Method for growing single-layer and multi-layer transition metal sulfides through alternating injection of reactants

A technology of transition metal and alternating injection, applied in the preparation of sulfide/polysulfide, chemical instruments and methods, molybdenum sulfide, etc., to achieve the effect of simple and convenient operation, precise and controllable growth conditions, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

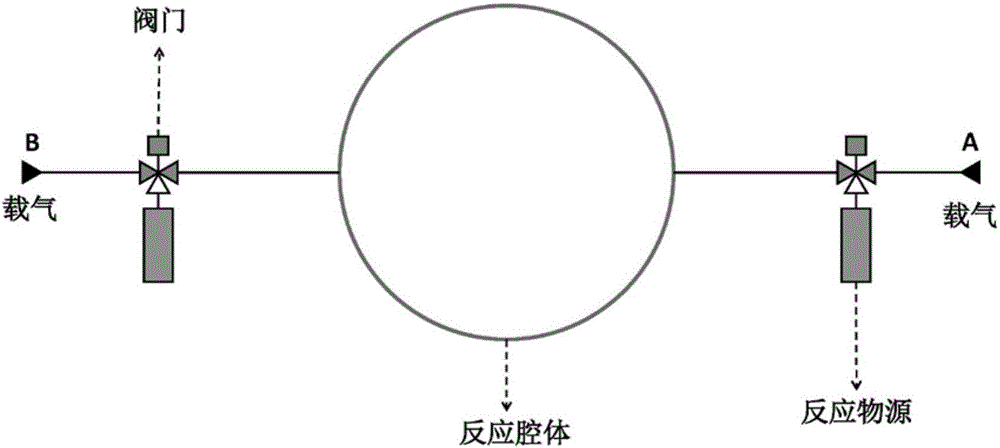

Method used

Image

Examples

Embodiment 1

[0011] Place a clean silicon substrate of 100 square centimeters in the deposition reaction chamber, control the reaction pressure at 5 mbar, and the reaction temperature at 700°C; set the flow rate of the carrier gas to 100 cubic centimeters per second, and alternately inject six The interval between molybdenum carbonyl and hydrogen sulfide, molybdenum hexacarbonyl and hydrogen sulfide was 3 minutes, and the interval between hydrogen sulfide and molybdenum hexacarbonyl was 1 minute. A total of 10 cycles were injected, and a single layer of molybdenum disulfide was deposited on the substrate.

Embodiment 2

[0013] Place a 1 square centimeter clean silicon wafer with a thin film of silicon dioxide in the deposition reaction chamber, control the reaction pressure at 15 mbar, and the reaction temperature at 100°C; set the flow rate of the carrier gas to 500 cubic centimeters per second, pass the carrier gas Molybdenum hexacarbonyl and diethyl sulfide are alternately injected into the cavity, the interval between molybdenum hexacarbonyl and diethyl sulfide is 10 minutes, and the interval between diethyl sulfide and molybdenum hexacarbonyl is 10 minutes. A total of 100 cycles are injected, and the deposition is obtained Multilayer molybdenum disulfide.

Embodiment 3

[0015] Put 21.3 square centimeters of clean layered mica in the deposition reaction chamber, control the reaction pressure at 20 mbar, and the reaction temperature at 300°C; set the flow rate of the carrier gas to 400 cubic centimeters per second, and alternately inject six The interval between tungsten carbonyl and hydrogen sulfide, tungsten hexacarbonyl and hydrogen sulfide is 30 seconds, and the interval between hydrogen sulfide and tungsten hexacarbonyl is 20 seconds. A total of 1000 cycles are injected, and multi-layer tungsten disulfide is deposited.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com