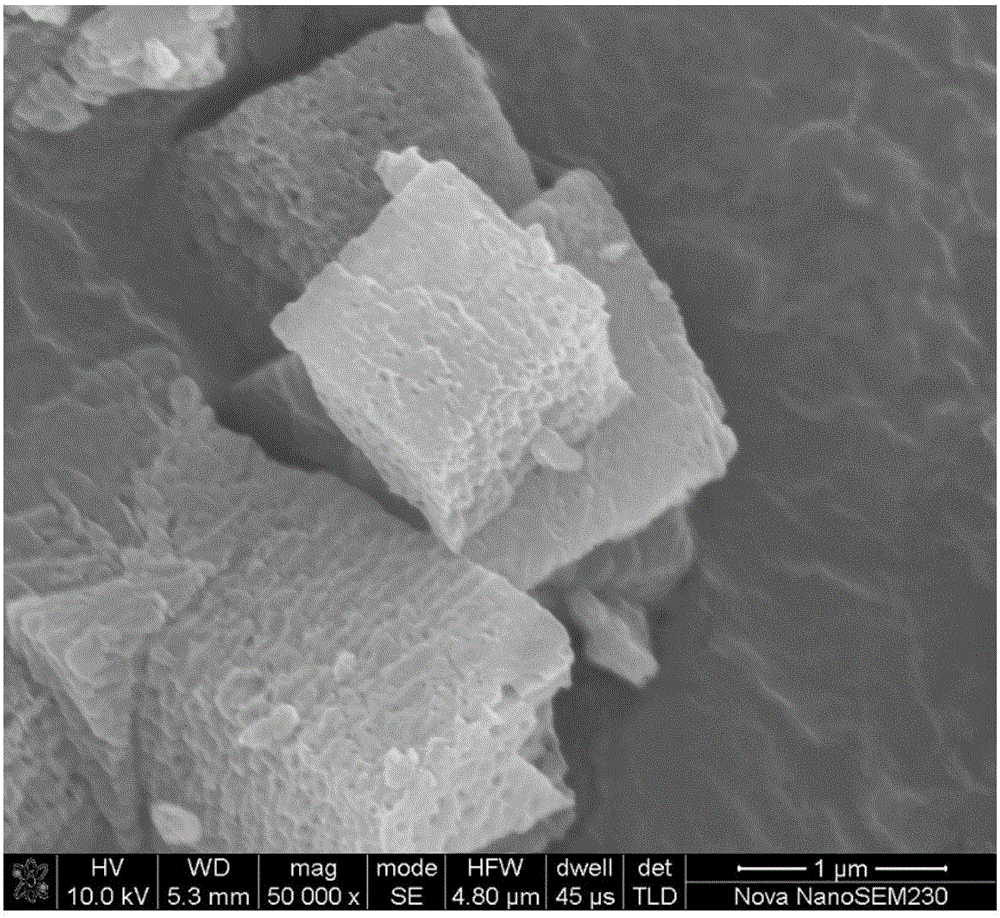

[0043] Weigh 0.1g of Zn-based metal-organic framework material and 0.1g of sublimated sulfur powder in a corundum mortar and grind them thoroughly, transfer the powder after the two are evenly mixed into a corundum porcelain boat and put it into a single-temperature zone vacuum tube furnace. Introduce argon gas at 155°C to fully diffuse the sulfur powder in the internal channel structure of the metal-organic framework material. After the reaction was carried out for 3 hours, the tube furnace was...

Embodiment 2

[0051] First weigh 1.25g of zinc nitrate and dissolve it fully in 100mL of methanol solution, then weigh 2.32g of dimethylimidazole and slowly add it to the above solution under magnetic stirring conditions, and then continue stirring at room temperature for 16h. In the centrifugation method, the white precipitate obtained from the reaction is repeatedly washed with methanol and deionized water, and then dried to obtain the precursor of the zinc-based metal organic framework material.

[0052] Weigh 0.1g zinc-based metal-organic framework material and 0.05g sublimated sulfur powder and grind them fully in a corundum mortar, transfer the powder after the two are evenly mixed into a corundum porcelain boat and put it into a single-temperature zone vacuum tube furnace. Introduce argon gas at 155°C to fully diffuse the sulfur powder in the internal channel structure of the metal-organic framework material. After the reaction was carried out for 3 hours, the tube furnace was gradual...

Embodiment 3

[0055] First weigh 1.25g of zinc nitrate and dissolve it fully in 100mL of methanol solution, then weigh 1.45g of dimethylimidazole and slowly add it to the above solution under magnetic stirring conditions, and then continue stirring at room temperature for 16h. In the centrifugation method, the white precipitate obtained from the reaction is repeatedly washed with methanol and deionized water, and then dried to obtain the precursor of the zinc-based metal organic framework material.

[0056] Weigh 0.1g of Zn-based metal-organic framework material and 0.1g of sublimated sulfur powder in a corundum mortar and grind them thoroughly, transfer the powder after the two are evenly mixed into a corundum porcelain boat and put it into a single-temperature zone vacuum tube furnace. Introduce argon gas at 155°C to fully diffuse the sulfur powder in the internal channel structure of the metal-organic framework material. After the reaction was carried out for 3 hours, the tube furnace was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com