AlGaN heterojunction nano-pillar array light-emitting device and preparation method for the same

A technology of nano-pillar arrays and light-emitting devices, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of different chemical properties, poor flatness of AlGaN films, and high defect density, and achieves the effect of improving extraction efficiency and luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

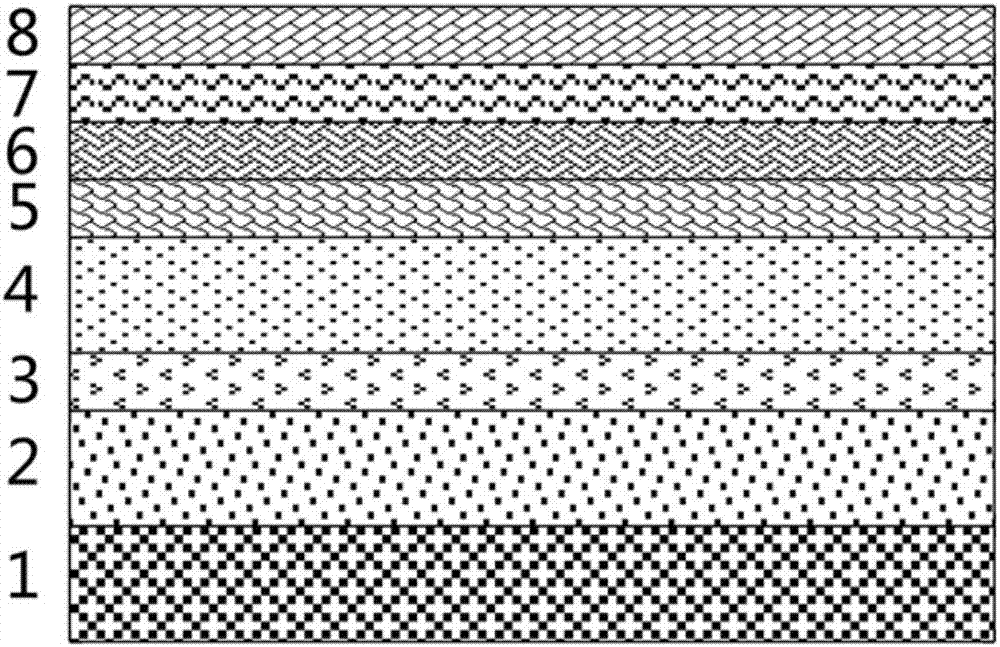

[0068] like Figure 1-10 Shown in, the preparation method of this AlGaN nanocolumn array structure, its step comprises:

[0069] 1) Select a GaN / AlN / AlGaN epitaxial substrate with x as 0.1, the thickness of the GaN buffer layer is 2μm, the thickness of the AlN insertion layer is 30nm, and the thickness of the AlGaN layer is 300nm-0.1μm, with acetone, isopropanol and deionized water After cleaning, dry it with high-purity nitrogen in a clean room, and grow a layer of high-temperature SiO on its surface by plasma-enhanced chemical vapor deposition. 2 layer with a thickness of 300nm;

[0070] 2) Spin-coat 200nm thick PMMA glue on SiO 2 layer surface, and then grow a layer of low-temperature SiO on the PMMA surface by plasma-enhanced chemical vapor deposition 2 The barrier layer has a thickness of 30nm, and then spin-coats a 30nm thick UV-curable adhesive on the surface of the barrier layer;

[0071] 3) Using UV-NIL technology, the pre-prepared and anti-adhesive treated soft t...

Embodiment 2

[0083] The steps of this embodiment are basically the same as those of Embodiment 1, the difference is that the Al composition x of the GaN / AlN / AlGaN epitaxial substrate is selected to be 0.18, the thickness of the AlGaN epitaxial layer is 1-1.5 μm, and the etching time of ICP is 10 minutes. The modification time of the corresponding inorganic alkali solution is 4min.

[0084] The prepared AlGaN nanocolumn array structure is as follows Figure 16 As shown in , its cathodofluorescence spectrum is shown in Figure 23 As shown in , the diameter of the nanocolumn array is 350 nm, the diameter of the AlxGa1-xN layer is 80 nm smaller than that of the AlN intercalation layer, the period is 700 nm, and the height is 1.1–1.6 μm.

Embodiment 3

[0086] The steps of this example are basically the same as those of Example 1, the difference is that the Al composition x of the GaN / AlN / AlGaN epitaxial substrate is selected as 0.3, the thickness of the AlGaN epitaxial layer is 0.5-1 μm, and the etching time of ICP is 12 minutes. The modification time of the inorganic alkali solution is 2min.

[0087]The diameter of the prepared AlGaN nanocolumn array is 300nm, the diameter of the AlxGa1-xN layer is 50nm smaller than that of the AlN insertion layer, the period is 600nm, and the height is 0.6-1.1μm. Its structure is as follows Figure 17 As shown in , its cathodofluorescence spectrum is shown in Figure 24 shown in .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com