Two-dimensional titanate nanometer material and preparation method thereof

A nanomaterial, titanate technology, applied in the field of photocatalysis, can solve the problem of low light utilization rate, and achieve the effect of improving photocatalytic efficiency, large surface area, and not easy to curl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

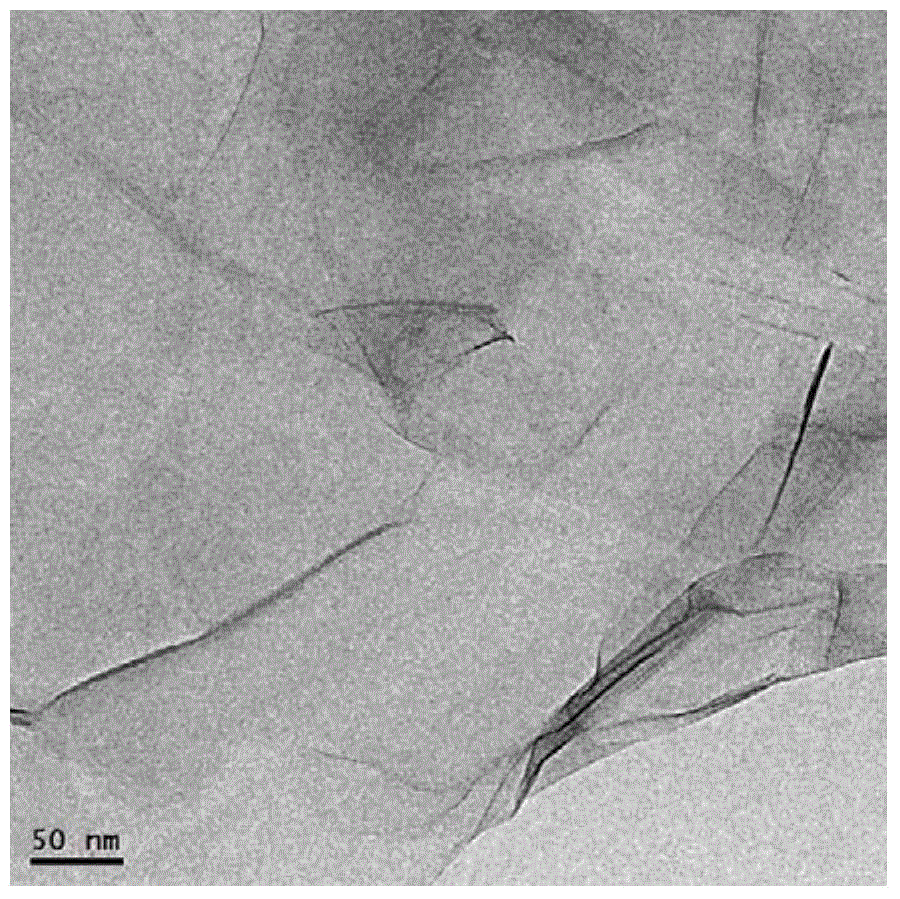

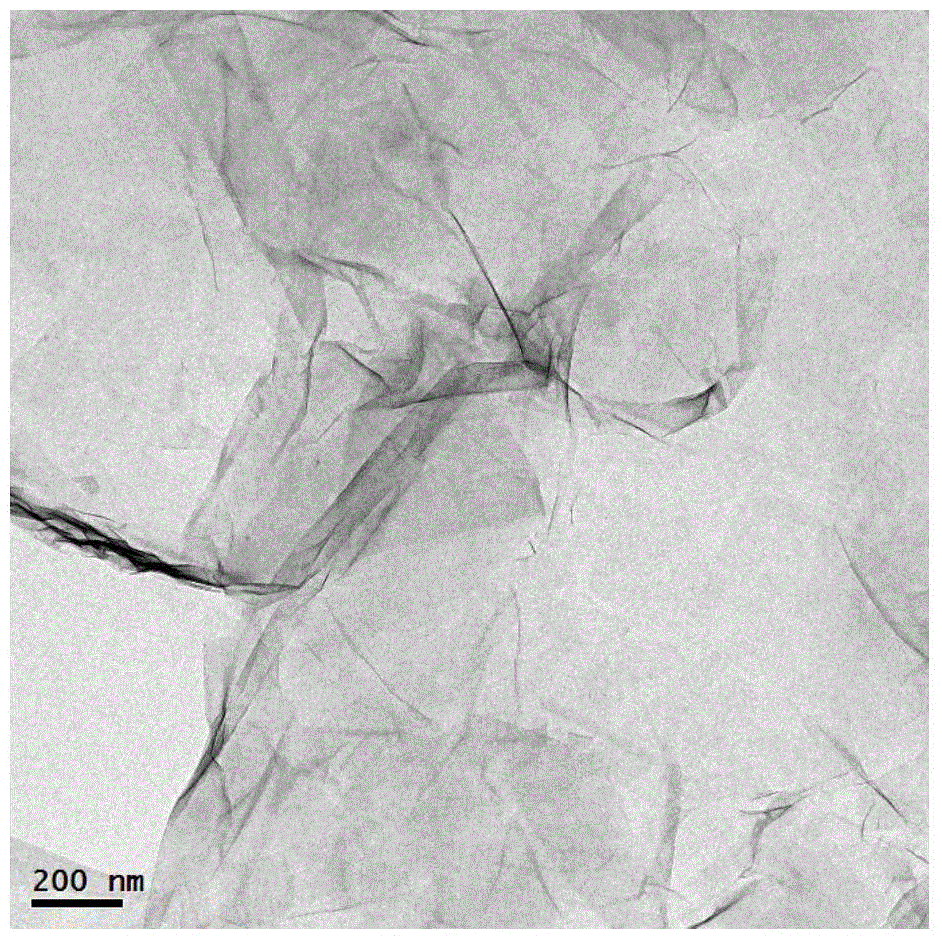

Image

Examples

preparation example Construction

[0030] In a preferred embodiment of the present invention, also provides a kind of preparation method of two-dimensional titanate nanomaterial, this preparation method comprises the following steps: with alkali metal carbonate and amorphous TiO 2 As a raw material, prepare protonated layered titanate; under heat treatment conditions, make protonated titanate contact with dichromate to form Cr-doped layered titanate; under stirring conditions, make the obtained The protonated layered titanate reacts with the organic amine in the liquid matrix to form the two-dimensional titanate nanomaterial by exfoliation.

[0031] In the above-mentioned method provided by the present invention, the Cr element doped in the titanate lattice of the prepared two-dimensional titanate nanomaterial is obtained by contacting and reacting protonated titanate and dichromate by means of heat treatment. , thereby enhancing the stability of the titanate lattice, and broadening the absorption bandwidth of ...

Embodiment 1

[0048] (1), the preparation method of two-dimensional titanate nanomaterials includes:

[0049] (1) by selecting sodium carbonate (analytical pure) and amorphous TiO 2 (analytical pure) is raw material, the two are mixed and ground by 1:5.3 molar ratio, form the mixed powder that average particle size is 400nm;

