Copper-doped manganese dioxide catalyst and preparation method therefor

A manganese dioxide and catalyst technology, applied in the field of copper-doped manganese dioxide catalyst material and its preparation, can solve the problems of low doping amount of manganese cerium catalyst and difficulty in controlling the doping amount, and achieve high doping degree , the effect of high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

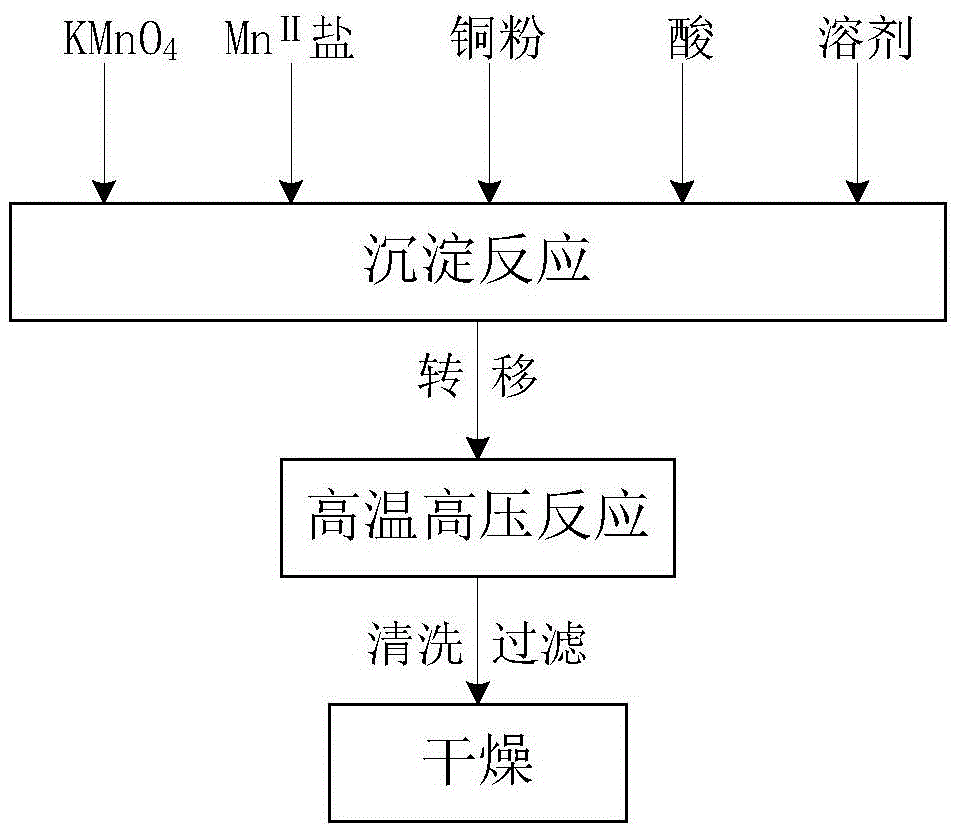

Method used

Image

Examples

Embodiment 1

[0029] Add 14.35g of manganese nitrate hexahydrate, 15.8g of potassium permanganate and 0.96g of copper powder into 400g of pure water, stir, and add nitric acid to adjust the pH of the solution to 2.0. Continue to stir to make it react at 0°C for 30 hours, then transfer the mixed solution and internally generated intermediate products to the reaction kettle, then place the above reaction kettle at 200°C for 1 hour reaction, take it out after the reaction is completed and cool, and clean , filtering and drying the resulting filter residue to obtain the copper-doped manganese dioxide catalyst material.

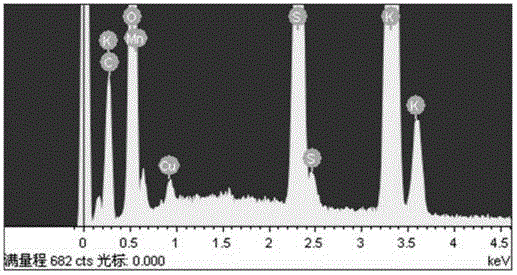

[0030] Through the energy spectrum test, the content of each component in the product of this embodiment is shown in Table 1, and the detailed energy spectrum is as shown in Table 1. figure 2 As shown, it shows that the synthesized copper-doped manganese dioxide catalyst material is a rod-shaped nanoscale material, and copper has been successfully doped into the lattice of man...

Embodiment 2

[0033] Add 1.98g manganese chloride tetrahydrate, 4.74g potassium permanganate and 0.64g copper powder to 370g pure water, stir, then add sulfuric acid to adjust the pH of the solution to 4.0. Continue to stir to make it react at 90°C for 1 hour, then transfer all the mixed solution and internally generated intermediate products to the reaction kettle, then place the reaction kettle at 150°C for 10 hours, take it out after the reaction is completed and cool, and clean , filtering and drying the resulting filter residue to obtain the copper-doped manganese dioxide catalyst material.

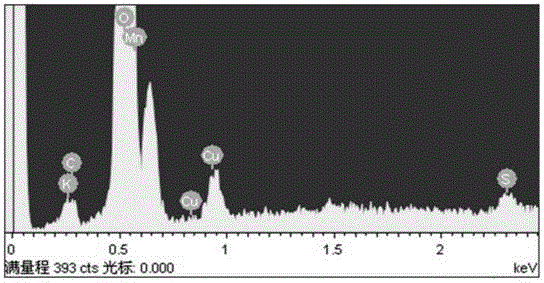

[0034] Through the energy spectrum test, the content of each component in the product of this embodiment is shown in Table 1, and the detailed energy spectrum is as shown in Table 1. image 3 As shown, it shows that the synthesized copper-doped manganese dioxide catalyst material is a rod-shaped nanoscale material, and copper has been successfully doped into the lattice of manganese dioxide.

[0...

Embodiment 3

[0037] Add 22.3g of manganese sulfate tetrahydrate, 18.96g of potassium permanganate and 3.2g of copper powder into 400g of pure water, stir, and then add hydrochloric acid to adjust the pH of the solution to 1.0. Continue to stir to make it react at room temperature for 15 hours, then transfer all the mixed solution and internally generated intermediate products to the reaction kettle, and then place the above reaction kettle at 100°C for 20 hours of reaction. After the reaction is completed, take it out after cooling, and clean it , filtering and drying the resulting filter residue to obtain the copper-doped manganese dioxide catalyst material.

[0038] The catalytic performance test is the same as in Example 1, and the test results show that the efficiency of the ultra-dispersed composite catalyst prepared in this example to catalyze and decompose 120 ppm of formaldehyde once at room temperature is 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com