Barrier membrane and preparation method thereof and secondary battery comprising barrier membrane

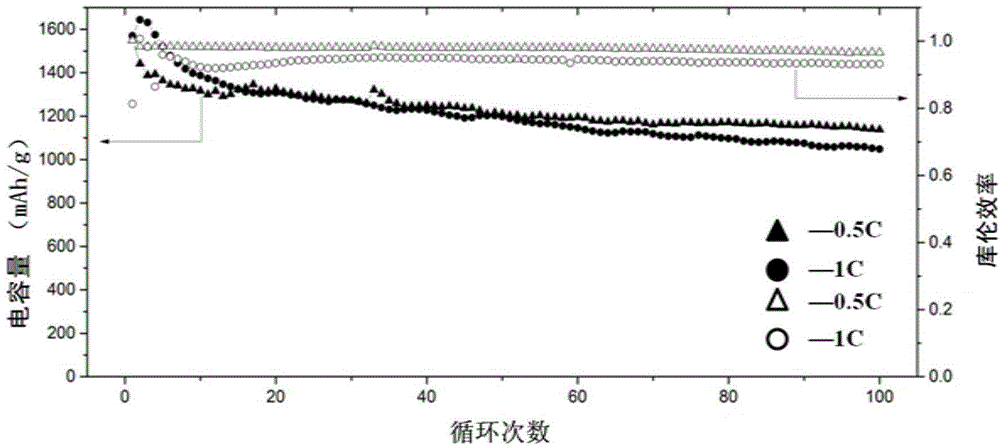

A secondary battery and diaphragm technology, which is applied in the field of secondary battery production, can solve the problems of secondary battery performance degradation, achieve the effects of improving battery performance, solving battery capacity and current efficiency reduction, and inhibiting the "shuttle" effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

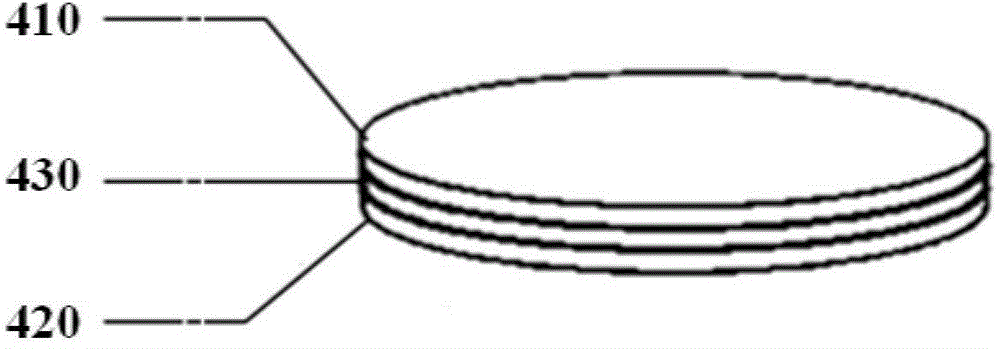

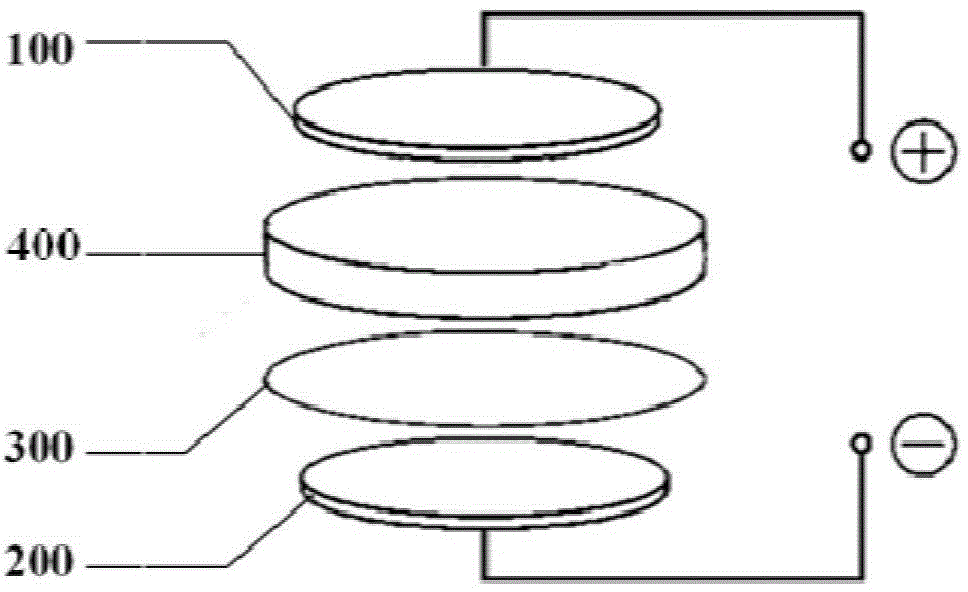

[0089] In addition, the present invention also provides a method for preparing a barrier diaphragm, which includes the following steps: preparing one or G layers of single-ion polymer electrolyte membrane, and pressing to form a barrier diaphragm; wherein G≥2.

[0090] The barrier diaphragm prepared by the above method of the present invention, the single-ion polymer electrolyte membrane has selective passage characteristics for cations, can hinder the electromigration of polysulfide anions in the electrolyte, and block them on the side close to the sulfur positive electrode. Under the joint action of the above adsorption and blocking, polysulfides and polysulfide anions can be effectively prevented from moving to the lithium negative electrode or the sodium negative electrode. Therefore, it is beneficial to suppress the "shuttle effect" in the secondary battery with sulfur as the positive electrode, and improve its battery performance. In the actual preparation process, those...

Embodiment 1

[0106] Prepare the barrier membrane:

[0107] With a specific surface area of 1264m 2 / g of commercial carbon black BP2000 as a conductive adsorption filler, with polytetrafluoroethylene as a polymer binder. The conductive adsorption filler is dissolved in the polymer binder emulsion (the mass ratio of the conductive adsorption filler to the polymer binder is 4:1) to form an adsorption emulsion. Then adopt isopropanol to demulsify, and the filtrate is pressed (pressure is 1Mpa) into the film of 0.6mm on the roller machine as the first adsorption layer and the second adsorption layer;

[0108] Perform lithium ion exchange treatment on the Nafion membrane to obtain a single-ion polymer electrolyte membrane;

[0109] The first adsorption layer, the single-ion polymer electrolyte membrane and the second adsorption layer of the same size were sequentially stacked, and then pressed on a roller machine with a pressure of 3Mpa to obtain a barrier diaphragm.

[0110] Preparation o...

Embodiment 2

[0115] Prepare the barrier membrane:

[0116] With a specific surface area of 1264m 2 / g of "pearl black" (English name blackpearl) BP2000 is used as a conductive adsorption filler, with polytetrafluoroethylene as a polymer binder. The conductive adsorption filler is dissolved in the polymer binder emulsion (the mass ratio of the conductive adsorption filler to the polymer binder is 3:1) to form an adsorption emulsion. Then adopt isopropanol to demulsify, and the filtrate is pressed (pressure is 3Mpa) into the film of 0.1mm on the roller machine as the first adsorption layer and the second adsorption layer;

[0117] preparation containing sp 3 Polymer lithium salt of hybrid boron anion, using hexamethyldisilazane to carry out silylation treatment on 2,5-dihydroxyterephthalic acid to obtain methylated product; Oxyboron lithium is polymerized to obtain the sp-containing structure of formula I 3 Polymeric Lithium Salts of Hybridized Boron Anions. 0.6g containing sp 3 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com