Method for co-producing humic acid containing water-soluble fertilizer by utilizing seaweed extract

A technology of seaweed extract and production method, which is applied in the direction of nitrate fertilizer, ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, etc., can solve the problems of long enzymatic hydrolysis time, destruction of active ingredients of seaweed, low extraction efficiency, etc., and achieve Improve crop stress resistance, increase compatibility, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

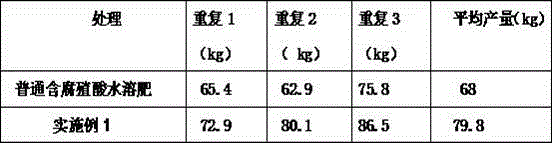

Examples

Embodiment 1

[0028] Add the washed fresh Enteromorpha enteromorpha into a reaction kettle filled with water and alcohol for beating. After beating, add sorbitan fatty acid ester-20 and alkylphenol polyoxyethylene ether as a wetting and penetrating agent, Fresh Enteromorpha, water, alcohol, alkylphenol polyoxyethylene ether, and sorbitan fatty acid ester-20 are in a mass ratio of 20:15:64.96:0.02:0.02, soaked at 20°C for 72 hours, and placed in a negative pressure of 0.5 Mpa, distill and recover part of the organic solvent at a temperature of 45°C. The filter press uses a 1000-mesh filter cloth for pressure filtration. The obtained filtrate, urea and potassium humate are mixed according to the mass ratio of 50:45:5, heated to 40°C and stirred to dissolve completely. Finally, spray drying, the product after drying is the product of the present invention.

Embodiment 2

[0030] Mix the washed dried kelp and dried Enteromorpha into dry seaweed in proportion, soak until the water content of fresh kelp is consistent with that of fresh kelp, add it to a reaction kettle filled with water, alcohol and ether, and beat together. Alkylphenol ethoxylates and polyoxyethylene sorbitan monolaurate-60 are added as wetting penetrating agents, soaked dried kelp, enteromorpha, water, alcohol, ether, alkylphenol polyoxyethylene The mass ratio between ether and polyoxyethylene sorbitan monolaurate-60 is 4:2:25:60.97:8:0.01:0.02, soaked at 25°C for 60 hours, under negative pressure 0.7Mpa, temperature 50 Part of the organic solvent is distilled and recovered at ℃, and the filter press uses a 1200-mesh filter cloth for pressure filtration. The obtained filtrate, urea, industrial grade ammonium dihydrogen phosphate, potassium humate and potassium fulvic acid are in a mass ratio of 65:20:10:3 : 2 mixed, after being heated to 45 ℃ of stirring and dissolving completel...

Embodiment 3

[0032] Add the washed fresh kelp into a reaction kettle filled with water, alcohol, ethyl acetate and ether for beating, and add sodium dodecylbenzenesulfonate and alkylphenol polystyrene as a wetting and penetrating agent after beating. Oxyethylene ether, sorbitan fatty acid ester-60 and simethicone oil, fresh kelp, water, alcohol, ethyl acetate, ether, sodium dodecylbenzenesulfonate, alkylphenol polyoxyethylene ether, lost Sorbitan fatty acid ester-60 and simethicone oil according to the mass ratio of 18:18:20:15:28.96:0.01:0.01:0.01:0.01, soak at 30°C for 46 hours, under negative pressure 1.0Mpa, temperature 55°C Part organic solvent is reclaimed under distillation, and the filter press adopts 1400 mesh filter cloths to carry out pressure filtration, and gained filtrate, urea, technical grade potassium dihydrogen phosphate, nitrohumic acid and sodium humate are according to mass ratio 60:25:10:2: 3. Mix, heat to 50°C, stir and dissolve completely, then spray dry, and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com