A small prism upper plate control tooling for side sagging

A technology of controlling side and prism, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of high scrap rate, product accuracy can not meet the requirements of drawings, long turnaround time, etc., to reduce production costs, shorten production cycle, The effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

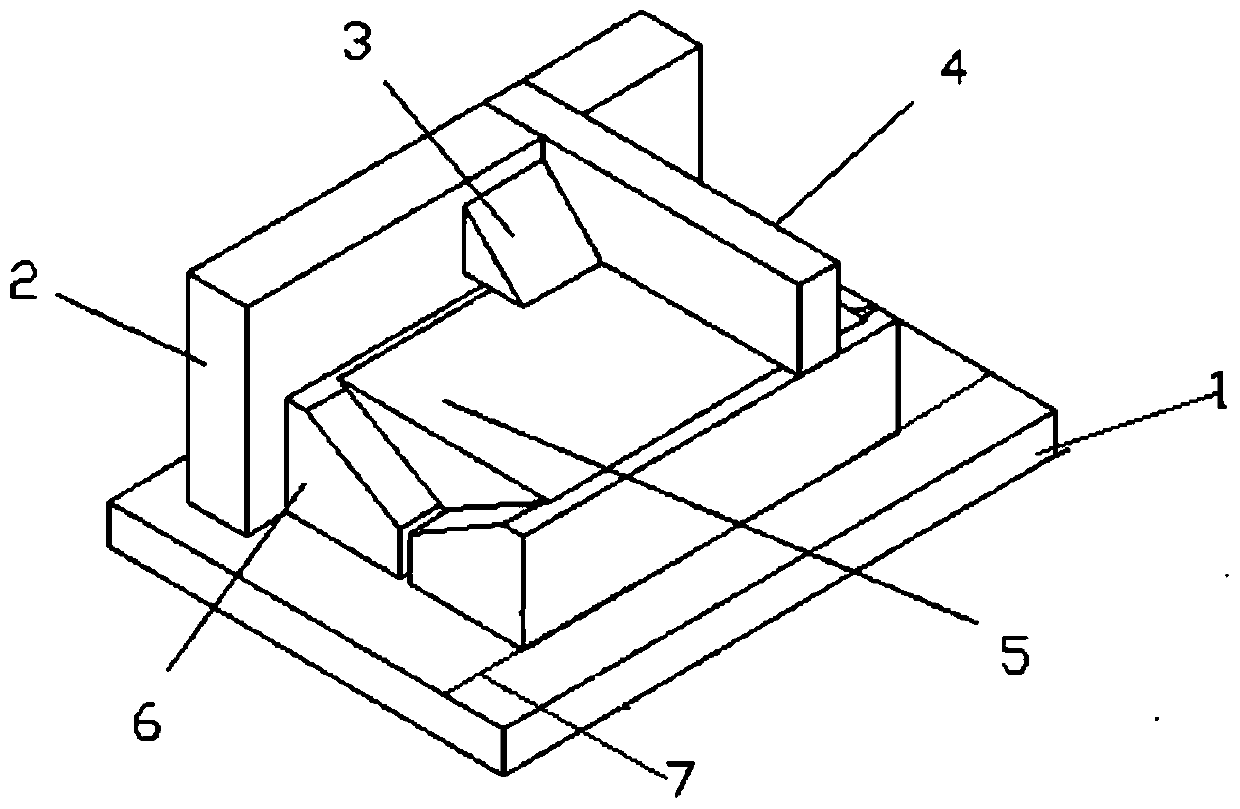

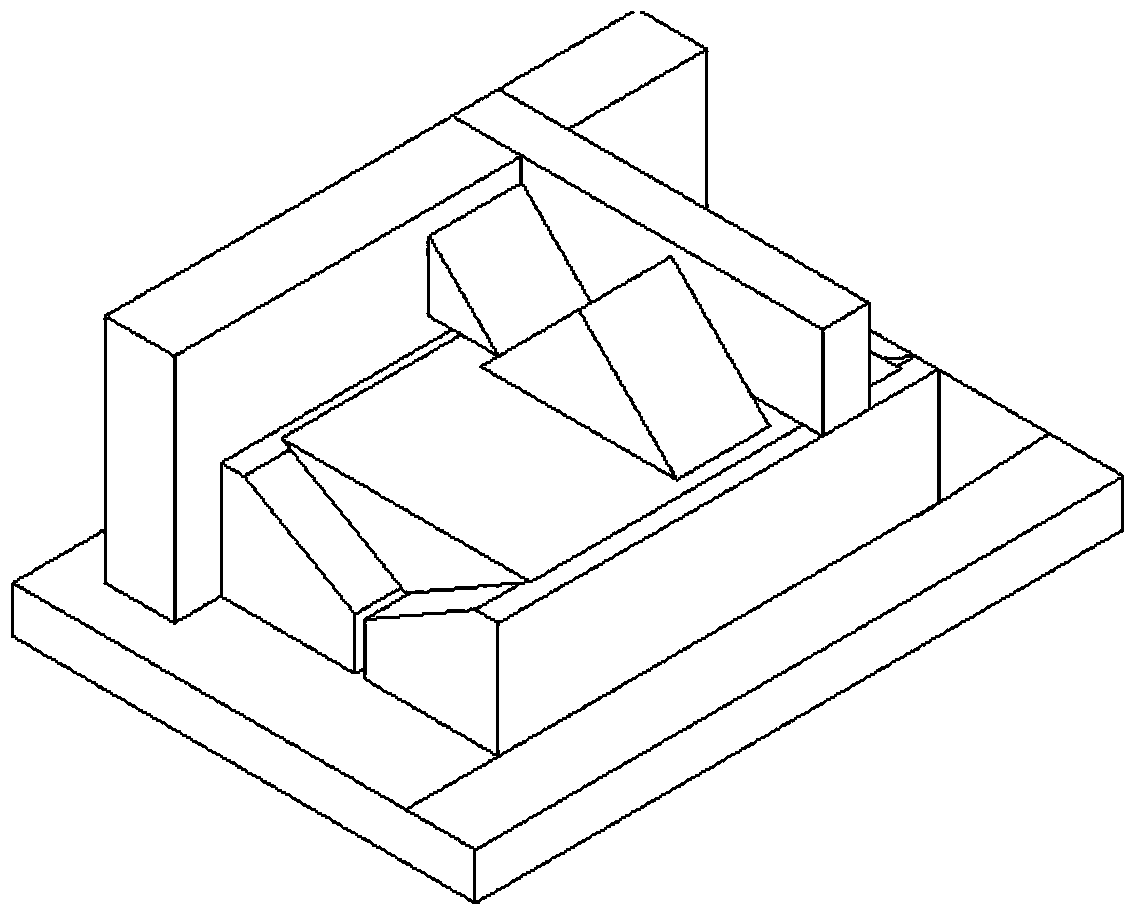

[0035] Such as figure 1As shown, a small prism upper plate control side sagging frock of this embodiment includes a base 1, a horizontal positioning block 2, a stopper 4 and a horizontal support body 5, and also includes a V-shaped limit block 6, a limit block 3 and positioning marking line 7, wherein base 1, horizontal positioning block 2, block 4, limiting block 3, horizontal body 5 and V-shaped limiting block 6 are made of colorless optical glass; the V-shaped limiting The block 6 is a V-shaped groove structure with an opening angle of 90°, the specification is 160*120*40mm, the tolerance is ±0.01mm, the right angle accuracy is ±30", and one side of the bottom surface extends the positioning mark line 7 and the base 1 Glue and fix the connection with optical glue, one of the rectangular sides is closely attached to the horizontal positioning block 2, and is lower than the height of the wide surface of the horizontal positioning block 2, ensuring that the sagittal height of ...

Embodiment 2

[0044] The specific structure of a small prism upper plate control side sagging frock of this embodiment is basically the same as that of embodiment 1, the difference is that it also includes a spirit level; The V-shaped groove structure uses local materials and does not need to make special limit blocks, which reduces the production cost.

[0045] In this embodiment, a small prism upper plate controls the side sag, and the basic usage steps are the same as those in Embodiment 1, the difference is that the entire tooling is calibrated with a spirit level before pasting the small prism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com