[0050] (2) calcining the mixed powder at 700°C for 40 hours to carry out high-temperature solid-state reaction to prepare layered titanate powder in advance;

[0051] (3) Add the layered titanate to a hydrochloric acid solution (analytical pure) with a concentration of 1mol / L and stir and pickle it for 15 hours. The amount of hydrochloric acid added to each gram of layered titanate is 75ml, and after pickling three times, the sample Washing to neutrality, drying and filtering to obtain protonated layered titanate;

[0052] (4) Add ammonium dichromate (the weight ratio of ammonium dichromate to protonated layered titanate is 0.6:1) to the dried protonated titanate, h...

Embodiment 2

[0070] (1), the preparation method of two-dimensional titanate nanomaterials includes:

[0071] (1) By selecting rubidium carbonate (analytical pure) and amorphous TiO 2 (analytical pure) is raw material, the two are mixed and ground by 1:3.3 molar ratio, form the mixed powder that average particle size is 400nm;

[0072](2) calcining the mixed powder at 1100° C. for 30 hours to carry out high-temperature solid-state reaction to prepare layered titanate powder in advance;

[0073] (3) Add the layered titanate to a hydrochloric acid solution (analytical pure) with a concentration of 1mol / L and stir and pickle it for 25 hours. The amount of hydrochloric acid added per gram of the layered titanate is 80ml. After pickling three times, the sample Washing to neutrality, drying and filtering to obtain protonated layered titanate;

[0074] (4) Add ammonium dichromate (the weight ratio of ammonium dichromate to the protonated layered titanate is 25:100) to the dried protonated titana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com